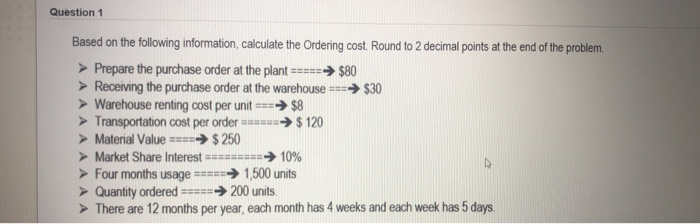

Question: Question 1 Based on the following information, calculate the Ordering cost. Round to 2 decimal points at the end of the problem. > Prepare the

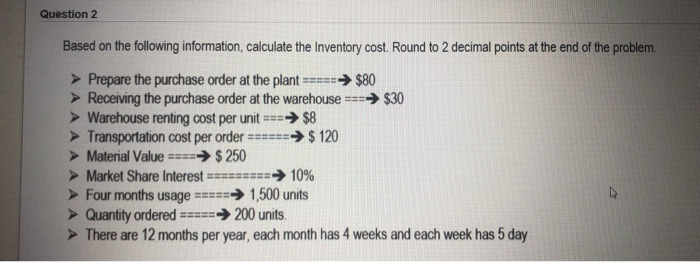

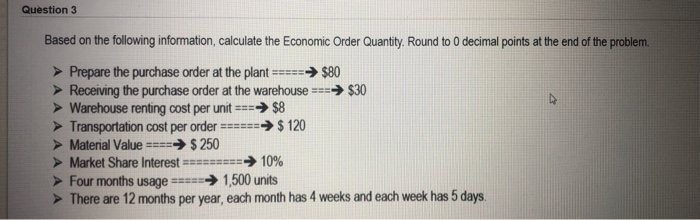

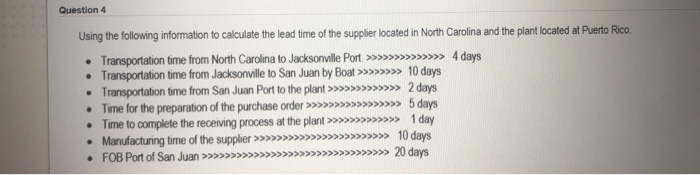

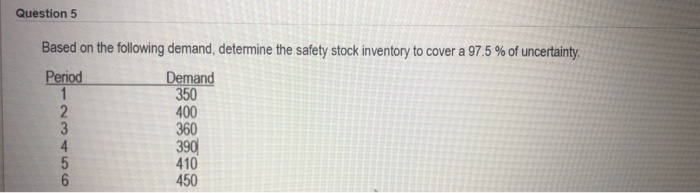

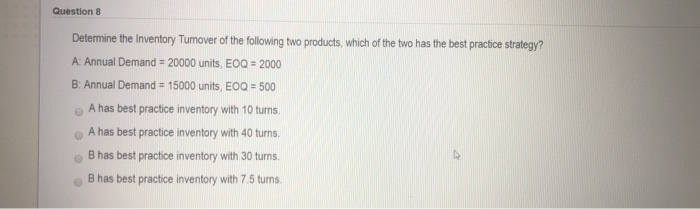

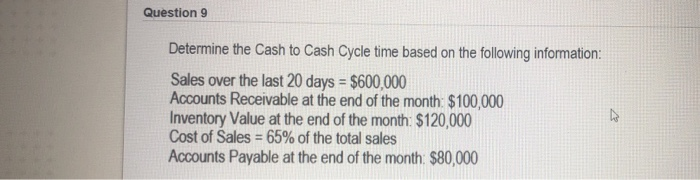

Question 1 Based on the following information, calculate the Ordering cost. Round to 2 decimal points at the end of the problem. > Prepare the purchase order at the plant =====> $80 > Receiving the purchase order at the warehouse ===> $30 > Warehouse renting cost per unit ===> $8 > Transportation cost per order = > Material Value === $ 250 > Market Share Interest= > Four months usage > Quantity ordered = > There are 12 months per year, each month has 4 weeks and each week has 5 days. $ 120 10% 1,500 units 200 units. Question 2 Based on the following information, calculate the Inventory cost. Round to 2 decimal points at the end of the problem. > Prepare the purchase order at the plant = > Receiving the purchase order at the warehouse ===> $30 > Warehouse renting cost per unit ===$8 > Transportation cost per order = > Material Value ====> $ 250 > Market Share Interest > Four months usage: > Quantity ordered =====> 200 units. There are 12 months per year, each month has 4 weeks and each week has 5 day > $80 $ 120 10% 1,500 units Question 3 Based on the following information, calculate the Economic Order Quantity. Round to 0 decimal points at the end of the problem. > Prepare the purchase order at the plant > Receiving the purchase order at the warehouse ===> $30 > Warehouse renting cost per unit = Transportation cost per order = > Material Value ====> $ 250 > Market Share Interest = > Four months usage There are 12 months per year, each month has 4 weeks and each week has 5 days. > $80 $8 $ 120 10% 1,500 units Question 4 Using the following information to calculate the lead time of the supplier located in North Carolina and the plant located at Puerto Rico. Transportation time from North Carolina to Jacksonville Port >>>>>>>>>>>> 4 days Transportation time from Jacksonville to San Juan by Boat >>>>>> 10 days Transportation time from San Juan Port to the plant >>>>>>>>>>>>> 2 days Time for the preparation of the purchase order >>>>>>>>>>>>>>> 5 days Time to complete the receiving process at the plant >>>>>>>>> 1 day Manufacturing time of the supplier >>>>>> FOB Port of San Juan >>> >>> 10 days >>> 20 days Question 5 Based on the following demand, detemine the safety stock inventory to cover a 97.5 % of uncertainty. Period Demand 350 400 360 390 410 450 234456 With the following information determine the Reorder Point inventory. The lead time for the product is 25 days and has a safety stock of 125 units. The demand per month is 2500 units and each month has 24 production days. Answer: Question 7 Determine the average inventory if the demand of the product is 16000 units per year, a total of 10 orders were issued and they keep a safety stock of 200 units. Answer Question 8 Determine the Inventory Tumover of the following two products, which of the two has the best practice strategy? A: Annual Demand = 20000 units, EOQ = 2000 B: Annual Demand = 15000 units, EOQ = 500 A has best practice inventory with 10 turns. A has best practice inventory with 40 turns. B has best practice inventory with 30 turns. B has best practice inventory with 7.5 turns. Question 9 Determine the Cash to Cash Cycle time based on the following information: Sales over the last 20 days = $600,000 Accounts Receivable at the end of the month: $100,000 Inventory Value at the end of the month: $120,000 Cost of Sales = 65% of the total sales Accounts Payable at the end of the month: $80,000