Question: Question #1 Question #2 Question #3 Formulate a chase sales and operations plan for a company with the following predicted demand: 6 Month Demand 1

Question #1

Question #2

Question #3

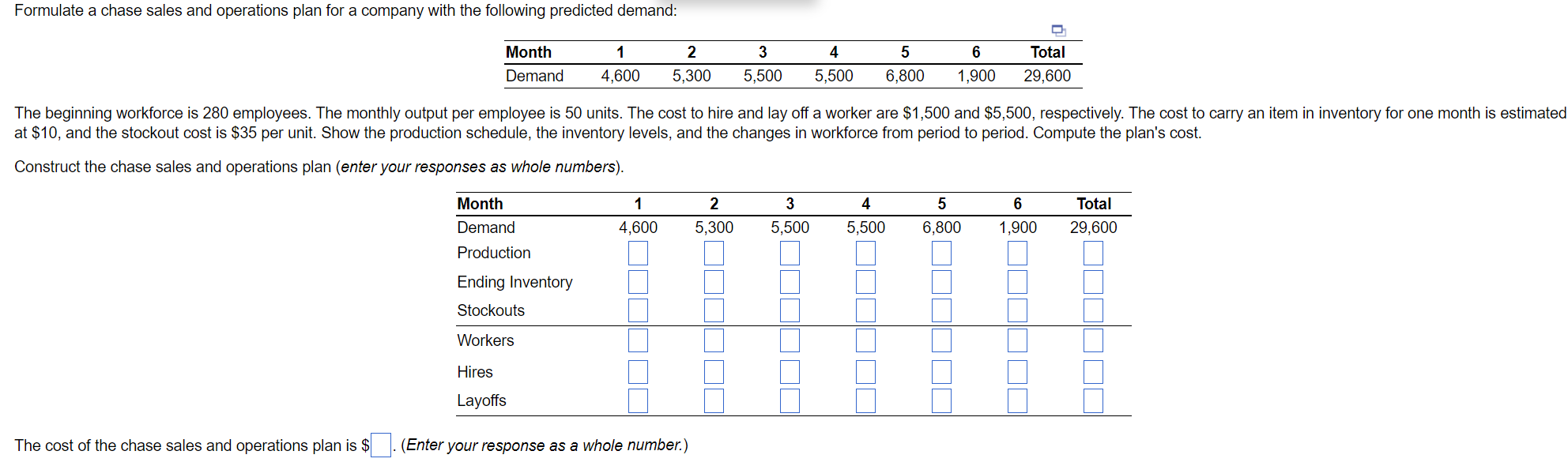

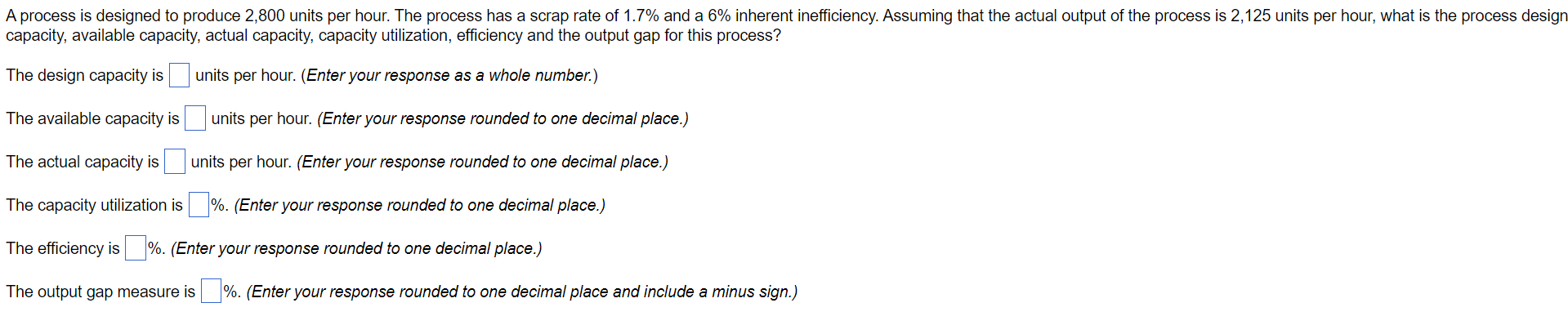

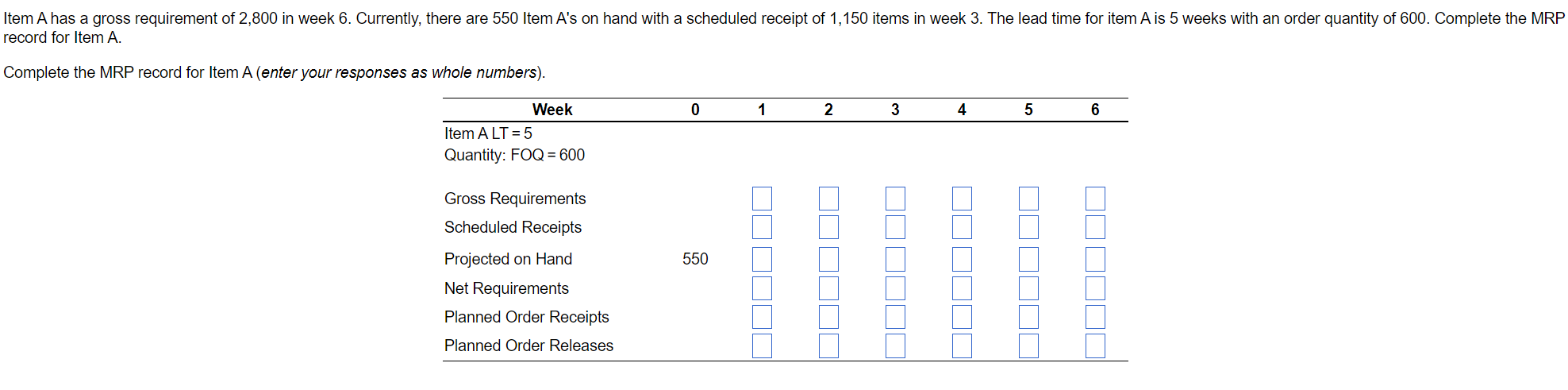

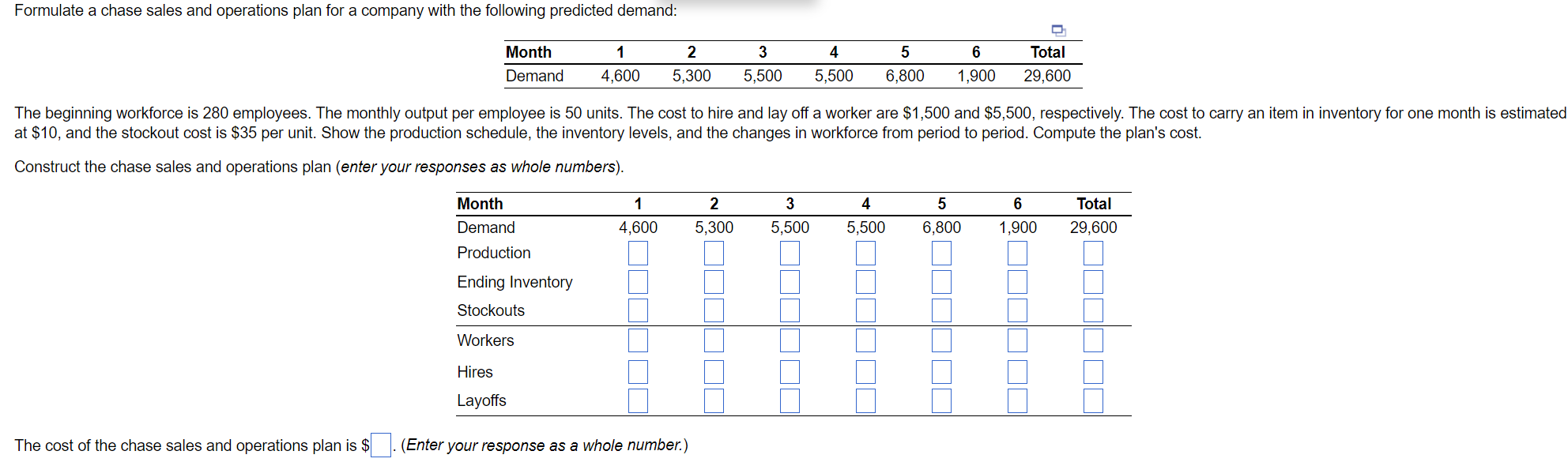

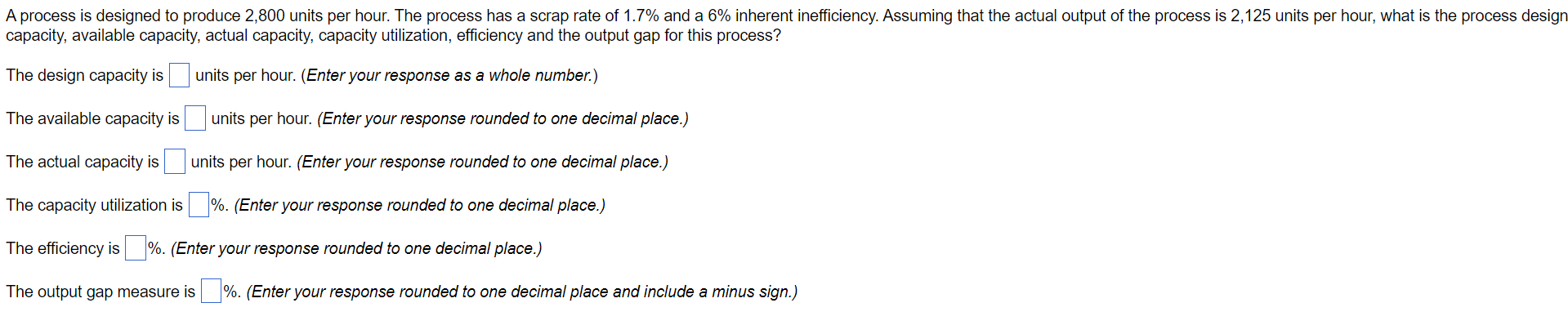

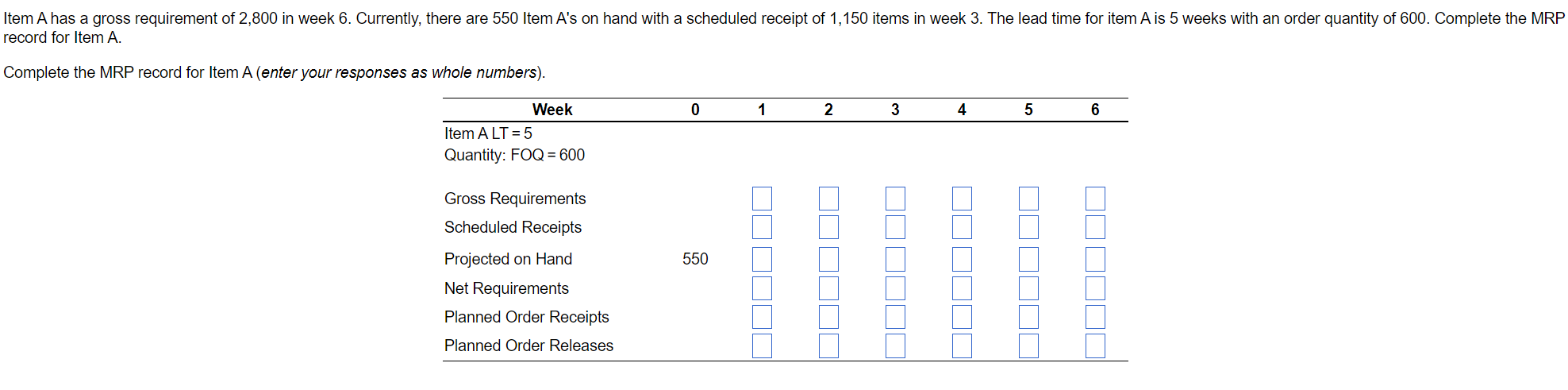

Formulate a chase sales and operations plan for a company with the following predicted demand: 6 Month Demand 1 4,600 2 5,300 3 5,500 4 5,500 5 6,800 Total 29,600 1,900 The beginning workforce is 280 employees. The monthly output per employee is 50 units. The cost to hire and lay off a worker are $1,500 and $5,500, respectively. The cost to carry an item in inventory for one month is estimated at $10, and the stockout cost is $35 per unit. Show the production schedule, the inventory levels, and the changes in workforce from period to period. Compute the plan's cost. Construct the chase sales and operations plan (enter your responses as whole numbers). 1 3 4 5 6 Month Demand Production 2 5,300 Total 29,600 4,600 5,500 5,500 6,800 1,900 Ending Inventory Stockouts Workers Hires Layoffs The cost of the chase sales and operations plan is $ (Enter your response as a whole number.) A process is designed to produce 2,800 units per hour. The process has a scrap rate of 1.7% and a 6% inherent inefficiency. Assuming that the actual output of the process is 2,125 units per hour, what is the process design capacity, available capacity, actual capacity, capacity utilization, efficiency and the output gap for this process? The design capacity is units per hour. (Enter your response as a whole number.) The available capacity is units per hour. (Enter your response rounded to one decimal place.) The actual capacity is units per hour. (Enter your response rounded to one decimal place.) The capacity utilization is %. (Enter your response rounded to one decimal place.) The efficiency is %. (Enter your response rounded to one decimal place.) %. The output gap measure is l%. (Enter your response rounded to one decimal place and include a minus sign.) Item A has a gross requirement of 2,800 in week 6. Currently, there are 550 Item A's on hand with a scheduled receipt of 1,150 items in week 3. The lead time for item A is 5 weeks with an order quantity of 600. Complete the MRP record for Item A. Complete the MRP record for Item A (enter your responses as whole numbers). 0 1 2 3 4 5 6 Week Item ALT = 5 Quantity: FOQ = 600 Gross Requirements Scheduled Receipts Projected on Hand 550 Net Requirements Planned Order Receipts Planned Order Releases