Question: Q1. Consider the heat flow path, obtained during the continuous casting of metals through the cooled metal molds. In this case, Al is the metal

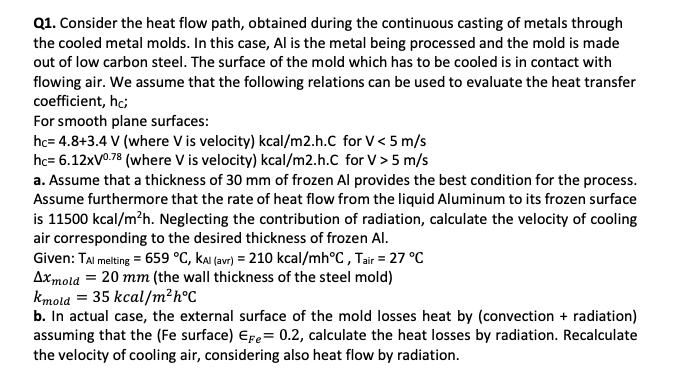

Q1. Consider the heat flow path, obtained during the continuous casting of metals through the cooled metal molds. In this case, Al is the metal being processed and the mold is made out of low carbon steel. The surface of the mold which has to be cooled is in contact with flowing air. We assume that the following relations can be used to evaluate the heat transfer coefficient, hci For smooth plane surfaces: hc= 4.8+3.4 V (where Vis velocity) kcal/m2.h.C for V5 m/s a. Assume that a thickness of 30 mm of frozen Al provides the best condition for the process. Assume furthermore that the rate of heat flow from the liquid Aluminum to its frozen surface is 11500 kcal/mh. Neglecting the contribution of radiation, calculate the velocity of cooling air corresponding to the desired thickness of frozen Al. Given: Tal melting = 659 C, kal (avr) = 210 kcal/mhC, Tair = 27 C Axmold = 20 mm (the wall thickness of the steel mold) kmold = 35 kcal/mhC b. In actual case, the external surface of the mold losses heat by (convection + radiation) assuming that the (Fe surface) Epe= 0.2, calculate the heat losses by radiation. Recalculate the velocity of cooling air, considering also heat flow by radiation

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts