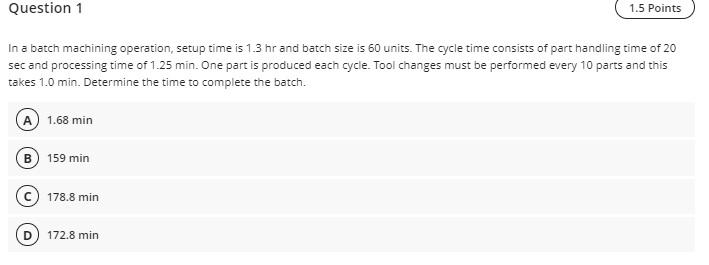

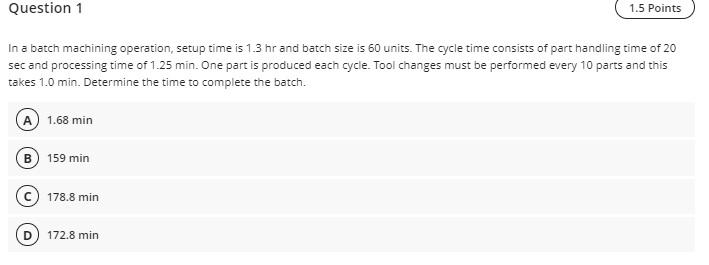

Question: Question 1 1.5 Points In a batch machining operation, setup time is 1.3 hr and batch size is 50 units. The cycle time consists of

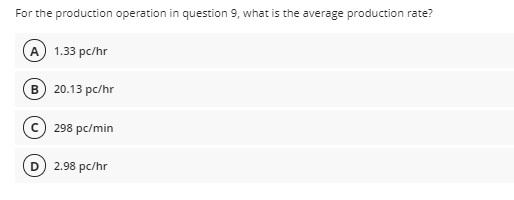

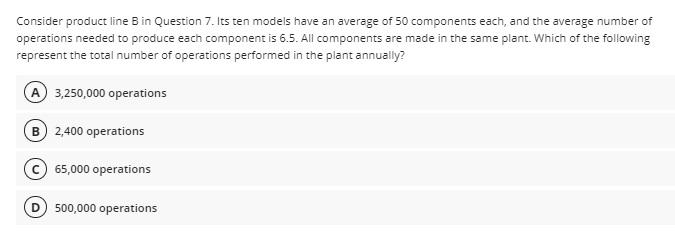

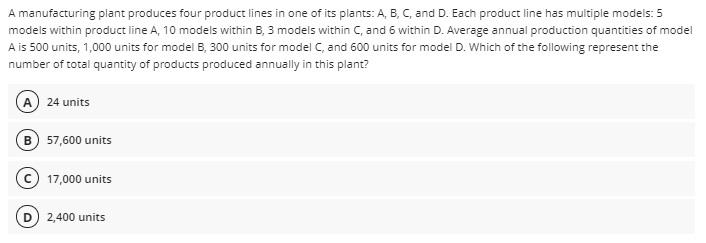

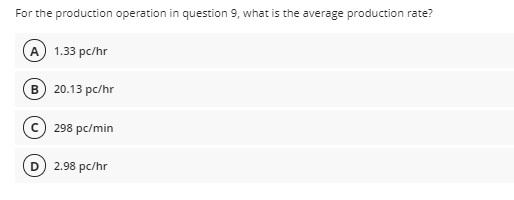

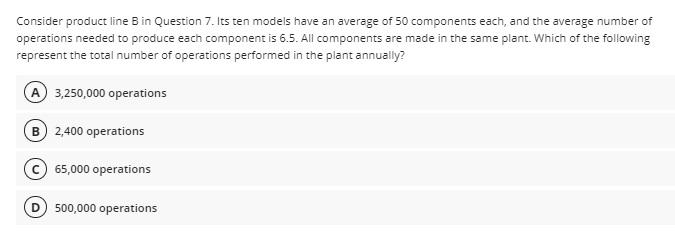

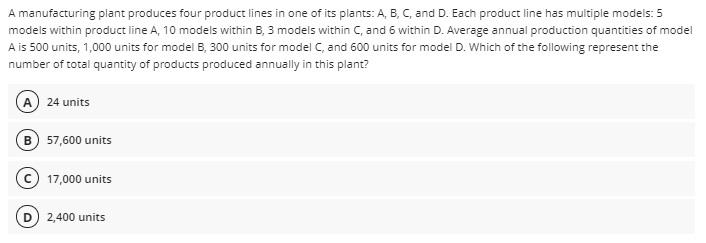

Question 1 1.5 Points In a batch machining operation, setup time is 1.3 hr and batch size is 50 units. The cycle time consists of part handling time of 20 sec and processing time of 1.25 min. One part is produced each cycle. Tool changes must be performed every 10 parts and this takes 1.0 min. Determine the time to complete the batch. 1.68 min B 159 min 178.8 min 172.8 min For the production operation in question 9, what is the average production rate? A 1.33 pc/hr B 20.13 pc/hr 298 pc/min 2.98 pc/hr Consider product line 3 in Question 7. Its ten models have an average of 50 components each, and the average number of operations needed to produce each component is 6.5. All components are made in the same plant. Which of the following represent the total number of operations performed in the plant annually? A 3,250,000 operations B 2,400 operations 65,000 operations 500,000 operations A manufacturing plant produces four product lines in one of its plants: A, B, C and D. Each product line has multiple models: 5 models within product line A, 10 models within B, 3 models within C and 6 within D. Average annual production quantities of model A is 500 units, 1,000 units for model B, 300 units for model Cand 600 units for model D. Which of the following represent the number of total quantity of products produced annually in this plant? A) 24 units B 57,600 units 17,000 units 2,400 units Question 1 1.5 Points In a batch machining operation, setup time is 1.3 hr and batch size is 50 units. The cycle time consists of part handling time of 20 sec and processing time of 1.25 min. One part is produced each cycle. Tool changes must be performed every 10 parts and this takes 1.0 min. Determine the time to complete the batch. 1.68 min B 159 min 178.8 min 172.8 min For the production operation in question 9, what is the average production rate? A 1.33 pc/hr B 20.13 pc/hr 298 pc/min 2.98 pc/hr Consider product line 3 in Question 7. Its ten models have an average of 50 components each, and the average number of operations needed to produce each component is 6.5. All components are made in the same plant. Which of the following represent the total number of operations performed in the plant annually? A 3,250,000 operations B 2,400 operations 65,000 operations 500,000 operations A manufacturing plant produces four product lines in one of its plants: A, B, C and D. Each product line has multiple models: 5 models within product line A, 10 models within B, 3 models within C and 6 within D. Average annual production quantities of model A is 500 units, 1,000 units for model B, 300 units for model Cand 600 units for model D. Which of the following represent the number of total quantity of products produced annually in this plant? A) 24 units B 57,600 units 17,000 units 2,400 units