Question: Q . 4 . Mr . Hari Harsha, General Manager at Quicktronics, a contract manufacturer for consumer electronics was headed to the annual meeting. He

Q Mr Hari Harsha, General Manager at Quicktronics, a contract manufacturer for consumer electronics was headed to the annual meeting. He had the demand forecast for the next months and goal of the meeting was to set up sales and operations plan. Historically Mr Hlan lhad maintained a steady workforce of teams in the plant and had built inventory in the first half of the year for use in the second half of the year. Mr Hari walked into the meeting, be wondered whether the hiring and firing of workforce is better than inventory hold to meet demand in the second half of the year.

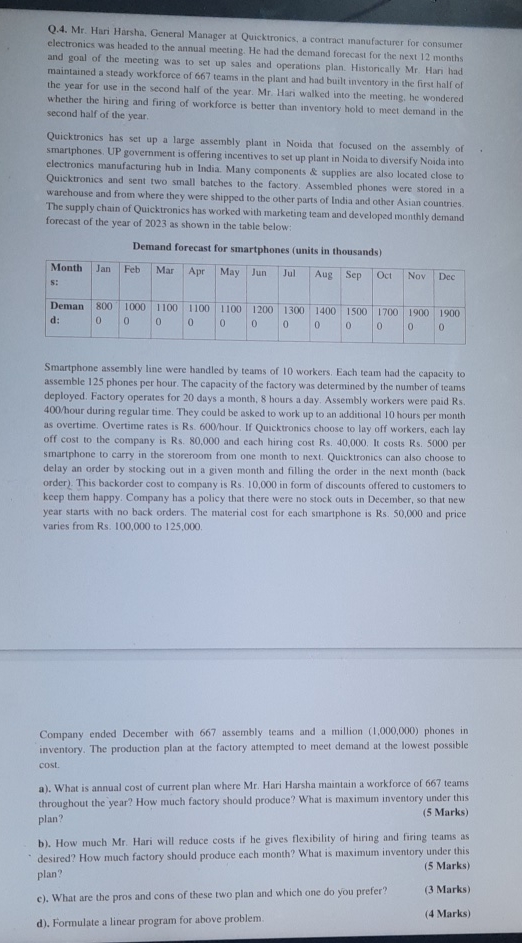

Quicktronics has set up a large assembly plant in Noida that focused on the assembly of smartphones. UP govermment is offering incentives to set up plant in Noida to diversify Noida into electronics manufacturing hub in India. Many components & supplies are also located close to Quicktronies and sent two small batches to the factory. Assembled phones were stored in a warehouse and from where they were shipped to the other parts of India aad other Asian countries. The supply chain of Quicktronics has worked with marketing team and developed monthly demand forecast of the year of as shown in the table below:

Demand forecast for smartphones units in thousands

tabletableMonths:Jan,Feb,Mar,Apr,May,Jun,Jul,Aug,Sep,Oct,Nov,DectableDemand:tabletabletabletabletabletabletabletabletabletabletabletable

Smartphone assembly line were handled by teams of workers. Each team had the capacity to assemble phones per hour. The capacity of the factory was determined by the number of teams deployed. Factory operates for days a month, hours a day. Assembly workers were paid Rshour during regular time. They could be asked to work up to an additional hours per month as overtime. Overtime rates is Rshour If Quicktronics choose to lay off workers, each lay off cost to the company is Rs and each hiring cost Rs It costs Rs per smartphone to carry in the storeroom from one month to next. Quicktronics can also choose to delay an order by stocking out in a given month and filling the order in the next month back order This backorder cost to company is Rs in form of discounts offered to customers to keep them happy. Company has a policy that there were no stock outs in December, so that new year starts with no back orders. The material cost for each smartphone is Rs and price varies from Rs to

Company ended December with assembly teams and a million phones in inventory. The production plan at the factory attempted to meet demand at the lowest possible cost.

a What is annual cost of current plan where Mr Hari Harsha maintain a workforce of teams throughout the year? How much factory should produce? What is maximum inventory under this plan?

Marks

b How much Mr Hari will reduce costs if he gives flexibility of hiring and firing teams as desired? How much factory should produce each month? What is maximum inventory under this plan?

Marks

c What are the pros and cons of these two plan and which one do you prefer?

Marks

d Formulate a linear program for above problem.

Marks

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock