Question: . Question 1) What is the average waiting time for a truck? I thought it was 4 Hrs based on the fact that the truck

.

.

Question 1) What is the average waiting time for a truck?

I thought it was 4 Hrs based on the fact that the truck arrived at 7 AM and the rest of the operation start at 11 AM but an F so this answer is wrong.

Knowing that bins are full, Trucks begin to wait from 10 am & Seasonal workers arrive at 10 am - Trucks stop waiting at 3 pm. Therefore, seasonal workers leave at 3 pm.

Question 2) How bad is the truck delay at the loading dock during peak season?

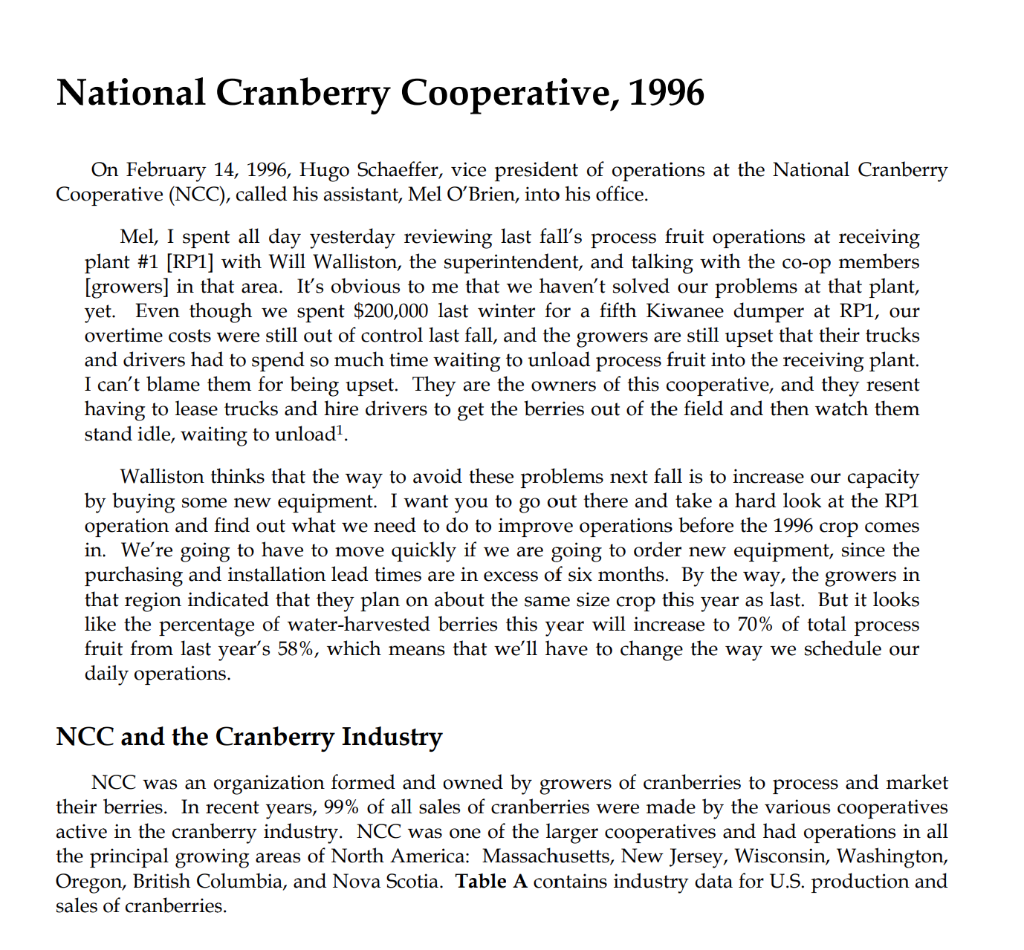

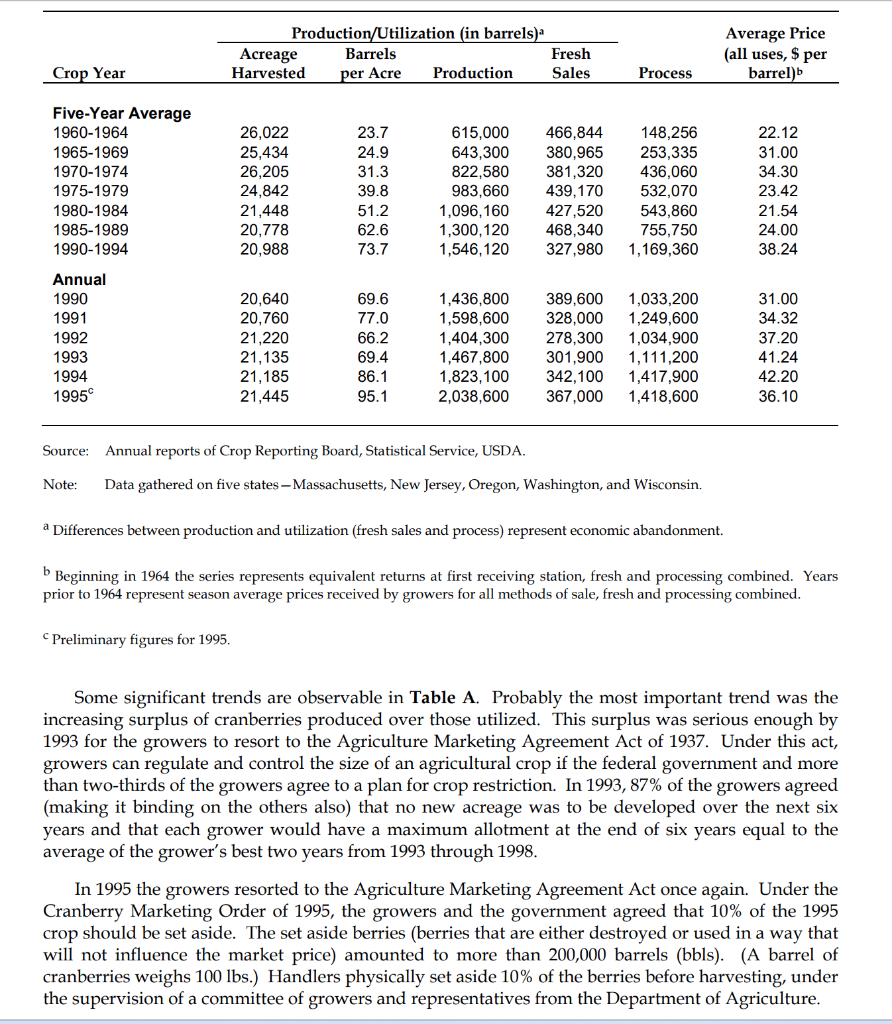

On February 14, 1996, Hugo Schaeffer, vice president of operations at the National Cranberry Cooperative (NCC), called his assistant, Mel O'Brien, into his office. Mel, I spent all day yesterday reviewing last fall's process fruit operations at receiving plant \#1 [RP1] with Will Walliston, the superintendent, and talking with the co-op members [growers] in that area. It's obvious to me that we haven't solved our problems at that plant, yet. Even though we spent $200,000 last winter for a fifth Kiwanee dumper at RP1, our overtime costs were still out of control last fall, and the growers are still upset that their trucks and drivers had to spend so much time waiting to unload process fruit into the receiving plant. I can't blame them for being upset. They are the owners of this cooperative, and they resent having to lease trucks and hire drivers to get the berries out of the field and then watch them stand idle, waiting to unload 1. Walliston thinks that the way to avoid these problems next fall is to increase our capacity by buying some new equipment. I want you to go out there and take a hard look at the RP1 operation and find out what we need to do to improve operations before the 1996 crop comes in. We're going to have to move quickly if we are going to order new equipment, since the purchasing and installation lead times are in excess of six months. By the way, the growers in that region indicated that they plan on about the same size crop this year as last. But it looks like the percentage of water-harvested berries this year will increase to 70% of total process fruit from last year's 58%, which means that we'll have to change the way we schedule our daily operations. NCC and the Cranberry Industry NCC was an organization formed and owned by growers of cranberries to process and market their berries. In recent years, 99% of all sales of cranberries were made by the various cooperatives active in the cranberry industry. NCC was one of the larger cooperatives and had operations in all the principal growing areas of North America: Massachusetts, New Jersey, Wisconsin, Washington, Oregon, British Columbia, and Nova Scotia. Table A contains industry data for U.S. production and sales of cranberries. Some significant trends are observable in Table A. Probably the most important trend was the increasing surplus of cranberries produced over those utilized. This surplus was serious enough by 1993 for the growers to resort to the Agriculture Marketing Agreement Act of 1937. Under this act, growers can regulate and control the size of an agricultural crop if the federal government and more than two-thirds of the growers agree to a plan for crop restriction. In 1993, 87\% of the growers agreed (making it binding on the others also) that no new acreage was to be developed over the next six years and that each grower would have a maximum allotment at the end of six years equal to the average of the grower's best two years from 1993 through 1998. In 1995 the growers resorted to the Agriculture Marketing Agreement Act once again. Under the Cranberry Marketing Order of 1995, the growers and the government agreed that 10% of the 1995 crop should be set aside. The set aside berries (berries that are either destroyed or used in a way that will not influence the market price) amounted to more than 200,000 barrels (bbls). (A barrel of cranberries weighs 100lbs.) Handlers physically set aside 10% of the berries before harvesting, under the supervision of a committee of growers and representatives from the Department of Agriculture. National Cranberry Cooperative, 1996 688122 Another important trend was the increasing mechanization of cranberry harvesting. Water harvesting, in particular, was developing rapidly in the vicinity of receiving plant No. 1. Under the traditional dry harvesting, berries were hand-picked from the bushes. In water harvesting, the bogs were flooded, the berries were mechanically shaken from the bushes, and the berries then were collected easily since they floated to the surface of the water. Water harvesting could result in yields up to 20% greater than those obtained via dry harvesting, but it caused some damage and it shortened the time that harvested fruit could be held prior to either its use or freezing for long-term storage. Water harvesting had developed at a remarkable rate in some areas. Receiving plant No. 1 received 25,000 bbls. of water-harvested fruit in 1993, 125,000 bbls. in 1994, and 350,000 bbls. in 1995. Receiving Plant No. 1 (RP1) RP1 received both "fresh" fruit and "process" fruit during a season that usually started early in September and was effectively finished by early December (see Figure A). The fresh fruit operation (preparing cranberries for sale as whole fresh fruit) was completely separate from the process fruit operation (that prepares cranberries for juice, canning, freezing, and other process fruit products) and took the fruit from receiving through packaging. This case is concerned only with the process fruit operation. Figure A Daily Delivery of Both Fresh and Process Berries to RP1 The handling of process fruit at RP1 was highly mechanized. The process could be classified into several operations: receiving and testing, dumping, temporary holding, destoning, 2 dechaffing 33 drying, separation, and bulking and bagging. The objective of the total process was to gather bulk berries and prepare them for storage and processing into frozen fresh berries, sauce, and juice. Process Fruit Receiving Bulk trucks carrying process berries arrived at RP1 randomly throughout the day as shown in Exhibit 1. The average truck delivery was 75 bbls. When the trucks arrived at RP1 they were weighed, and the gross weight and the tare (empty) weight were recorded. Prior to unloading, a sample of about 30lbs. of fruit (0.3bbl.) was taken from the truck. Later, this sample would be run through a small version of the cleaning and drying process used in the plant. By comparing the before and after weight of this sample, it was possible to estimate the percentage of the truck's net weight made up of clean, dry berries. At the same time, another sample was taken to determine the percentage of unusable berries (poor, smaller, and frosted berries) in the truck. The grower was credited for the estimated weight of the clean, dry, usable berries. (See Exhibit 2 for total 1995 deliveries of process berries.) At the time the truck was weighed, the truckload of berries was graded according to color. Using color pictures as a guide, the chief berry receiver classified the berries as Nos. 1, 2A, 2B, or 3, from poorest color (No. 1) to best (No. 3). There was a premium of $1.50 per bbl. paid for No. 3 berries, since color was considered to be a very important attribute of both juice products and whole sauce. Whenever there was any question about whether or not a truckload was No. 2B or No. 3 berries, the chief berry receiver usually chose No. 3. In 1995 the $1.50 premium was paid on about 450,000 bbls. of berries. When these berries were used, however, it was found that only about half of them were No. 3's. To improve this yield, Schaeffer was considering the installation of a light meter system for color grading. This system was projected to cost $40,000 and would require a full-time skilled operator at the same pay grade as the chief berry receiver. Temporary Holding After a truckload of process berries had been weighed, sampled, and color graded, the truck moved to one of the five Kiwanee dumpers. The truck was backed onto the dumper platform which then tilted until the contents of the truck dumped onto one of five rapidly moving belt conveyors. Each of the five conveyors took the berries to the second level of the plant and deposited them on other conveyors capable of running the berries into any one of 27 temporary holding bins. Bins numbered 1-24 held 250 bbls. of berries each. Bins 25, 26, and 27 held 400 bbls. each. All of the conveyors were controlled from a central control panel. It usually took from 7 to 8 minutes to back a truck onto a Kiwanee dumper, empty its contents, and leave the platform. At times some trucks had to wait several hours, however, before they could empty their contents. These waits occurred when the holding bins became full and there was no place in the receiving plant to temporarily store berries before further operations. The holding bins emptied onto conveyors on the first level of the plant. Once the bins were opened, the berries flowed onto the conveyors and started their way through the destoning (dry berries only), dechaffing, drying (water-harvested berries only), quality grading, and either bulk loading or bagging operations. Destoning, Dechaffing, and Drying Holding bins 25-27 were for wet (water-harvested) berries only. Holding bins 17-24 could be used for either wet or dry berries. Wet berries from these bins were taken directly to one of the three dechaffing units (destoning was unnecessary with water-harvested berries) which could process up to 1,500 bbls. per hour each. After dechaffing, these wet berries were taken to one of the three drying units where they were dried at rates up to 200 bbls. per hour per dryer. Holding bins 1-16 were for dry berries only. Berries from these bins were routed through one of three destoning units, each of which could process up to 1,500 bbls. of berries per hour, before going through a dechaffing unit. Frequently, both wet and dry berries were processed at the same time though the system. The wet berries would be processed through the part of the system that included the dryers, while the dry berries were processed through the area containing the destoning units. National Cranberry's current plant layout had two dechaffing units dedicated to wet berries, and one to dry berries. Superintendent Walliston had told O'Brien that, with an increasing percentage of wet berries coming to the plant, it might make sense to convert some of holding bins 1-16 so they could be used for wet berries also. This would cost $10,000 per bin. Or, perhaps, he had mentioned, a few new dryers might be needed. These would cost $60,000 each. He wondered what the benefits might be of adding more dryers and whether those benefits would warrant the cost. Quality Grading After destoning, dechaffing, and drying, berries were transported to large take-away conveyors that moved berries from the first level of the receiving building to the third level of the adjoining separator building. Here these take away conveyors became "feed conveyors" as they were now feeding berries into the jumbo separators (see Figure B). The jumbo separators identified three classes of berries - first quality berries, potential second-quality berries, and unacceptable berries. The first-quality berries went directly onto one of three take-away conveyors on the second level and were transported to the shipping area. The unacceptable berries fell through waste chutes into water-filled waste flumes on the first level and were floated off to the disposal area. The potential second-quality berries fell into the Bailey mills on the second level of the building. The Bailey mills separated the stream of incoming berries into second-quality berries and unacceptable berries. The Bailey mills operated on the same principle as the jumbo separators. Over the years the percentage of second-quality berries had consistently been close to 12%. Each of the three separator lines could process up to 450 bbls. per hour, but the rate of processing declined as the percentage of bad fruit increased. It was estimated that the average effective capacity was probably close to 400 bbls. per hour for each line. Bulking and Bagging Conveyors carried berries from the separator building into the shipping building, feeding berries onto any one of the three main flexible conveyors in the shipping area. Each of the three conveyors in the shipping area could be moved to feed berries into bagging stations, bulk bin stations, or bulk truck stations. The berries left RP1 in bulk trucks for shipment directly to the finish processing plant or in bins for storage at freezers with bulk storage capability. Scheduling the Work Force During the harvest season-September 1 to December 15 -the process fruit side of RP1 was operated seven days a week with either a 27 -member work force or a 53-member work force, depending on the relative volume of berry receipts. Will Walliston explained to Mel O'Brien, Last year, trucks arrived at 7:00, and we only staffed the dumpers and the bins, and then started the rest of the operation at 11:00. This year, with an increase in the percentage of wet berries that we expect, we're going to have to fire up the operation, on peak days, with two shifts - one from 7:00 to 3:00, and one from 3:00 to 11:00. I'm hoping that'll cut into last year's huge overtime expenditures and will limit the extra capital that we'll need to spend. But, that's what your report will help me decide. There were 27 employees at RP1 who were employed for the entire year; all others were hired for the season only. The 27 non-seasonal employees were all members of the Teamsters Union, as were 15 seasonal workers. Seasonal workers could work only between the dates of August 15 and December 25 by agreement with the union. Most seasonal workers were employed via a state employment agency that set up operations each fall. The employment agency helped in placing seasonal workers in the receiving plant and in harvesting jobs with the local growers. The pay rate for seasonal workers in the process fruit section was $8.00 per hour. They were paid the overtime rate of 1-1/2 times their straight-time rate for anything over 40 hours per week. The straight-time pay rate for the full-year employees averaged $13.00 per hour. When it was necessary to work beyond 11 p.m., a crew of only eight or nine workers was required to run the holding bins empty and do bulk loading. Although dry fruit could be held in the bins overnight, it was considered undesirable to hold wet fruit any longer than necessary, so wet fruit was always run out before shutting down. The plant never ran more than 22 hours a day, since at least 2 hours were required for cleaning and maintenance work. (Downtime due to unscheduled maintenance was very small; said Walliston: "We ran 350,000 bbls. through the wet system in 1995 and we were down a total of less than 8 hours.") On February 14, 1996, Hugo Schaeffer, vice president of operations at the National Cranberry Cooperative (NCC), called his assistant, Mel O'Brien, into his office. Mel, I spent all day yesterday reviewing last fall's process fruit operations at receiving plant \#1 [RP1] with Will Walliston, the superintendent, and talking with the co-op members [growers] in that area. It's obvious to me that we haven't solved our problems at that plant, yet. Even though we spent $200,000 last winter for a fifth Kiwanee dumper at RP1, our overtime costs were still out of control last fall, and the growers are still upset that their trucks and drivers had to spend so much time waiting to unload process fruit into the receiving plant. I can't blame them for being upset. They are the owners of this cooperative, and they resent having to lease trucks and hire drivers to get the berries out of the field and then watch them stand idle, waiting to unload 1. Walliston thinks that the way to avoid these problems next fall is to increase our capacity by buying some new equipment. I want you to go out there and take a hard look at the RP1 operation and find out what we need to do to improve operations before the 1996 crop comes in. We're going to have to move quickly if we are going to order new equipment, since the purchasing and installation lead times are in excess of six months. By the way, the growers in that region indicated that they plan on about the same size crop this year as last. But it looks like the percentage of water-harvested berries this year will increase to 70% of total process fruit from last year's 58%, which means that we'll have to change the way we schedule our daily operations. NCC and the Cranberry Industry NCC was an organization formed and owned by growers of cranberries to process and market their berries. In recent years, 99% of all sales of cranberries were made by the various cooperatives active in the cranberry industry. NCC was one of the larger cooperatives and had operations in all the principal growing areas of North America: Massachusetts, New Jersey, Wisconsin, Washington, Oregon, British Columbia, and Nova Scotia. Table A contains industry data for U.S. production and sales of cranberries. Some significant trends are observable in Table A. Probably the most important trend was the increasing surplus of cranberries produced over those utilized. This surplus was serious enough by 1993 for the growers to resort to the Agriculture Marketing Agreement Act of 1937. Under this act, growers can regulate and control the size of an agricultural crop if the federal government and more than two-thirds of the growers agree to a plan for crop restriction. In 1993, 87\% of the growers agreed (making it binding on the others also) that no new acreage was to be developed over the next six years and that each grower would have a maximum allotment at the end of six years equal to the average of the grower's best two years from 1993 through 1998. In 1995 the growers resorted to the Agriculture Marketing Agreement Act once again. Under the Cranberry Marketing Order of 1995, the growers and the government agreed that 10% of the 1995 crop should be set aside. The set aside berries (berries that are either destroyed or used in a way that will not influence the market price) amounted to more than 200,000 barrels (bbls). (A barrel of cranberries weighs 100lbs.) Handlers physically set aside 10% of the berries before harvesting, under the supervision of a committee of growers and representatives from the Department of Agriculture. National Cranberry Cooperative, 1996 688122 Another important trend was the increasing mechanization of cranberry harvesting. Water harvesting, in particular, was developing rapidly in the vicinity of receiving plant No. 1. Under the traditional dry harvesting, berries were hand-picked from the bushes. In water harvesting, the bogs were flooded, the berries were mechanically shaken from the bushes, and the berries then were collected easily since they floated to the surface of the water. Water harvesting could result in yields up to 20% greater than those obtained via dry harvesting, but it caused some damage and it shortened the time that harvested fruit could be held prior to either its use or freezing for long-term storage. Water harvesting had developed at a remarkable rate in some areas. Receiving plant No. 1 received 25,000 bbls. of water-harvested fruit in 1993, 125,000 bbls. in 1994, and 350,000 bbls. in 1995. Receiving Plant No. 1 (RP1) RP1 received both "fresh" fruit and "process" fruit during a season that usually started early in September and was effectively finished by early December (see Figure A). The fresh fruit operation (preparing cranberries for sale as whole fresh fruit) was completely separate from the process fruit operation (that prepares cranberries for juice, canning, freezing, and other process fruit products) and took the fruit from receiving through packaging. This case is concerned only with the process fruit operation. Figure A Daily Delivery of Both Fresh and Process Berries to RP1 The handling of process fruit at RP1 was highly mechanized. The process could be classified into several operations: receiving and testing, dumping, temporary holding, destoning, 2 dechaffing 33 drying, separation, and bulking and bagging. The objective of the total process was to gather bulk berries and prepare them for storage and processing into frozen fresh berries, sauce, and juice. Process Fruit Receiving Bulk trucks carrying process berries arrived at RP1 randomly throughout the day as shown in Exhibit 1. The average truck delivery was 75 bbls. When the trucks arrived at RP1 they were weighed, and the gross weight and the tare (empty) weight were recorded. Prior to unloading, a sample of about 30lbs. of fruit (0.3bbl.) was taken from the truck. Later, this sample would be run through a small version of the cleaning and drying process used in the plant. By comparing the before and after weight of this sample, it was possible to estimate the percentage of the truck's net weight made up of clean, dry berries. At the same time, another sample was taken to determine the percentage of unusable berries (poor, smaller, and frosted berries) in the truck. The grower was credited for the estimated weight of the clean, dry, usable berries. (See Exhibit 2 for total 1995 deliveries of process berries.) At the time the truck was weighed, the truckload of berries was graded according to color. Using color pictures as a guide, the chief berry receiver classified the berries as Nos. 1, 2A, 2B, or 3, from poorest color (No. 1) to best (No. 3). There was a premium of $1.50 per bbl. paid for No. 3 berries, since color was considered to be a very important attribute of both juice products and whole sauce. Whenever there was any question about whether or not a truckload was No. 2B or No. 3 berries, the chief berry receiver usually chose No. 3. In 1995 the $1.50 premium was paid on about 450,000 bbls. of berries. When these berries were used, however, it was found that only about half of them were No. 3's. To improve this yield, Schaeffer was considering the installation of a light meter system for color grading. This system was projected to cost $40,000 and would require a full-time skilled operator at the same pay grade as the chief berry receiver. Temporary Holding After a truckload of process berries had been weighed, sampled, and color graded, the truck moved to one of the five Kiwanee dumpers. The truck was backed onto the dumper platform which then tilted until the contents of the truck dumped onto one of five rapidly moving belt conveyors. Each of the five conveyors took the berries to the second level of the plant and deposited them on other conveyors capable of running the berries into any one of 27 temporary holding bins. Bins numbered 1-24 held 250 bbls. of berries each. Bins 25, 26, and 27 held 400 bbls. each. All of the conveyors were controlled from a central control panel. It usually took from 7 to 8 minutes to back a truck onto a Kiwanee dumper, empty its contents, and leave the platform. At times some trucks had to wait several hours, however, before they could empty their contents. These waits occurred when the holding bins became full and there was no place in the receiving plant to temporarily store berries before further operations. The holding bins emptied onto conveyors on the first level of the plant. Once the bins were opened, the berries flowed onto the conveyors and started their way through the destoning (dry berries only), dechaffing, drying (water-harvested berries only), quality grading, and either bulk loading or bagging operations. Destoning, Dechaffing, and Drying Holding bins 25-27 were for wet (water-harvested) berries only. Holding bins 17-24 could be used for either wet or dry berries. Wet berries from these bins were taken directly to one of the three dechaffing units (destoning was unnecessary with water-harvested berries) which could process up to 1,500 bbls. per hour each. After dechaffing, these wet berries were taken to one of the three drying units where they were dried at rates up to 200 bbls. per hour per dryer. Holding bins 1-16 were for dry berries only. Berries from these bins were routed through one of three destoning units, each of which could process up to 1,500 bbls. of berries per hour, before going through a dechaffing unit. Frequently, both wet and dry berries were processed at the same time though the system. The wet berries would be processed through the part of the system that included the dryers, while the dry berries were processed through the area containing the destoning units. National Cranberry's current plant layout had two dechaffing units dedicated to wet berries, and one to dry berries. Superintendent Walliston had told O'Brien that, with an increasing percentage of wet berries coming to the plant, it might make sense to convert some of holding bins 1-16 so they could be used for wet berries also. This would cost $10,000 per bin. Or, perhaps, he had mentioned, a few new dryers might be needed. These would cost $60,000 each. He wondered what the benefits might be of adding more dryers and whether those benefits would warrant the cost. Quality Grading After destoning, dechaffing, and drying, berries were transported to large take-away conveyors that moved berries from the first level of the receiving building to the third level of the adjoining separator building. Here these take away conveyors became "feed conveyors" as they were now feeding berries into the jumbo separators (see Figure B). The jumbo separators identified three classes of berries - first quality berries, potential second-quality berries, and unacceptable berries. The first-quality berries went directly onto one of three take-away conveyors on the second level and were transported to the shipping area. The unacceptable berries fell through waste chutes into water-filled waste flumes on the first level and were floated off to the disposal area. The potential second-quality berries fell into the Bailey mills on the second level of the building. The Bailey mills separated the stream of incoming berries into second-quality berries and unacceptable berries. The Bailey mills operated on the same principle as the jumbo separators. Over the years the percentage of second-quality berries had consistently been close to 12%. Each of the three separator lines could process up to 450 bbls. per hour, but the rate of processing declined as the percentage of bad fruit increased. It was estimated that the average effective capacity was probably close to 400 bbls. per hour for each line. Bulking and Bagging Conveyors carried berries from the separator building into the shipping building, feeding berries onto any one of the three main flexible conveyors in the shipping area. Each of the three conveyors in the shipping area could be moved to feed berries into bagging stations, bulk bin stations, or bulk truck stations. The berries left RP1 in bulk trucks for shipment directly to the finish processing plant or in bins for storage at freezers with bulk storage capability. Scheduling the Work Force During the harvest season-September 1 to December 15 -the process fruit side of RP1 was operated seven days a week with either a 27 -member work force or a 53-member work force, depending on the relative volume of berry receipts. Will Walliston explained to Mel O'Brien, Last year, trucks arrived at 7:00, and we only staffed the dumpers and the bins, and then started the rest of the operation at 11:00. This year, with an increase in the percentage of wet berries that we expect, we're going to have to fire up the operation, on peak days, with two shifts - one from 7:00 to 3:00, and one from 3:00 to 11:00. I'm hoping that'll cut into last year's huge overtime expenditures and will limit the extra capital that we'll need to spend. But, that's what your report will help me decide. There were 27 employees at RP1 who were employed for the entire year; all others were hired for the season only. The 27 non-seasonal employees were all members of the Teamsters Union, as were 15 seasonal workers. Seasonal workers could work only between the dates of August 15 and December 25 by agreement with the union. Most seasonal workers were employed via a state employment agency that set up operations each fall. The employment agency helped in placing seasonal workers in the receiving plant and in harvesting jobs with the local growers. The pay rate for seasonal workers in the process fruit section was $8.00 per hour. They were paid the overtime rate of 1-1/2 times their straight-time rate for anything over 40 hours per week. The straight-time pay rate for the full-year employees averaged $13.00 per hour. When it was necessary to work beyond 11 p.m., a crew of only eight or nine workers was required to run the holding bins empty and do bulk loading. Although dry fruit could be held in the bins overnight, it was considered undesirable to hold wet fruit any longer than necessary, so wet fruit was always run out before shutting down. The plant never ran more than 22 hours a day, since at least 2 hours were required for cleaning and maintenance work. (Downtime due to unscheduled maintenance was very small; said Walliston: "We ran 350,000 bbls. through the wet system in 1995 and we were down a total of less than 8 hours.")

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts