Question: Question 1: For the given gear manufacturing facility, estimate the following. a) Number of people required for the facility if daily production requirement is 34290

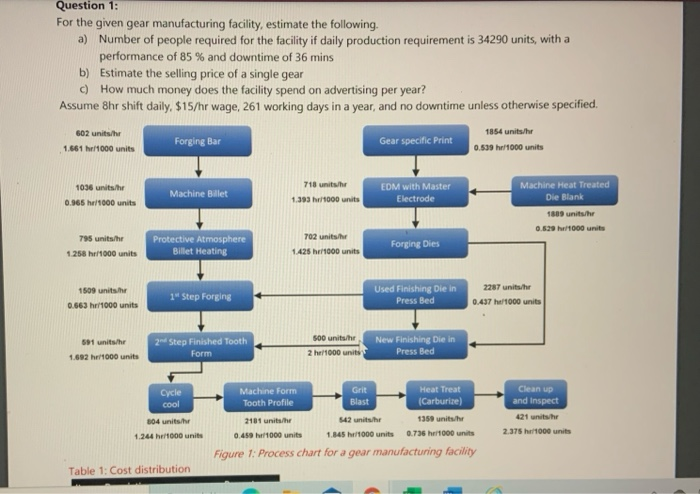

Question 1: For the given gear manufacturing facility, estimate the following. a) Number of people required for the facility if daily production requirement is 34290 units, with a performance of 85 % and downtime of 36 mins b) Estimate the selling price of a single gear c) How much money does the facility spend on advertising per year? Assume 8hr shift daily, $15/hr wage, 261 working days in a year, and no downtime unless otherwise specified, Forging Bar Gear specific Print 1.661 he/1000 units 602 units/he 1854 units/hr 0.539 1000 units 1036 units/hr 0.965 hr/1000 units Machine Billet 718 units/he 1.393 h/1000 units EDM with Master Electrode Machine Heat Treated Die Blank 1809 units/her 0.529 / 1000 units IH 795 units/he 1.258 hr/1000 units HA Protective Atmosphere Billet Heating 702 units.hr 1.425 h/1000 units Forging Dies 1509 units.hr 0.663 he/1000 units 1" Step Forging Used Finishing Die in Press Bed 2287 units/her 0.437/1000 units 591 units/her 1.602 h/1000 units 2nd step Finished Tooth Form 500 units/hr 2 r1000 units New Finishing Die in Press Bed Cycle cool 804 unitshe 1.244 1000 units Machine Form Grit Heat Treat Tooth Profile Blast (Carburize) 2181 units/he 542 units.hr 1359 units.hr 0.459/1000 units 1.845 h/1000 units 0.736 1000 units Figure 1: Process chart for a gear manufacturing facility Clean up and Inspect 421 units.hr 2.375 h/1000 units Table 1: Cost distribution Question 1: For the given gear manufacturing facility, estimate the following. a) Number of people required for the facility if daily production requirement is 34290 units, with a performance of 85 % and downtime of 36 mins b) Estimate the selling price of a single gear c) How much money does the facility spend on advertising per year? Assume 8hr shift daily, $15/hr wage, 261 working days in a year, and no downtime unless otherwise specified, Forging Bar Gear specific Print 1.661 he/1000 units 602 units/he 1854 units/hr 0.539 1000 units 1036 units/hr 0.965 hr/1000 units Machine Billet 718 units/he 1.393 h/1000 units EDM with Master Electrode Machine Heat Treated Die Blank 1809 units/her 0.529 / 1000 units IH 795 units/he 1.258 hr/1000 units HA Protective Atmosphere Billet Heating 702 units.hr 1.425 h/1000 units Forging Dies 1509 units.hr 0.663 he/1000 units 1" Step Forging Used Finishing Die in Press Bed 2287 units/her 0.437/1000 units 591 units/her 1.602 h/1000 units 2nd step Finished Tooth Form 500 units/hr 2 r1000 units New Finishing Die in Press Bed Cycle cool 804 unitshe 1.244 1000 units Machine Form Grit Heat Treat Tooth Profile Blast (Carburize) 2181 units/he 542 units.hr 1359 units.hr 0.459/1000 units 1.845 h/1000 units 0.736 1000 units Figure 1: Process chart for a gear manufacturing facility Clean up and Inspect 421 units.hr 2.375 h/1000 units Table 1: Cost distribution

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts