Question: Question 1 : Labour Productivity A company is considering two locations for manufacturing its products: Location X and Location Y . The labour costs and

Question : Labour Productivity

A company is considering two locations for manufacturing its products: Location X and Location Y The labour costs and production capacities at each location differ. Below are the details for each location:

Location X:

Labour cost per day: $

Hours required per unit:

Maximum production capacity: units per month Location Y:

Labour cost per hour: $

Hours required per unit:

Maximum production capacity: units per month

Question

Calculate the labour cost per unit for each location.

Question

Note: this answer does not require a calculation but an analysis of the information.

If the company plans to produce units per month, which location should they choose based on labour cost per unit?

Question

Note: this answer does not require a calculation but an analysis of the information.

If the company plans to increase production to units per month, which location is the better option considering both labour costs per unit and productivity capacity?

A ocal emtrepreneur wants to upenn a volne manuracturng piant with a warehouse in Prince Edward County to supply the warehouses in the county most efficiently. Using the centre of gravity method, where should this manufacturerwarehouse be located?

tableXYProjected # of Cases of Bottlesper monthVineyardsThree Dog Winery,Waupoos Estates Winery,Black Prince Winery,Huff Estate Winery,TerraCello Winery,Karlo Estates,Sandbanks Winery,CasaDea Winery,Traynor Family Vinyard,Closson Chase Vineyards

Calculate the X and Y coordinates to decimal place.

Question : Staffing & Balancing Work Cells

A manufacturing facility produces units of a product in an hour shift. The total available time for production in hours when accounting for breaks. If the total cycle time to produce one unit is minutes, calculate the takttime and then determine the number of workers needed to staff the work cell to meet the production demand.

Question Takt Time

Calculate takttime in seconds per unit

Question Workers Needed

Calculate the number of workers needed in the work cell.

Question : Time Studies

A time study was conducted on a particular task performed by an operator in a manufacturing plant. The allowance factor is The following times, in seconds, were recorded for ten cycles of the task:

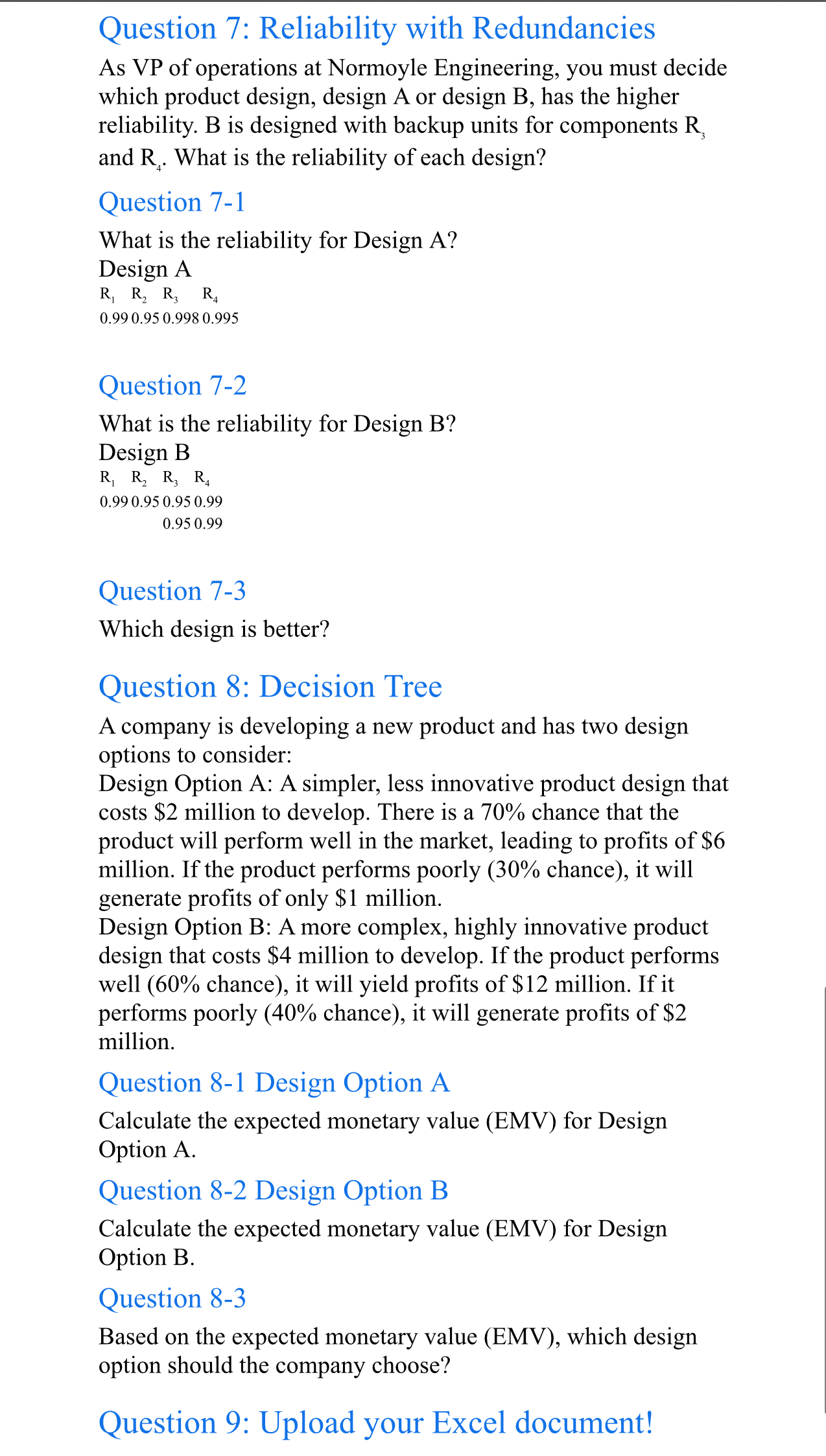

Question : Reliability with Redundancies

As VP of operations at Normoyle Engineering, you must decide which product design, design A or design B has the higher reliability. B is designed with backup units for components and What is the reliability of each design?

Question

What is the reliability for Design A

Design A

Question

What is the reliability for Design B

Design

Question

Which design is better?

Question : Decision Tree

A company is developing a new product and has two design options to consider:

Design Option A: A simpler, less innovative product design that costs $ million to develop. There is a chance that the product will perform well in the market, leading to profits of $ million. If the product performs poorly chance it will generate profits of only $ million.

Design Option B: A more complex, highly innovative product design that costs $ million to develop. If the product performs well chance it will yield profits of $ million. If it performs poorly chance it will generate profits of $ million.

Question Design Option A

Calculate the expected monetary value EMV for Design Option A

Question Design Option B

Calculate the expected monetary value EMV for Design Option B

Question

Based on the expected monetary value EMV which design option should the company choose?

Question : Upload your Excel document!

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock