Question: Q2. A speed reducer, shown below, made up from a flat belt + straight bevel + worm-gear set is driven by a 10HP, 2800rpm

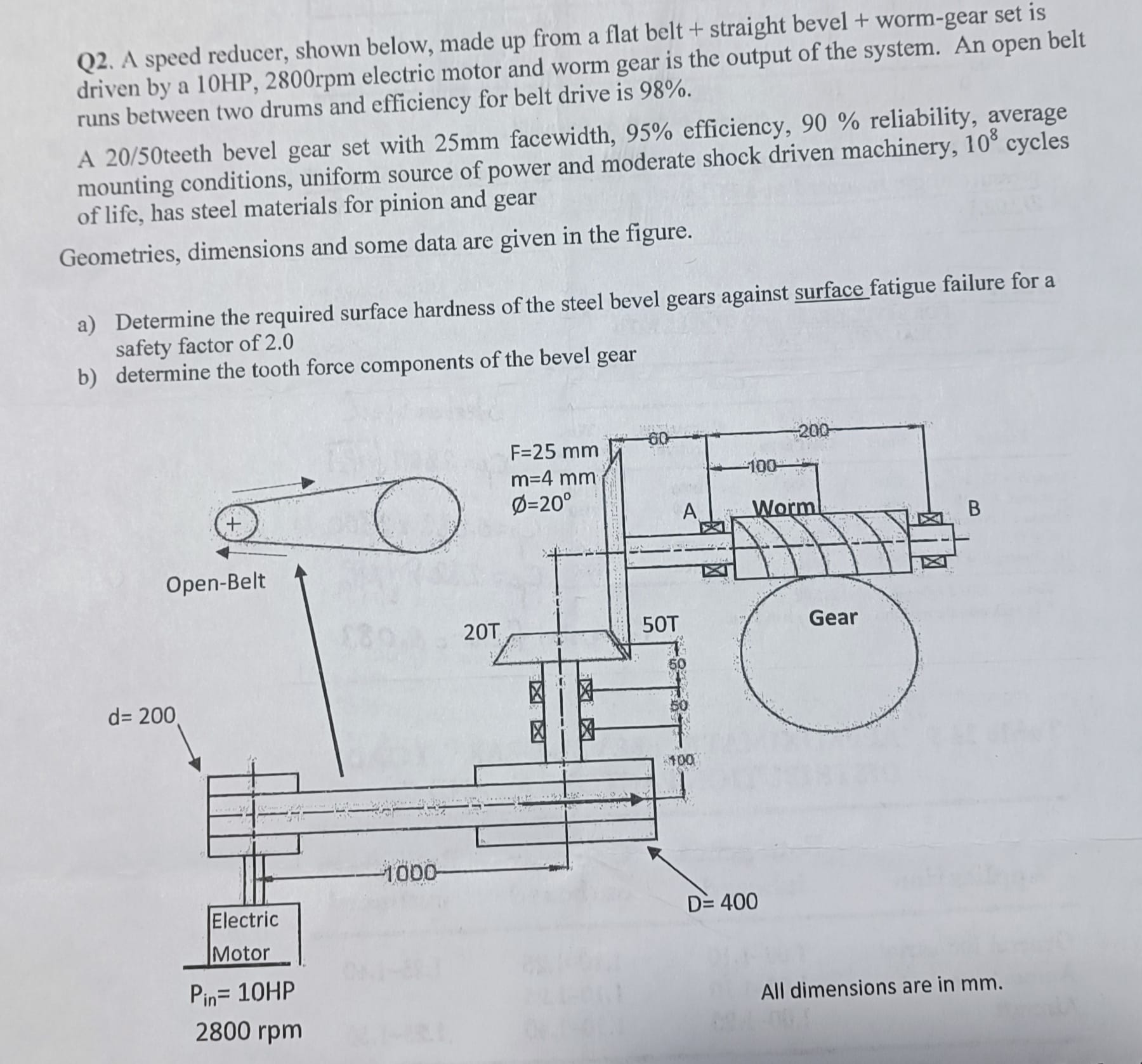

Q2. A speed reducer, shown below, made up from a flat belt + straight bevel + worm-gear set is driven by a 10HP, 2800rpm electric motor and worm gear is the output of the system. An runs between two drums and efficiency for belt drive is 98%. open belt A 20/50teeth bevel gear set with 25mm facewidth, 95% efficiency, 90 % reliability, average mounting conditions, uniform source of power and moderate shock driven machinery, 10 cycles of life, has steel materials for pinion and gear Geometries, dimensions and some data are given in the figure. a) Determine the required surface hardness of the steel bevel gears against surface fatigue failure for a safety factor of 2.0 b) determine the tooth force components of the bevel gear d= 200 Open-Belt Electric Motor Pin = 10HP 2800 rpm 1000- 60 200 F=25 mm 100 m=4 mm 0=20 A Worm B 20T 50T Gear 100 D= 400 All dimensions are in mm.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts