Question: Question 1 - Full Throttle Engineering Manufacturing Plan Full Throttle Engineering designs and produces parts for race teams across the country and the world. As

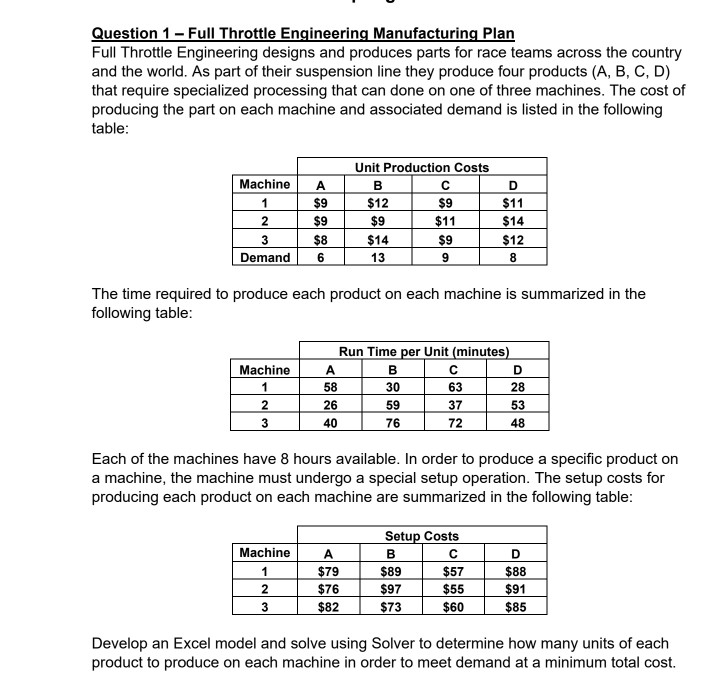

Question 1 - Full Throttle Engineering Manufacturing Plan Full Throttle Engineering designs and produces parts for race teams across the country and the world. As part of their suspension line they produce four products (A, B, C, D) that require specialized processing that can done on one of three machines. The cost of producing the part on each machine and associated demand is listed in the following table: Unit Production Costs Machine $9 $11 2 $9 $12 $9 $14 $11 $14 $8 $9 $12 Demand 6 9 The time required to produce each product on each machine is summarized in the following table: D Run Time per Unit (minutes) Machine A B 58 1 30 63 | 28 2 26 59 37 53 340 76 | 72 | 48 Each of the machines have 8 hours available. In order to produce a specific product on a machine, the machine must undergo a special setup operation. The setup costs for producing each product on each machine are summarized in the following table: Machine $79 $76 $82 Setup Costs B C $89 $57 $97 $55 $73 $60 D $88 $91 $85 2 3 Develop an Excel model and solve using Solver to determine how many units of each product to produce on each machine in order to meet demand at a minimum total cost

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock