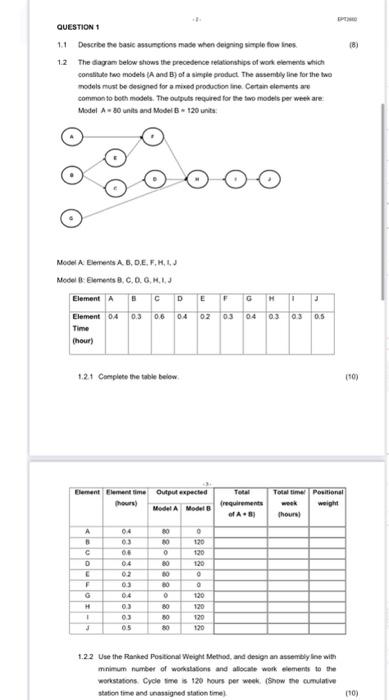

Question: QUESTION 1 1.1 Describe the basic assumptions made when deigning simple flow Ines. (8) 1.2 The diagram below shows the precedence relationships of work elements

QUESTION 1 1.1 Describe the basic assumptions made when deigning simple flow Ines. (8) 1.2 The diagram below shows the precedence relationships of work elements which constitute two models (A and B) of a simple product. The assembly line for the two models must be designed for a mixed production line. Certain elements are common to both models. The outputs required for the two models per week are Model A-80 units and Model B 120 units: Model A Elements A, B, D.E, F, H, I, J Model B: Elements B, C, D, G, H, I, J Element AB E H 1 J Element 0.4 0.3 0.6 0.4 02 0.3 03 0.5 Time (hour) 1.2.1 Complete the table below Element Element time Output expected Total time Positional (hours) wook weight Model A Model B (hours) A 04 80 O B 0.3 80 120 0.6 0 120 D 04 80 120 E 02 O F 0.3 0 G 0.4 120 H 0.3 120 T 0.3 120 3 0.5 80 120 1.22 Use the Ranked Positional Weight Method, and design an assembly line with minimum number of workstations and allocate work elements to the workstations Cycle time is 120 hours per week. (Show the cumulative station time and unassigned station time) (10) 228 888 80 80 80 80 F 0.3 EPT Total (requirements of A+B) (10) QUESTION 1 1.1 Describe the basic assumptions made when deigning simple flow Ines. (8) 1.2 The diagram below shows the precedence relationships of work elements which constitute two models (A and B) of a simple product. The assembly line for the two models must be designed for a mixed production line. Certain elements are common to both models. The outputs required for the two models per week are Model A-80 units and Model B 120 units: Model A Elements A, B, D.E, F, H, I, J Model B: Elements B, C, D, G, H, I, J Element AB E H 1 J Element 0.4 0.3 0.6 0.4 02 0.3 03 0.5 Time (hour) 1.2.1 Complete the table below Element Element time Output expected Total time Positional (hours) wook weight Model A Model B (hours) A 04 80 O B 0.3 80 120 0.6 0 120 D 04 80 120 E 02 O F 0.3 0 G 0.4 120 H 0.3 120 T 0.3 120 3 0.5 80 120 1.22 Use the Ranked Positional Weight Method, and design an assembly line with minimum number of workstations and allocate work elements to the workstations Cycle time is 120 hours per week. (Show the cumulative station time and unassigned station time) (10) 228 888 80 80 80 80 F 0.3 EPT Total (requirements of A+B)