Question: Q2) In a food processing plant there is a need to heat 13.9kg /s of towns water from 10 to 70C. Steam at 2.7 bar

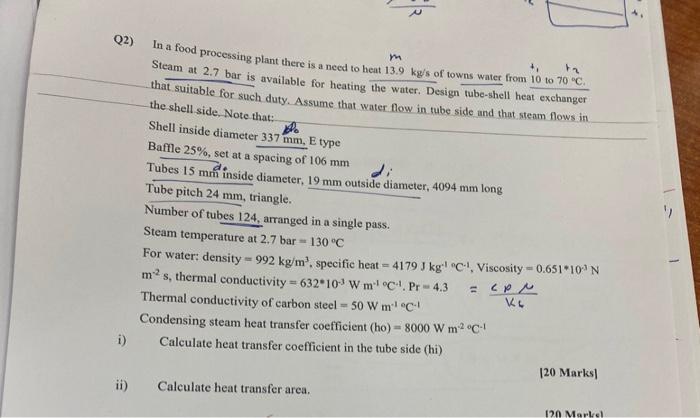

Q2) In a food processing plant there is a need to heat 13.9kg /s of towns water from 10 to 70C. Steam at 2.7 bar is available for heating the water. Design tube-shell heat exehanger that suitable for such duty. Assume that water flow in tube side and that steam flows in the shell side. Note that: Shell inside diameter 337mm, E type Baffle 25%, set at a spacing of 106mm Tubes 15mm inside diameter, 19mm outside diameter, 4094mm long Tube pitch 24mm, triangle. Number of tubes 124 , arranged in a single pass. Steam temperature at 2.7 bar =130C For water: density =992kg/m3, specific heat =4179Jkg11C1, Viscosity =0.651103N m2s, thermal conductivity =632103Wm1C1Pr=4.3=KL Thermal conductivity of carbon steel =50Wm1C1 Condensing steam heat transfer coefficient (ho) =8000Wm2.C1 i) Calculate heat transfer coefficient in the tube side (hi) [20 Marks] ii) Calculate heat transfer area

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts