Question: Question 1. Aggregate Planning (25 marks) M is a company that produces handbags. The company is trying to develop an aggregate plan for the next

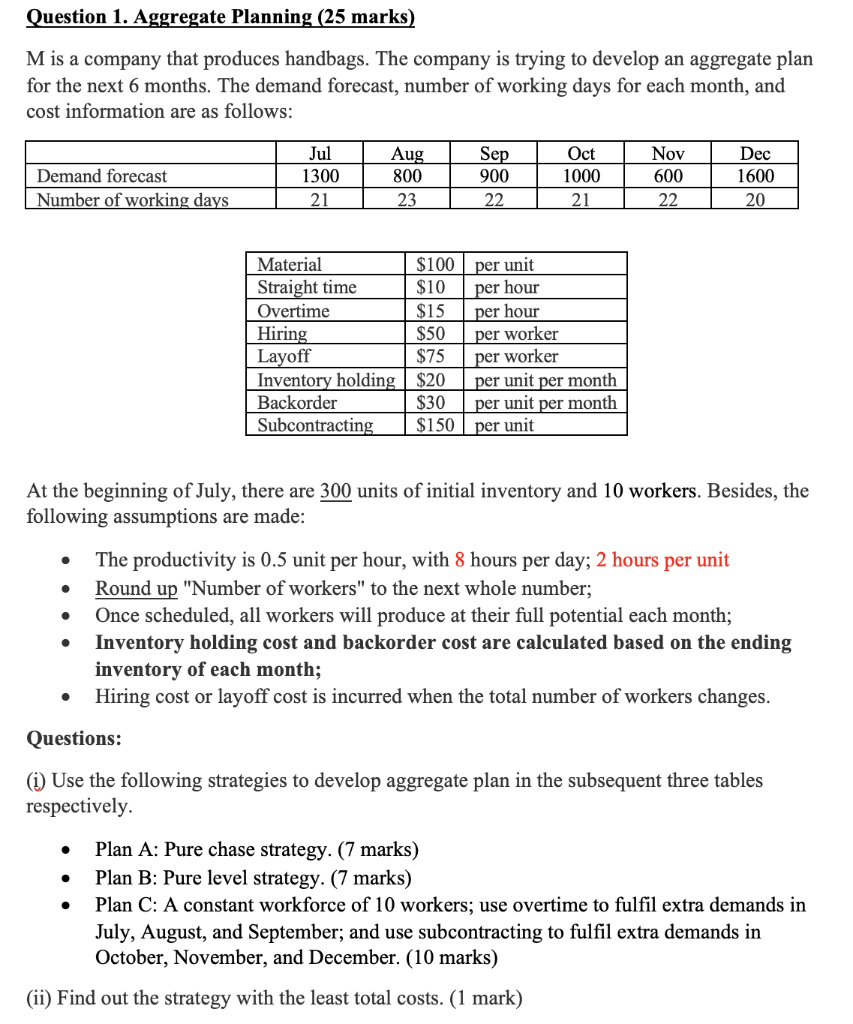

Question 1. Aggregate Planning (25 marks) M is a company that produces handbags. The company is trying to develop an aggregate plan for the next 6 months. The demand forecast, number of working days for each month, and cost information are as follows: Demand forecast Number of working days Jul 1300 21 Aug 800 23 Sep 900 22 Oct 1000 21 Nov 600 22 Dec 1600 20 per hour Material $100 per unit Straight time $10 Overtime $15 per hour Hiring $50 per worker Layoff $75 per worker Inventory holding $20 per unit per month Backorder $30 per unit per month Subcontracting $150 per unit At the beginning of July, there are 300 units of initial inventory and 10 workers. Besides, the following assumptions are made: . The productivity is 0.5 unit per hour, with 8 hours per day; 2 hours per unit Round up "Number of workers" to the next whole number; Once scheduled, all workers will produce at their full potential each month; Inventory holding cost and backorder cost are calculated based on the ending inventory of each month; Hiring cost or layoff cost is incurred when the total number of workers changes. . . Questions: (1) Use the following strategies to develop aggregate plan in the subsequent three tables respectively. Plan A: Pure chase strategy. (7 marks) Plan B: Pure level strategy. (7 marks) Plan C: A constant workforce of 10 workers; use overtime to fulfil extra demands in July, August, and September; and use subcontracting to fulfil extra demands in October, November, and December. (10 marks) (ii) Find out the strategy with the least total costs. (1 mark) Question 1. Aggregate Planning (25 marks) M is a company that produces handbags. The company is trying to develop an aggregate plan for the next 6 months. The demand forecast, number of working days for each month, and cost information are as follows: Demand forecast Number of working days Jul 1300 21 Aug 800 23 Sep 900 22 Oct 1000 21 Nov 600 22 Dec 1600 20 per hour Material $100 per unit Straight time $10 Overtime $15 per hour Hiring $50 per worker Layoff $75 per worker Inventory holding $20 per unit per month Backorder $30 per unit per month Subcontracting $150 per unit At the beginning of July, there are 300 units of initial inventory and 10 workers. Besides, the following assumptions are made: . The productivity is 0.5 unit per hour, with 8 hours per day; 2 hours per unit Round up "Number of workers" to the next whole number; Once scheduled, all workers will produce at their full potential each month; Inventory holding cost and backorder cost are calculated based on the ending inventory of each month; Hiring cost or layoff cost is incurred when the total number of workers changes. . . Questions: (1) Use the following strategies to develop aggregate plan in the subsequent three tables respectively. Plan A: Pure chase strategy. (7 marks) Plan B: Pure level strategy. (7 marks) Plan C: A constant workforce of 10 workers; use overtime to fulfil extra demands in July, August, and September; and use subcontracting to fulfil extra demands in October, November, and December. (10 marks) (ii) Find out the strategy with the least total costs. (1 mark)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts