Question: QUESTION 1 Table 6.1 shows the orders for five different jobs received by a medical device manufacturer. The manufacturer is currently at day 150 of

QUESTION 1

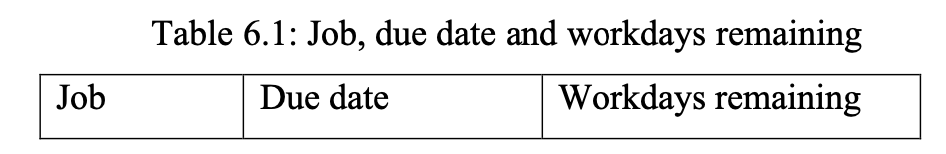

Table 6.1 shows the orders for five different jobs received by a medical device manufacturer. The manufacturer is currently at day 150 of its production schedule, and due to the current labour constraints, the manufacturer needs to reschedule the jobs in the best possible way. Determine the best sequence for the jobs by using critical ratio.

QUESTION 2

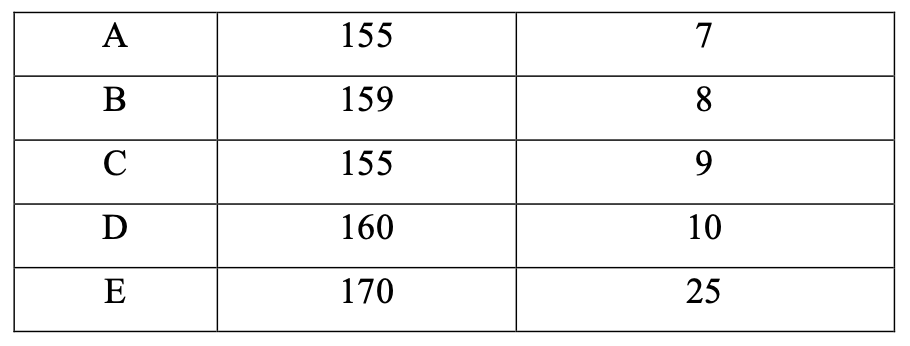

Antara Co, a metal fabrication company, has four fabrication jobs that can be carried out by four different machines. Table 6.2 shows the costs (in RM) of performing the fabrication jobs at different machines. Determine the assignment of fabrication jobs to machines that will minimise the total cost.

QUESTION 3

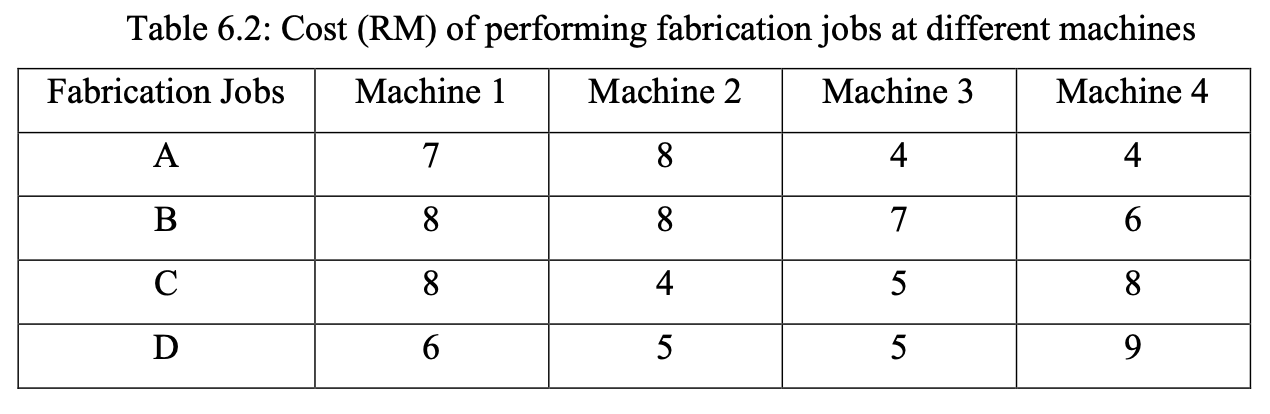

BAC Co wants to develop the best job schedule for its coming production of five units of micro motors. The micro motors model A-1, B-2, C-3, D-4 and E-5 have to go through two lengthy sequential machines; i.e. machine M followed by machine S. The times taken by each model at different machines are shown in Table 6.3.

a) Develop a job schedule for these five units of micro motor that minimizes the total completion time.

b) Supposed both machines run continuously 24 hours, 7 days a week. How much is the waiting time for micro motor model E-5 before it can be processed by machine S.

Table 6.1: Job, due date and workdays remaining Due date Workdays remaining Job A 155 7 B 159 8 155 9 D 160 10 E 170 25 Table 6.2: Cost (RM) of performing fabrication jobs at different machines Fabrication Jobs Machine 1 Machine 2 Machine 3 Machine 4 A 7 8 4 4 B 8 8 7 6 C 8 4 5 8 U A D 6 5 5 9 Table 6.3: Micro motor models and two sequential machines Micro motor models Quantity Machine M (hours) Machine S (hours) A-1 1 6 7 B-2 1 4 6 C-3 1 8 5 D-4 1 3 7 E-5 1 5 6Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts