Question: Background Specialized Racing Products (SRP) is a relatively small operation in Englewood, Colorado dedicated to providing the highest quality specialty products to sprint car racing

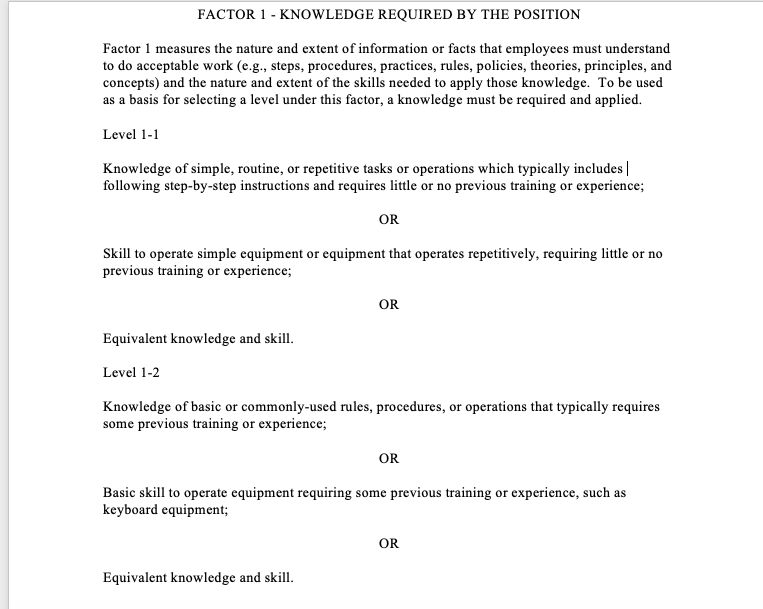

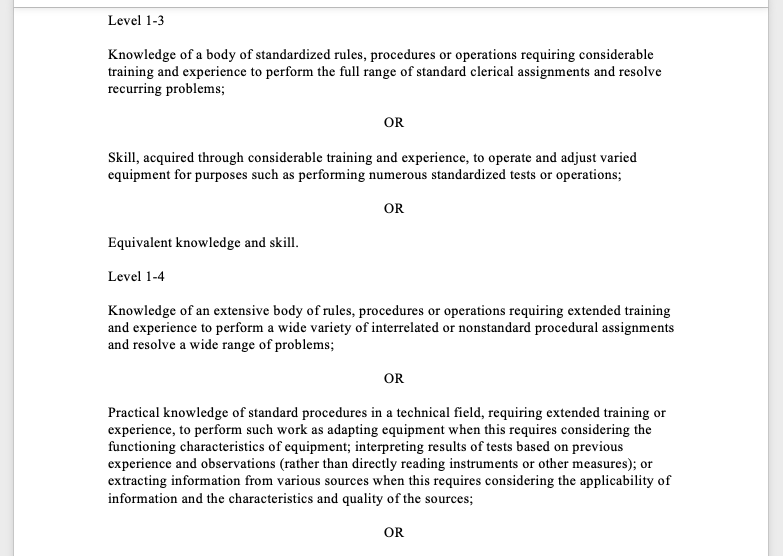

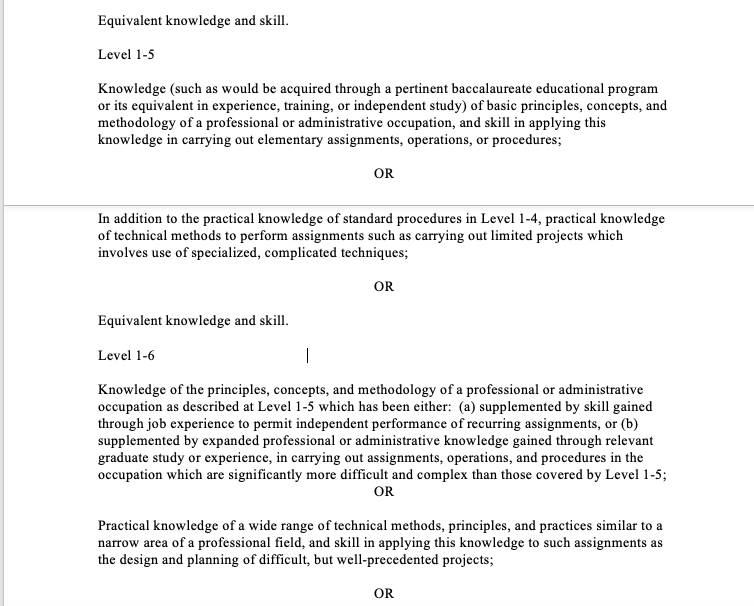

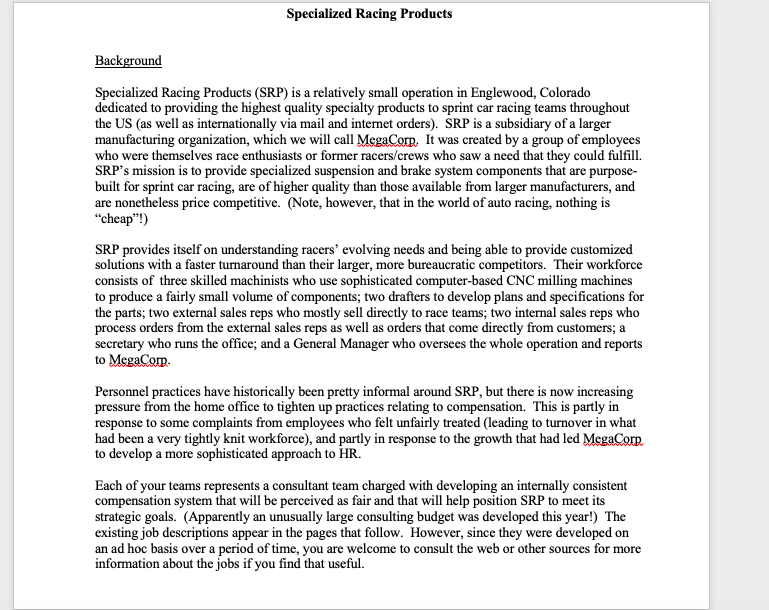

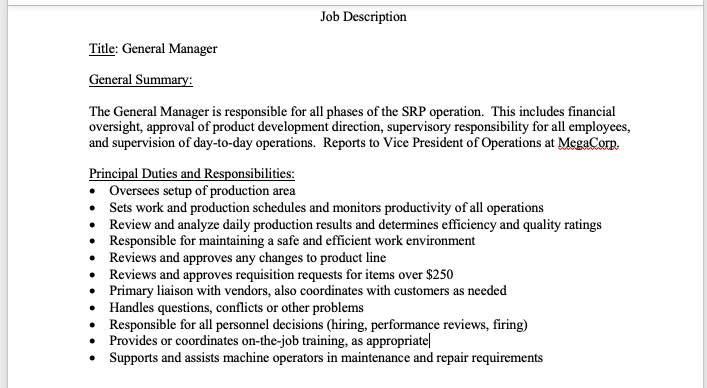

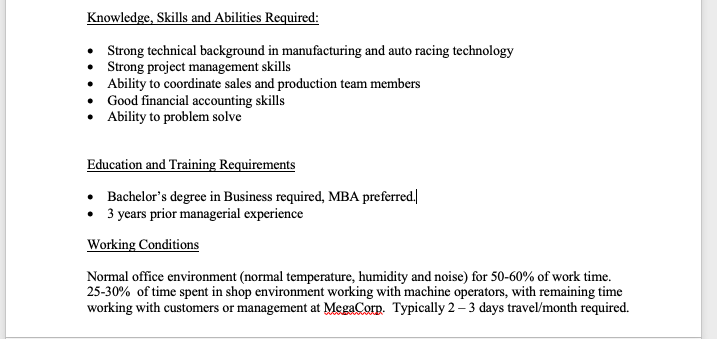

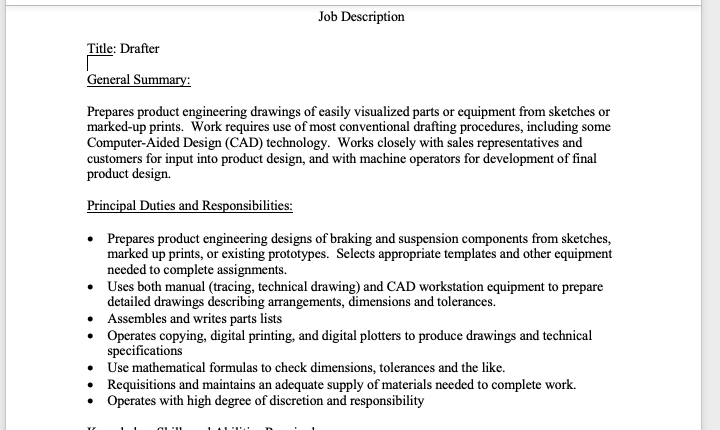

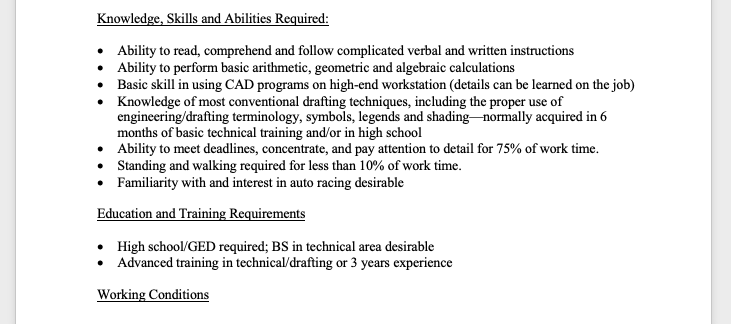

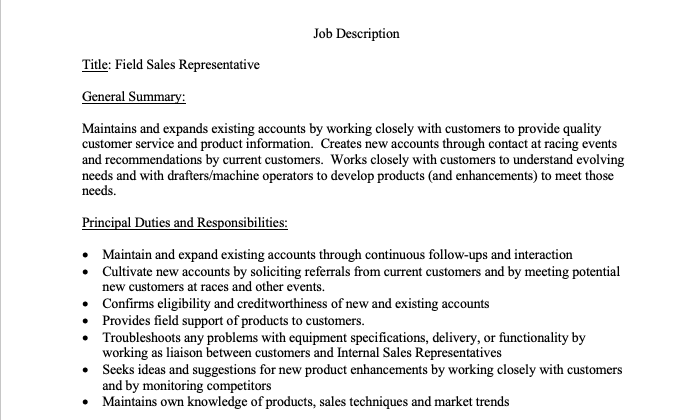

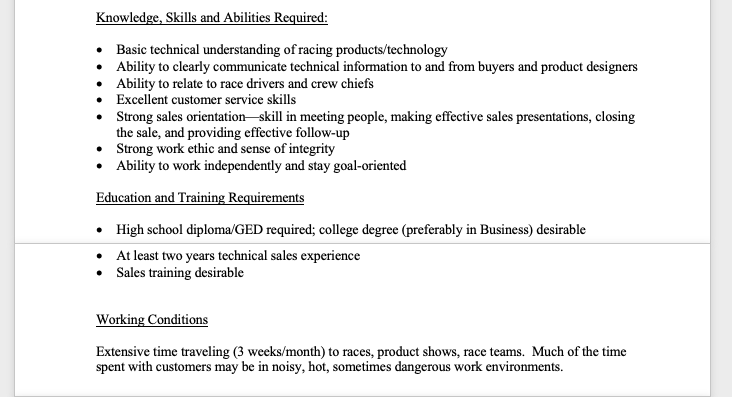

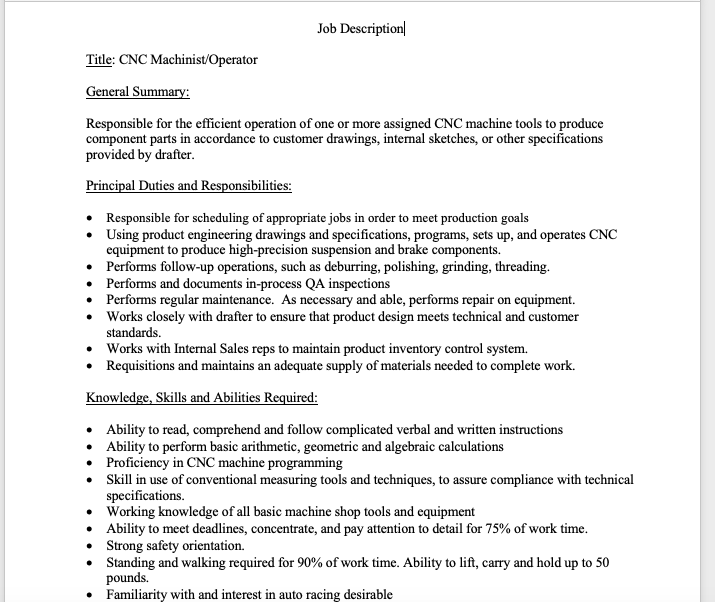

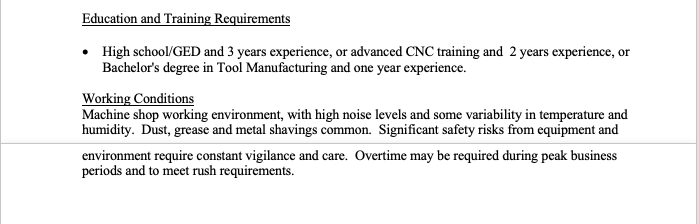

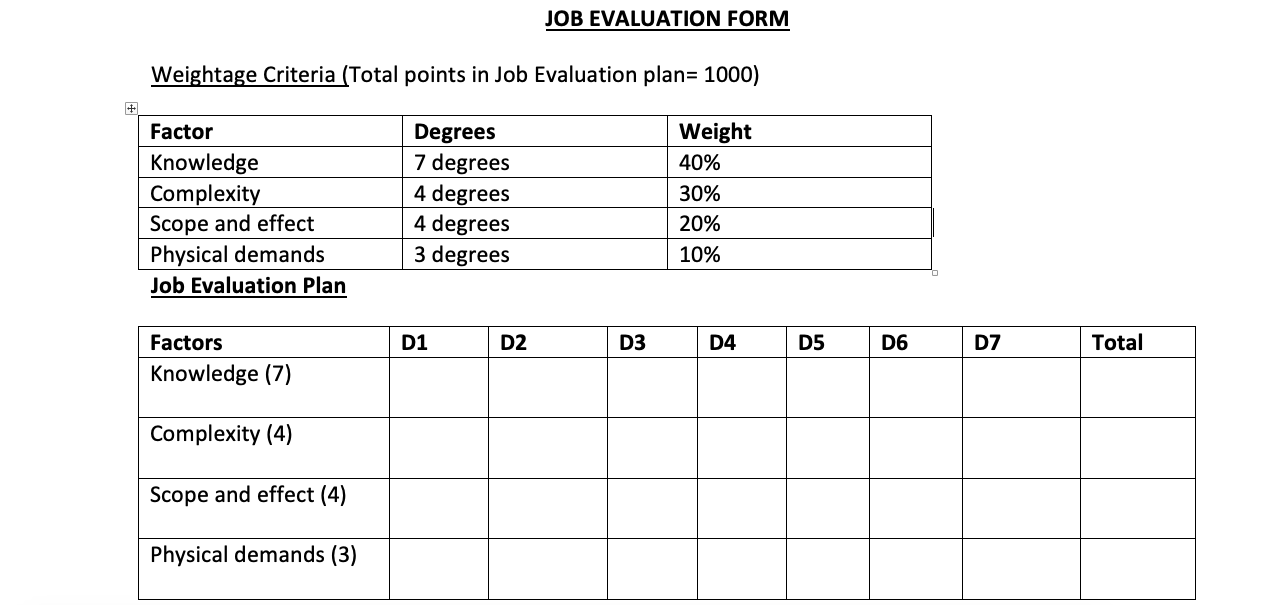

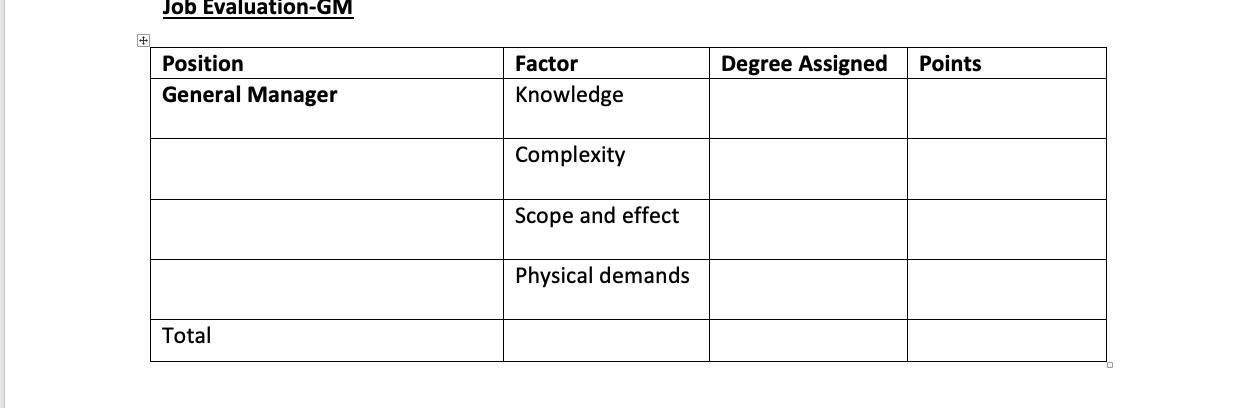

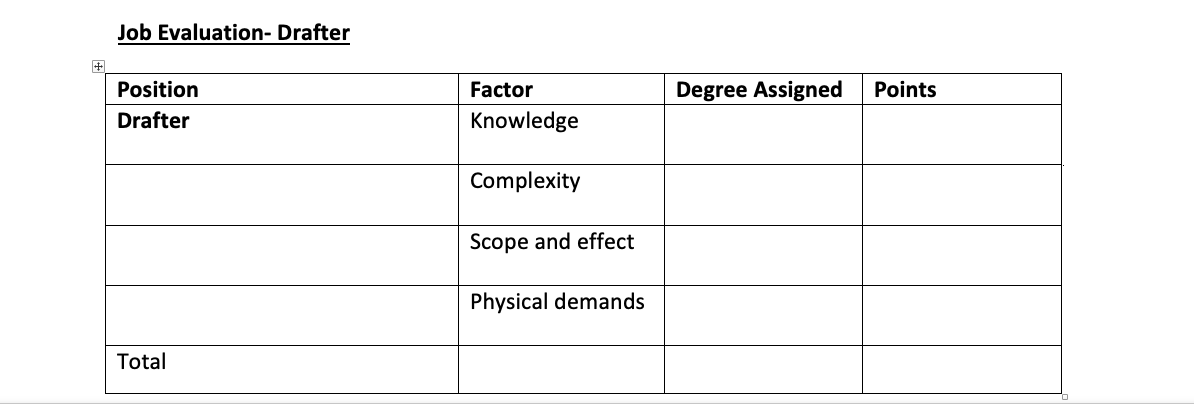

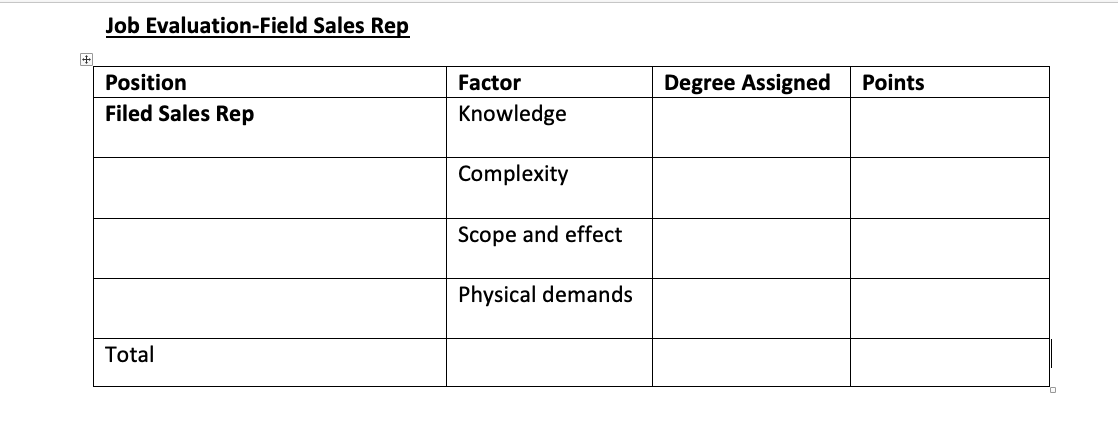

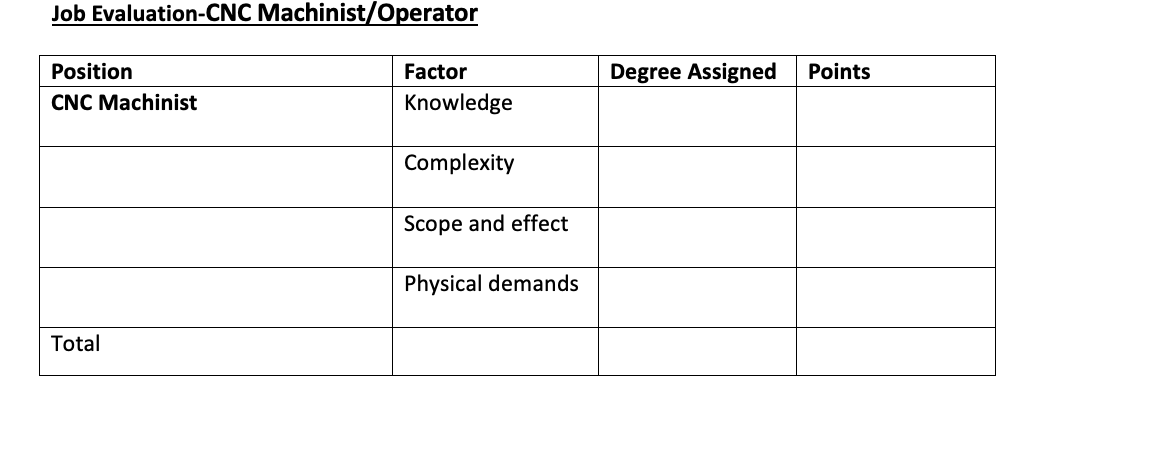

Background Specialized Racing Products (SRP) is a relatively small operation in Englewood, Colorado dedicated to providing the highest quality specialty products to sprint car racing teams throughout the US (as well as internationally via mail and internet orders). SRP is a subsidiary of a larger manufacturing organization, which we will call MegaCorp. It was created by a group of employees who were themselves race enthusiasts or former racers/crews who saw a need that they could fulfill. SRP's mission is to provide specialized suspension and brake system components that are purposebuilt for sprint car racing, are of higher quality than those available from larger manufacturers, and are nonetheless price competitive. (Note, however, that in the world of auto racing, nothing is "cheap"!) SRP provides itself on understanding racers' evolving needs and being able to provide customized solutions with a faster turnaround than their larger, more bureaucratic competitors. Their workforce consists of three skilled machinists who use sophisticated computer-based CNC milling machines to produce a fairly small volume of components; two drafters to develop plans and specifications for the parts; two external sales reps who mostly sell directly to race teams; two internal sales reps who process orders from the external sales reps as well as orders that come directly from customers; a secretary who runs the office; and a General Manager who oversees the whole operation and reports to MegaCorp. Personnel practices have historically been pretty informal around SRP, but there is now increasing pressure from the home office to tighten up practices relating to compensation. This is partly in response to some complaints from employees who felt unfairly treated (leading to turnover in what had been a very tightly knit workforce), and partly in response to the growth that had led MegaCorz to develop a more sophisticated approach to HR. Each of your teams represents a consultant team charged with developing an internally consistent compensation system that will be perceived as fair and that will help position SRP to meet its strategic goals. (Apparently an unusually large consulting budget was developed this year!) The existing job descriptions appear in the pages that follow. However, since they were developed on an ad hoc basis over a period of time, you are welcome to consult the web or other sources for more information about the jobs if you find that useful. FACTOR 1 - KNOWLEDGE REQUIRED BY THE POSITION Factor 1 measures the nature and extent of information or facts that employees must understand to do acceptable work (e.g., steps, procedures, practices, rules, policies, theories, principles, and concepts) and the nature and extent of the skills needed to apply those knowledge. To be used as a basis for selecting a level under this factor, a knowledge must be required and applied. Level 1-1 Knowledge of simple, routine, or repetitive tasks or operations which typically includes | following step-by-step instructions and requires little or no previous training or experience; OR Skill to operate simple equipment or equipment that operates repetitively, requiring little or no previous training or experience; OR Equivalent knowledge and skill. Level 1-2 Knowledge of basic or commonly-used rules, procedures, or operations that typically requires some previous training or experience; OR Basic skill to operate equipment requiring some previous training or experience, such as keyboard equipment; OR Equivalent knowledge and skill. Level 1-3 Knowledge of a body of standardized rules, procedures or operations requiring considerable training and experience to perform the full range of standard clerical assignments and resolve recurring problems; OR Skill, acquired through considerable training and experience, to operate and adjust varied equipment for purposes such as performing numerous standardized tests or operations; OR Equivalent knowledge and skill. Level 1-4 Knowledge of an extensive body of rules, procedures or operations requiring extended training and experience to perform a wide variety of interrelated or nonstandard procedural assignments and resolve a wide range of problems; OR Practical knowledge of standard procedures in a technical field, requiring extended training or experience, to perform such work as adapting equipment when this requires considering the functioning characteristics of equipment; interpreting results of tests based on previous experience and observations (rather than directly reading instruments or other measures); or extracting information from various sources when this requires considering the applicability of information and the characteristics and quality of the sources; OR Knowledge (such as would be acquired through a pertinent baccalaureate educational program or its equivalent in experience, training, or independent study) of basic principles, concepts, and methodology of a professional or administrative occupation, and skill in applying this knowledge in carrying out elementary assignments, operations, or procedures; OR In addition to the practical knowledge of standard procedures in Level 1-4, practical knowledge of technical methods to perform assignments such as carrying out limited projects which involves use of specialized, complicated techniques; OR Equivalent knowledge and skill. Level 1-6 Knowledge of the principles, concepts, and methodology of a professional or administrative occupation as described at Level 1-5 which has been either: (a) supplemented by skill gained through job experience to permit independent performance of recurring assignments, or (b) supplemented by expanded professional or administrative knowledge gained through relevant graduate study or experience, in carrying out assignments, operations, and procedures in the occupation which are significantly more difficult and complex than those covered by Level 1-5; OR Practical knowledge of a wide range of technical methods, principles, and practices similar to a narrow area of a professional field, and skill in applying this knowledge to such assignments as the design and planning of difficult, but well-precedented projects; Equivalent knowledge and skill. Level 1-7 Knowledge of a wide range of concepts, principles, and practices in a professional or administrative occupation, such as would be gained through extended graduate study or experience, and skill in applying this knowledge to difficult and complex work assignments; OR A comprehensive, intensive, practical knowledge of a technical field and skill in applying this knowledge to the development of new methods, approaches, or procedures; OR Equivalent knowledge and skill. FACTOR 2 - COMPLEXITY This factor covers the nature, number, variety, and intricacy of tasks, steps, processes, or methods in the work performed; the difficulty in identifying what needs to be done; and the difficulty and originality involved in performing the work. Level 2-1 The work consists of tasks that are clear-cut and directly related. There is little or no choice to be made in deciding what needs to be done. Actions to be taken or responses to be made are readily discernible. The work is quickly mastered. Level 2-2 The work consists of duties that involve related steps, processes, or methods. The decision regarding what needs to be done involves various choices requiring the employee to recognize the existence of and differences among a few easily recognizable situations. Actions to be taken or responses to be made differ in such things as the source of information, the kind of transactions or entries, or other differences of a factual nature. Level 2-3 The work includes various duties involving different and unrelated processes and methods. The decision regarding what needs to be done depends upon the analysis of the subject, phase, or issues involved in each assignment, and the chosen course of action may have to be selected from many alternatives. The work involves conditions and elements that must be identified and analyzed to discern interrelationships. Level 2-4 The work typically includes varied duties requiring many different and unrelated processes and methods such as those relating to well-established aspects of an administrative or professional field. Decisions regarding what needs to be done include the assessment of unusual circumstances, variations in approach, and incomplete or conflicting data. The work requires making many decisions concerning such things as the interpreting of considerable data, planning of the work, or refining the methods and techniques to be used. Scope and Effect covers the relationship between the nature of the work, i.e., the purpose, breadth, and depth of the assignment, and the effect of work products or services both within and outside the organization. Effect measures such things as whether the work output facilitates the work of others, provides timely services of a personal nature, or impacts on the adequacy of research conclusions. The concept of effect alone does not provide sufficient information to properly understand and evaluate the impact of the position. The scope of the work completes the picture, allowing consistent evaluations. Only the effect of properly performed work is to be considered. Level 3-1 The work involves the performance of specific, routine operations that include a few separate tasks or procedures. The work product or service is required to facilitate the work of others; however, it has little impact beyond the immediate organizational unit or beyond the timely provision of limited services to others. Level 3-2 The work involves the execution of specific rules, regulations, or procedures and typically comprises a complete segment of an assignment or project of broader scope. The work product or service affects the accuracy, reliability, or acceptability of further processes or services. Level 3-3 The work involves treating a variety of conventional problems, questions, or situations in conformance with established criteria. The work product or service affects the design or operation of systems, programs, or equipment; the adequacy of such activities as field investigations, testing operations, or research conclusions; or the social, physical, and economic well-being of persons. Level 3-4 The work involves establishing criteria; formulating projects; assessing program effectiveness; or investigating or analyzing a variety of unusual conditions, problems, or questions. The work product or service affects a wide range of agency activities, major activities of industrial concerns, or the operation of other agencies. FACTOR 4 - PHYSICAL DEMANDS The "Physical Demands" factor covers the requirements and physical demands placed on the employee by the work assignment. This includes physical characteristics and abilities (e.g., specific agility and dexterity requirements) and the physical exertion involved in the work (e.g., climbing, lifting, pushing, balancing, stooping, kneeling, crouching, crawling, or reaching). To some extent the frequency or intensity of physical exertion must also be considered, e.g., a job requiring prolonged standing involves more physical exertion than a job requiring intermittent standing. Background Specialized Racing Products (SRP) is a relatively small operation in Englewood, Colorado dedicated to providing the highest quality specialty products to sprint car racing teams throughout the US (as well as internationally via mail and internet orders). SRP is a subsidiary of a larger manufacturing organization, which we will call MegaCorp. It was created by a group of employees who were themselves race enthusiasts or former racers/crews who saw a need that they could fulfill. SRP's mission is to provide specialized suspension and brake system components that are purposebuilt for sprint car racing, are of higher quality than those available from larger manufacturers, and are nonetheless price competitive. (Note, however, that in the world of auto racing, nothing is "cheap"!) SRP provides itself on understanding racers' evolving needs and being able to provide customized solutions with a faster turnaround than their larger, more bureaucratic competitors. Their workforce consists of three skilled machinists who use sophisticated computer-based CNC milling machines to produce a fairly small volume of components; two drafters to develop plans and specifications for the parts; two external sales reps who mostly sell directly to race teams; two internal sales reps who process orders from the external sales reps as well as orders that come directly from customers; a secretary who runs the office; and a General Manager who oversees the whole operation and reports to MegaCorp. Personnel practices have historically been pretty informal around SRP, but there is now increasing pressure from the home office to tighten up practices relating to compensation. This is partly in response to some complaints from employees who felt unfairly treated (leading to turnover in what had been a very tightly knit workforce), and partly in response to the growth that had led MegaCorz to develop a more sophisticated approach to HR. Each of your teams represents a consultant team charged with developing an internally consistent compensation system that will be perceived as fair and that will help position SRP to meet its strategic goals. (Apparently an unusually large consulting budget was developed this year!) The existing job descriptions appear in the pages that follow. However, since they were developed on an ad hoc basis over a period of time, you are welcome to consult the web or other sources for more information about the jobs if you find that useful. Title: General Manager General Summary: The General Manager is responsible for all phases of the SRP operation. This includes financial oversight, approval of product development direction, supervisory responsibility for all employees, and supervision of day-to-day operations. Reports to Vice President of Operations at MegaCorp. Principal Duties and Responsibilities: - Oversees setup of production area - Sets work and production schedules and monitors productivity of all operations - Review and analyze daily production results and determines efficiency and quality ratings - Responsible for maintaining a safe and efficient work environment - Reviews and approves any changes to product line - Reviews and approves requisition requests for items over $250 - Primary liaison with vendors, also coordinates with customers as needed - Handles questions, conflicts or other problems - Responsible for all personnel decisions (hiring, performance reviews, firing) - Provides or coordinates on-the-job training, as appropriate - Supports and assists machine operators in maintenance and repair requirements Knowledge,SkillsandAbilitiesRequired: - Strong technical background in manufacturing and auto racing technology - Strong project management skills - Ability to coordinate sales and production team members - Good financial accounting skills - Ability to problem solve Education and Training Requirements - Bachelor's degree in Business required, MBA preferred.| - 3 years prior managerial experience Working Conditions Normal office environment (normal temperature, humidity and noise) for 5060% of work time 2530% of time spent in shop environment working with machine operators, with remaining tir working with customers or management at MegaCorp. Typically 23 days travel/month requi: Title: Drafter General Summary: Prepares product engineering drawings of easily visualized parts or equipment from sketches or marked-up prints. Work requires use of most conventional drafting procedures, including some Computer-Aided Design (CAD) technology. Works closely with sales representatives and customers for input into product design, and with machine operators for development of final product design. Principal Duties and Responsibilities: - Prepares product engineering designs of braking and suspension components from sketches, marked up prints, or existing prototypes. Selects appropriate templates and other equipment needed to complete assignments. - Uses both manual (tracing, technical drawing) and CAD workstation equipment to prepare detailed drawings describing arrangements, dimensions and tolerances. - Assembles and writes parts lists - Operates copying, digital printing, and digital plotters to produce drawings and technical specifications - Use mathematical formulas to check dimensions, tolerances and the like. - Requisitions and maintains an adequate supply of materials needed to complete work. - Operates with high degree of discretion and responsibility Knowledge, Skills and Abilities Required: - Ability to read, comprehend and follow complicated verbal and written instructions - Ability to perform basic arithmetic, geometric and algebraic calculations - Basic skill in using CAD programs on high-end workstation (details can be learned on the job) - Knowledge of most conventional drafting techniques, including the proper use of engineering/drafting terminology, symbols, legends and shading - normally acquired in 6 months of basic technical training and/or in high school - Ability to meet deadlines, concentrate, and pay attention to detail for 75% of work time. - Standing and walking required for less than 10% of work time. - Familiarity with and interest in auto racing desirable Education and Training Requirements - High school/GED required; BS in technical area desirable - Advanced training in technical/drafting or 3 years experience Working Conditions Title: Field Sales Representative General Summary: Maintains and expands existing accounts by working closely with customers to provide quality customer service and product information. Creates new accounts through contact at racing events and recommendations by current customers. Works closely with customers to understand evolving needs and with drafters/machine operators to develop products (and enhancements) to meet those needs. Principal Duties and Responsibilities: - Maintain and expand existing accounts through continuous follow-ups and interaction - Cultivate new accounts by soliciting referrals from current customers and by meeting potential new customers at races and other events. - Confirms eligibility and creditworthiness of new and existing accounts - Provides field support of products to customers. - Troubleshoots any problems with equipment specifications, delivery, or functionality by working as liaison between customers and Internal Sales Representatives - Seeks ideas and suggestions for new product enhancements by working closely with customers and by monitoring competitors - Maintains own knowledge of products, sales techniques and market trends Knowledge,SkillsandAbilitiesRequired: - Basic technical understanding of racing products/technology - Ability to clearly communicate technical information to and from buyers and product designers - Ability to relate to race drivers and crew chiefs - Excellent customer service skills - Strong sales orientationskill in meeting people, making effective sales presentations, closing the sale, and providing effective follow-up - Strong work ethic and sense of integrity - Ability to work independently and stay goal-oriented Education and Training Requirements - High school diploma/GED required; college degree (preferably in Business) desirable - At least two years technical sales experience - Sales training desirable Working Conditions Extensive time traveling ( 3 weeks/month) to races, product shows, race teams. Much of the time spent with customers may be in noisy, hot, sometimes dangerous work environments. Title: CNC Machinist/Operator General Summary: Responsible for the efficient operation of one or more assigned CNC machine tools to produce component parts in accordance to customer drawings, internal sketches, or other specifications provided by drafter. PrincipalDutiesandResponsibilities: - Responsible for scheduling of appropriate jobs in order to meet production goals - Using product engineering drawings and specifications, programs, sets up, and operates CNC equipment to produce high-precision suspension and brake components. - Performs follow-up operations, such as deburring, polishing, grinding, threading. - Performs and documents in-process QA inspections - Performs regular maintenance. As necessary and able, performs repair on equipment. - Works closely with drafter to ensure that product design meets technical and customer standards. - Works with Internal Sales reps to maintain product inventory control system. - Requisitions and maintains an adequate supply of materials needed to complete work. Knowledge, Skills and Abilities Required: - Ability to read, comprehend and follow complicated verbal and written instructions - Ability to perform basic arithmetic, geometric and algebraic calculations - Proficiency in CNC machine programming - Skill in use of conventional measuring tools and techniques, to assure compliance with technical specifications. - Working knowledge of all basic machine shop tools and equipment - Ability to meet deadlines, concentrate, and pay attention to detail for 75% of work time. - Strong safety orientation. - Standing and walking required for 90% of work time. Ability to lift, carry and hold up to 50 pounds. Education and Training Requirements - High school/GED and 3 years experience, or advanced CNC training and 2 years experience, or Bachelor's degree in Tool Manufacturing and one year experience. Working Conditions Machine shop working environment, with high noise levels and some variability in temperature and humidity. Dust, grease and metal shavings common. Significant safety risks from equipment and environment require constant vigilance and care. Overtime may be required during peak business periods and to meet rush requirements. JOB EVALUATION FORM Weightage Criteria (Total points in Job Evaluation plan= 1000) Job Evaluation-GM Job Evaluation- Drafter Job Evaluation-Field Sales Rep Job Evaluation-CNC Machinist/Operator Background Specialized Racing Products (SRP) is a relatively small operation in Englewood, Colorado dedicated to providing the highest quality specialty products to sprint car racing teams throughout the US (as well as internationally via mail and internet orders). SRP is a subsidiary of a larger manufacturing organization, which we will call MegaCorp. It was created by a group of employees who were themselves race enthusiasts or former racers/crews who saw a need that they could fulfill. SRP's mission is to provide specialized suspension and brake system components that are purposebuilt for sprint car racing, are of higher quality than those available from larger manufacturers, and are nonetheless price competitive. (Note, however, that in the world of auto racing, nothing is "cheap"!) SRP provides itself on understanding racers' evolving needs and being able to provide customized solutions with a faster turnaround than their larger, more bureaucratic competitors. Their workforce consists of three skilled machinists who use sophisticated computer-based CNC milling machines to produce a fairly small volume of components; two drafters to develop plans and specifications for the parts; two external sales reps who mostly sell directly to race teams; two internal sales reps who process orders from the external sales reps as well as orders that come directly from customers; a secretary who runs the office; and a General Manager who oversees the whole operation and reports to MegaCorp. Personnel practices have historically been pretty informal around SRP, but there is now increasing pressure from the home office to tighten up practices relating to compensation. This is partly in response to some complaints from employees who felt unfairly treated (leading to turnover in what had been a very tightly knit workforce), and partly in response to the growth that had led MegaCorz to develop a more sophisticated approach to HR. Each of your teams represents a consultant team charged with developing an internally consistent compensation system that will be perceived as fair and that will help position SRP to meet its strategic goals. (Apparently an unusually large consulting budget was developed this year!) The existing job descriptions appear in the pages that follow. However, since they were developed on an ad hoc basis over a period of time, you are welcome to consult the web or other sources for more information about the jobs if you find that useful. FACTOR 1 - KNOWLEDGE REQUIRED BY THE POSITION Factor 1 measures the nature and extent of information or facts that employees must understand to do acceptable work (e.g., steps, procedures, practices, rules, policies, theories, principles, and concepts) and the nature and extent of the skills needed to apply those knowledge. To be used as a basis for selecting a level under this factor, a knowledge must be required and applied. Level 1-1 Knowledge of simple, routine, or repetitive tasks or operations which typically includes | following step-by-step instructions and requires little or no previous training or experience; OR Skill to operate simple equipment or equipment that operates repetitively, requiring little or no previous training or experience; OR Equivalent knowledge and skill. Level 1-2 Knowledge of basic or commonly-used rules, procedures, or operations that typically requires some previous training or experience; OR Basic skill to operate equipment requiring some previous training or experience, such as keyboard equipment; OR Equivalent knowledge and skill. Level 1-3 Knowledge of a body of standardized rules, procedures or operations requiring considerable training and experience to perform the full range of standard clerical assignments and resolve recurring problems; OR Skill, acquired through considerable training and experience, to operate and adjust varied equipment for purposes such as performing numerous standardized tests or operations; OR Equivalent knowledge and skill. Level 1-4 Knowledge of an extensive body of rules, procedures or operations requiring extended training and experience to perform a wide variety of interrelated or nonstandard procedural assignments and resolve a wide range of problems; OR Practical knowledge of standard procedures in a technical field, requiring extended training or experience, to perform such work as adapting equipment when this requires considering the functioning characteristics of equipment; interpreting results of tests based on previous experience and observations (rather than directly reading instruments or other measures); or extracting information from various sources when this requires considering the applicability of information and the characteristics and quality of the sources; OR Knowledge (such as would be acquired through a pertinent baccalaureate educational program or its equivalent in experience, training, or independent study) of basic principles, concepts, and methodology of a professional or administrative occupation, and skill in applying this knowledge in carrying out elementary assignments, operations, or procedures; OR In addition to the practical knowledge of standard procedures in Level 1-4, practical knowledge of technical methods