Question: Question 1 - Part I (15 points): ABC-Company is a major cell phone manufacturer to be established. The estimated market sizes of ABC are as

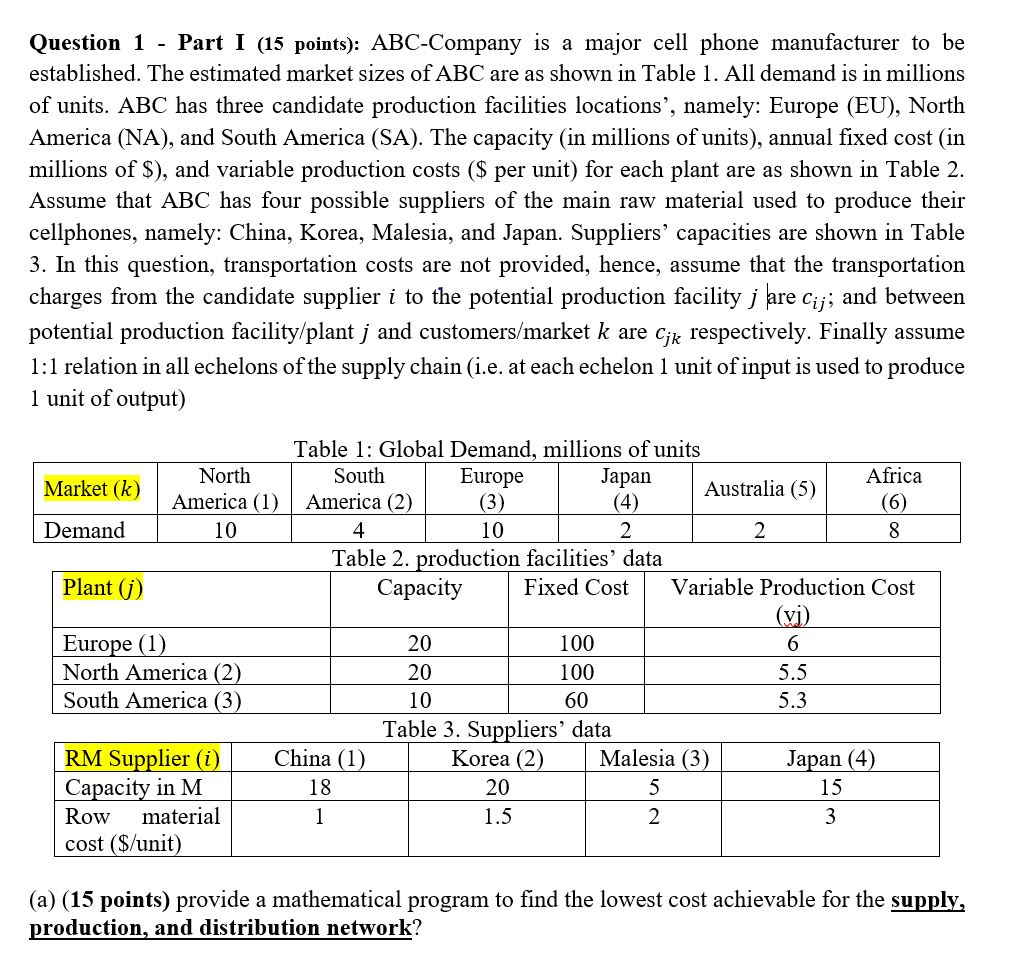

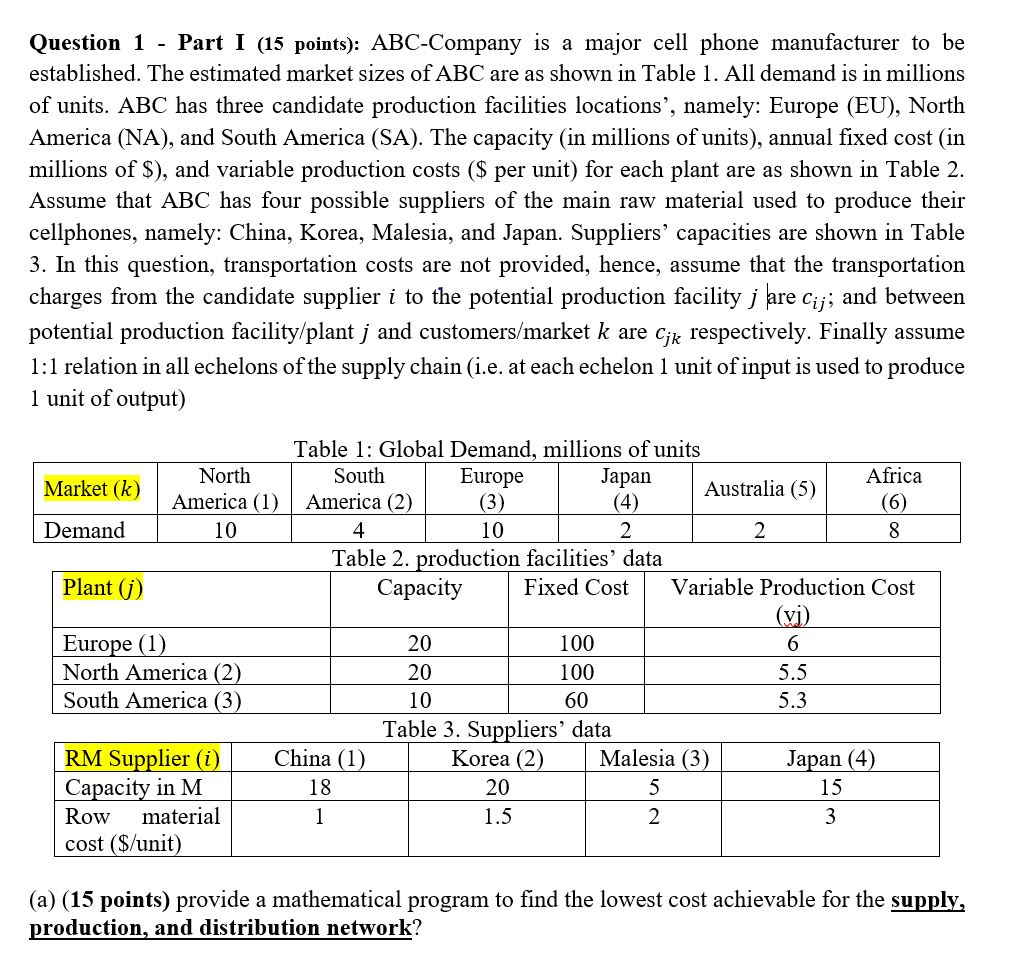

Question 1 - Part I (15 points): ABC-Company is a major cell phone manufacturer to be established. The estimated market sizes of ABC are as shown in Table 1. All demand is in millions of units. ABC has three candidate production facilities locations', namely: Europe (EU), North America (NA), and South America (SA). The capacity (in millions of units), annual fixed cost (in millions of $), and variable production costs ($ per unit) for each plant are as shown in Table 2. Assume that ABC has four possible suppliers of the main raw material used to produce their cellphones, namely: China, Korea, Malesia, and Japan. Suppliers' capacities are shown in Table 3. In this question, transportation costs are not provided, hence, assume that the transportation charges from the candidate supplier i to the potential production facility j are Cij; and between potential production facility/plant j and customers/market k are Cik respectively. Finally assume 1:1 relation in all echelons of the supply chain (i.e. at each echelon 1 unit of input is used to produce 1 unit of output) Market (k) North America (1) 10 Demand Table 1: Global Demand, millions of units South Europe Japan Africa Australia (5) America (2) (3) (4) (6) 4 / 10 / 2 28 Table 2. production facilities' data | Variable Production Cost Plant (1) (vi) Europe (1) North America (2) South America (3) 20 20 100 100 10 60 Table 3. Suppliers' data Korea (2) Malesia (3) 6 5.5 5.3 Japan (4) China (1) 18 20 15 RM Supplier (i) Capacity in M Row material cost ($/unit) 1.5 (a) (15 points) provide a mathematical program to find the lowest cost achievable for the supply production, and distribution network? Question 1 - Part I (15 points): ABC-Company is a major cell phone manufacturer to be established. The estimated market sizes of ABC are as shown in Table 1. All demand is in millions of units. ABC has three candidate production facilities locations', namely: Europe (EU), North America (NA), and South America (SA). The capacity (in millions of units), annual fixed cost (in millions of $), and variable production costs ($ per unit) for each plant are as shown in Table 2. Assume that ABC has four possible suppliers of the main raw material used to produce their cellphones, namely: China, Korea, Malesia, and Japan. Suppliers' capacities are shown in Table 3. In this question, transportation costs are not provided, hence, assume that the transportation charges from the candidate supplier i to the potential production facility j are Cij; and between potential production facility/plant j and customers/market k are Cik respectively. Finally assume 1:1 relation in all echelons of the supply chain (i.e. at each echelon 1 unit of input is used to produce 1 unit of output) Market (k) North America (1) 10 Demand Table 1: Global Demand, millions of units South Europe Japan Africa Australia (5) America (2) (3) (4) (6) 4 / 10 / 2 28 Table 2. production facilities' data | Variable Production Cost Plant (1) (vi) Europe (1) North America (2) South America (3) 20 20 100 100 10 60 Table 3. Suppliers' data Korea (2) Malesia (3) 6 5.5 5.3 Japan (4) China (1) 18 20 15 RM Supplier (i) Capacity in M Row material cost ($/unit) 1.5 (a) (15 points) provide a mathematical program to find the lowest cost achievable for the supply production, and distribution network