Question: PLEASE ANSWER THE 2 QUESTION UNDER, THANK YOU ... CASE STUDY Smartphone Production at QuickTronics Rudy Hartono, general manager at QuickTronics, a contract manufacturer for

PLEASE ANSWER THE 2 QUESTION UNDER, THANK YOU ...

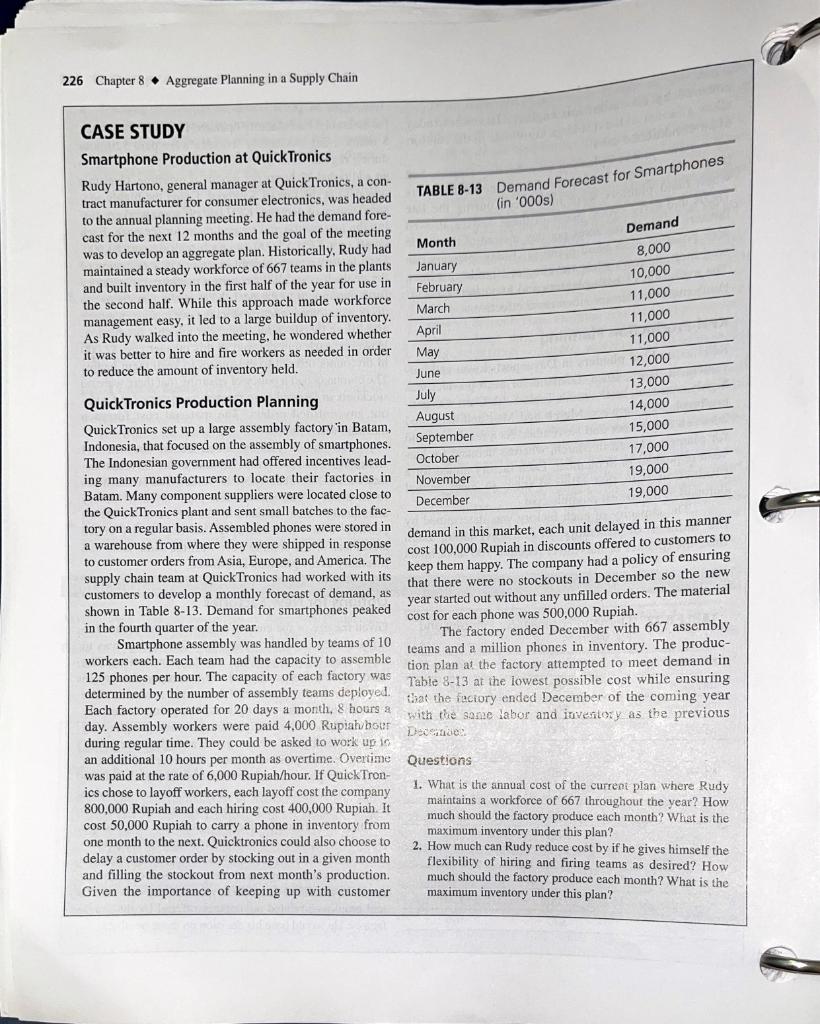

CASE STUDY Smartphone Production at QuickTronics Rudy Hartono, general manager at QuickTronics, a contract manufacturer for consumer electronics, was headed to the annual planning meeting. He had the demand forecast for the next 12 months and the goal of the meeting was to develop an aggregate plan. Historically, Rudy had maintained a steady workforce of 667 teams in the plants and built inventory in the first half of the year for use in the second half. While this approach made workforce management easy, it led to a large buildup of inventory. As Rudy walked into the meeting, he wondered whether it was better to hire and fire workers as needed in order to reduce the amount of inventory held. QuickTronics Production Planning QuickTronics set up a large assembly factory in Batam, Indonesia, that focused on the assembly of smartphones. The Indonesian government had offered incentives leading many manufacturers to locate their factories in Batam. Many component suppliers were located close to the QuickTronics plant and sent small batches to the factory on a regular basis. Assembled phones were stored in a warehouse from where they were shipped in response to customer orders from Asia, Europe, and America. The cost 100,000 Rupiah in discounts offered to customem happy. The company had a policy of ensuring customers to develop a monthly forecast of demand, as that there were no stockouts in December started out without any unfilled orders. The material shown in Table 8-13. Demand for smartphones peaked cost for each phone was 500,000 Rupiah. in the fourth quarter of the year. The factory ended December with 667 assembly Smartphone assembly was handled by teams of 10 teams and a million phones in inventory. The producworkers each. Each team had the capacity to assemble tion plan at the factory attempted to meet demand in 125 phones per hour. The capacity of each factory was Table 8-13 at the lowest possible cost while ensuring determined by the number of assembly teams deployed. that the factory ended December of the coming year Each factory operated for 20 days a month, 8 hours \& with the sane labor and inventory as the previous day. Assembly workers were paid 4,000 Rupiahbotr during regular time. They could be asked to work ug in an additional 10 hours per month as overtime. Overime Questions was paid at the rate of 6,000Rupiah/ hour. If QuickTronics chose to layoff workers, each layoff cost the company 1. What is the annual cost of the current plan where Rudy 800,000 Rupiah and each hiring cost 400,000 Rupiah. It maintains a workforce of 667 throughour the year? How cost 50,000 Rupiah to carry a phone in inventory from much should the factory produce each month? What is the one month to the next. Quicktronics could also choose to 2. How much can Rudy reduce cost by if he gives himself the delay a customer order by stocking out in a given month flexibility of hiring and firing teams as desired? How Given the importance of keeping should the factory produce each month? What is the maximum inventory under this plan

Step by Step Solution

There are 3 Steps involved in it

To solve these questions we need to calculate the costs associated with maintaining the current workforce and then compare it with the cost of a flexi... View full answer

Get step-by-step solutions from verified subject matter experts