to perform assignments such as carrying out limited projects which involves use of specialized, complicated techniques; OR Equivalent knowledge and skill. Level 1-6 Knowledge of the principles, concepts, and methodology of a professional or administrative occupation as described at Level 1-5 which has been either: (a) supplemented by skill gained through job experience to permit independent performance of recurring assignments, or (b) supplemented by expanded professional or administrative knowledge gained through relevant graduate study or experience, in carrying out assignments, operations, and procedures in the occupation which are significantly more difficult and complex than those covered by Level 1-5; OR Practical knowledge of a wide range of technical methods, principles, and practices similar to a narrow area of a professional field, and skill in applying this knowledge to such assignments as the design and planning of difficult, but well-precedented projects; Equivalent knowledge and skill. Level 1-7 Knowledge of a wide range of concepts, principles, and practices in a professional or administrative occupation, such as would be gained through extended graduate study or experience, and skill in applying this knowledge to difficult and complex work assignments; OR A comprehensive, intensive, practical knowledge of a technical field and skill in applying this knowledge to the development of new methods, approaches, or procedures; OR Equivalent knowledge and skill. FACTOR 2 - COMPLEXITY This factor covers the nature, number, variety, and intricacy of tasks, steps, processes, or methods in the work performed; the difficulty in identifying what needs to be done; and the difficulty and originality involved in performing the work. Level 2-1 The work consists of tasks that are clear-cut and directly related. There is little or no choice to be made in deciding what needs to be done. Actions to be taken or responses to be made are readily discernible. The work is quickly mastered. Level 2-2 The work consists of duties that involve related steps, processes, or methods. The decision regarding what needs to be done involves various choices requiring the employee to recognize the existence of and differences among a few easily recognizable situations. Actions to be taken or responses to be made differ in such things as the source of information, the kind of transactions or entries, or other differences of a factual nature. Level 2-3 The work includes various duties involving different and unrelated processes and methods. The decision regarding what needs to be done depends upon the analysis of the subject, phase, or issues involved in each assignment, and the chosen course of action may have to be selected from many alternatives. The work involves conditions and elements that must be identified and analyzed to discern interrelationships. Level 2-4 The work typically includes varied duties requiring many different and unrelated processes and methods such as those relating to well-established aspects of an administrative or professional field. Decisions regarding what needs to be done include the assessment of unusual circumstances, variations in approach, and incomplete or conflicting data. The work requires making many decisions concerning such things as the interpreting of considerable data, planning of the work, or refining the methods and techniques to be used. Scope and Effect covers the relationship between the nature of the work, i.e., the purpose, breadth, and depth of the assignment, and the effect of work products or services both within and outside the organization. Effect measures such things as whether the work output facilitates the work of others, provides timely services of a personal nature, or impacts on the adequacy of research conclusions. The concept of effect alone does not provide sufficient information to properly understand and evaluate the impact of the position. The scope of the work completes the picture, allowing consistent evaluations. Only the effect of properly performed work is to be considered. Level 3-1 The work involves the performance of specific, routine operations that include a few separate tasks or procedures. The work product or service is required to facilitate the work of others; however, it has little impact beyond the immediate organizational unit or beyond the timely provision of limited services to others. Level 3-2 The work involves the execution of specific rules, regulations, or procedures and typically comprises a complete segment of an assignment or project of broader scope. The work product or service affects the accuracy, reliability, or acceptability of further processes or services. Level 3-3 The work involves treating a variety of conventional problems, questions, or situations in conformance with established criteria. The work product or service affects the design or operation of systems, programs, or equipment; the adequacy of such activities as field investigations, testing operations, or research conclusions; or the social, physical, and economic well-being of persons. Level 3-4 The work involves establishing criteria; formulating projects; assessing program effectiveness; or investigating or analyzing a variety of unusual conditions, problems, or questions. The work product or service affects a wide range of agency activities, major activities of industrial concerns, or the operation of other agencies. FACTOR 4 - PHYSICAL DEMANDS The "Physical Demands" factor covers the requirements and physical demands placed on the employee by the work assignment. This includes physical characteristics and abilities (e.g., specific agility and dexterity requirements) and the physical exertion involved in the work (e.g., climbing, lifting, pushing, balancing, stooping, kneeling, crouching, crawling, or reaching). To some extent the frequency or intensity of physical exertion must also be considered, e.g., a job requiring prolonged standing involves more physical exertion than a job requiring intermittent standing. Background Specialized Racing Products (SRP) is a relatively small operation in Englewood, Colorado dedicated to providing the highest quality specialty products to sprint car racing teams throughout the US (as well as internationally via mail and internet orders). SRP is a subsidiary of a larger manufacturing organization, which we will call MegaCorp. It was created by a group of employees who were themselves race enthusiasts or former racers/crews who saw a need that they could fulfill. SRP's mission is to provide specialized suspension and brake system components that are purposebuilt for sprint car racing, are of higher quality than those available from larger manufacturers, and are nonetheless price competitive. (Note, however, that in the world of auto racing, nothing is "cheap"!) SRP provides itself on understanding racers' evolving needs and being able to provide customized solutions with a faster turnaround than their larger, more bureaucratic competitors. Their workforce consists of three skilled machinists who use sophisticated computer-based CNC milling machines to produce a fairly small volume of components; two drafters to develop plans and specifications for the parts; two external sales reps who mostly sell directly to race teams; two internal sales reps who process orders from the external sales reps as well as orders that come directly from customers; a secretary who runs the office; and a General Manager who oversees the whole operation and reports to MegaCorp. Personnel practices have historically been pretty informal around SRP, but there is now increasing pressure from the home office to tighten up practices relating to compensation. This is partly in response to some complaints from employees who felt unfairly treated (leading to turnover in what had been a very tightly knit workforce), and partly in response to the growth that had led MegaCorz to develop a more sophisticated approach to HR. Each of your teams represents a consultant team charged with developing an internally consistent compensation system that will be perceived as fair and that will help position SRP to meet its strategic goals. (Apparently an unusually large consulting budget was developed this year!) The existing job descriptions appear in the pages that follow. However, since they were developed on an ad hoc basis over a period of time, you are welcome to consult the web or other sources for more information about the jobs if you find that useful. Title: General Manager General Summary: The General Manager is responsible for all phases of the SRP operation. This includes financial oversight, approval of product development direction, supervisory responsibility for all employees, and supervision of day-to-day operations. Reports to Vice President of Operations at MegaCorp. Principal Duties and Responsibilities: - Oversees setup of production area - Sets work and production schedules and monitors productivity of all operations - Review and analyze daily production results and determines efficiency and quality ratings - Responsible for maintaining a safe and efficient work environment - Reviews and approves any changes to product line - Reviews and approves requisition requests for items over $250 - Primary liaison with vendors, also coordinates with customers as needed - Handles questions, conflicts or other problems - Responsible for all personnel decisions (hiring, performance reviews, firing) - Provides or coordinates on-the-job training, as appropriate - Supports and assists machine operators in maintenance and repair requirements Knowledge,SkillsandAbilitiesRequired: - Strong technical background in manufacturing and auto racing technology - Strong project management skills - Ability to coordinate sales and production team members - Good financial accounting skills - Ability to problem solve Education and Training Requirements - Bachelor's degree in Business required, MBA preferred.| - 3 years prior managerial experience Working Conditions Normal office environment (normal temperature, humidity and noise) for 5060% of work time 2530% of time spent in shop environment working with machine operators, with remaining tir working with customers or management at MegaCorp. Typically 23 days travel/month requi: Title: Drafter General Summary: Prepares product engineering drawings of easily visualized parts or equipment from sketches or marked-up prints. Work requires use of most conventional drafting procedures, including some Computer-Aided Design (CAD) technology. Works closely with sales representatives and customers for input into product design, and with machine operators for development of final product design. Principal Duties and Responsibilities: - Prepares product engineering designs of braking and suspension components from sketches, marked up prints, or existing prototypes. Selects appropriate templates and other equipment needed to complete assignments. - Uses both manual (tracing, technical drawing) and CAD workstation equipment to prepare detailed drawings describing arrangements, dimensions and tolerances. - Assembles and writes parts lists - Operates copying, digital printing, and digital plotters to produce drawings and technical specifications - Use mathematical formulas to check dimensions, tolerances and the like. - Requisitions and maintains an adequate supply of materials needed to complete work. - Operates with high degree of discretion and responsibility Knowledge, Skills and Abilities Required: - Ability to read, comprehend and follow complicated verbal and written instructions - Ability to perform basic arithmetic, geometric and algebraic calculations - Basic skill in using CAD programs on high-end workstation (details can be learned on the job) - Knowledge of most conventional drafting techniques, including the proper use of engineering/drafting terminology, symbols, legends and shading - normally acquired in 6 months of basic technical training and/or in high school - Ability to meet deadlines, concentrate, and pay attention to detail for 75% of work time. - Standing and walking required for less than 10% of work time. - Familiarity with and interest in auto racing desirable Education and Training Requirements - High school/GED required; BS in technical area desirable - Advanced training in technical/drafting or 3 years experience Working Conditions Title: Field Sales Representative General Summary: Maintains and expands existing accounts by working closely with customers to provide quality customer service and product information. Creates new accounts through contact at racing events and recommendations by current customers. Works closely with customers to understand evolving needs and with drafters/machine operators to develop products (and enhancements) to meet those needs. Principal Duties and Responsibilities: - Maintain and expand existing accounts through continuous follow-ups and interaction - Cultivate new accounts by soliciting referrals from current customers and by meeting potential new customers at races and other events. - Confirms eligibility and creditworthiness of new and existing accounts - Provides field support of products to customers. - Troubleshoots any problems with equipment specifications, delivery, or functionality by working as liaison between customers and Internal Sales Representatives - Seeks ideas and suggestions for new product enhancements by working closely with customers and by monitoring competitors - Maintains own knowledge of products, sales techniques and market trends Knowledge,SkillsandAbilitiesRequired: - Basic technical understanding of racing products/technology - Ability to clearly communicate technical information to and from buyers and product designers - Ability to relate to race drivers and crew chiefs - Excellent customer service skills - Strong sales orientationskill in meeting people, making effective sales presentations, closing the sale, and providing effective follow-up - Strong work ethic and sense of integrity - Ability to work independently and stay goal-oriented Education and Training Requirements - High school diploma/GED required; college degree (preferably in Business) desirable - At least two years technical sales experience - Sales training desirable Working Conditions Extensive time traveling ( 3 weeks/month) to races, product shows, race teams. Much of the time spent with customers may be in noisy, hot, sometimes dangerous work environments. Title: CNC Machinist/Operator General Summary: Responsible for the efficient operation of one or more assigned CNC machine tools to produce component parts in accordance to customer drawings, internal sketches, or other specifications provided by drafter. PrincipalDutiesandResponsibilities: - Responsible for scheduling of appropriate jobs in order to meet production goals - Using product engineering drawings and specifications, programs, sets up, and operates CNC equipment to produce high-precision suspension and brake components. - Performs follow-up operations, such as deburring, polishing, grinding, threading. - Performs and documents in-process QA inspections - Performs regular maintenance. As necessary and able, performs repair on equipment. - Works closely with drafter to ensure that product design meets technical and customer standards. - Works with Internal Sales reps to maintain product inventory control system. - Requisitions and maintains an adequate supply of materials needed to complete work. Knowledge, Skills and Abilities Required: - Ability to read, comprehend and follow complicated verbal and written instructions - Ability to perform basic arithmetic, geometric and algebraic calculations - Proficiency in CNC machine programming - Skill in use of conventional measuring tools and techniques, to assure compliance with technical specifications. - Working knowledge of all basic machine shop tools and equipment - Ability to meet deadlines, concentrate, and pay attention to detail for 75% of work time. - Strong safety orientation. - Standing and walking required for 90% of work time. Ability to lift, carry and hold up to 50 pounds. Education and Training Requirements - High school/GED and 3 years experience, or advanced CNC training and 2 years experience, or Bachelor's degree in Tool Manufacturing and one year experience. Working Conditions Machine shop working environment, with high noise levels and some variability in temperature and humidity. Dust, grease and metal shavings common. Significant safety risks from equipment and environment require constant vigilance and care. Overtime may be required during peak business periods and to meet rush requirements. JOB EVALUATION FORM Weightage Criteria (Total points in Job Evaluation plan= 1000) Job Evaluation-GM Job Evaluation- Drafter Job Evaluation-Field Sales Rep Job Evaluation-CNC Machinist/Operator

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock