Question: Question 2 (25 marks) Larson-Miller parameter is a common means used to estimate the lifetime of a material that depends on temperature and stress level.

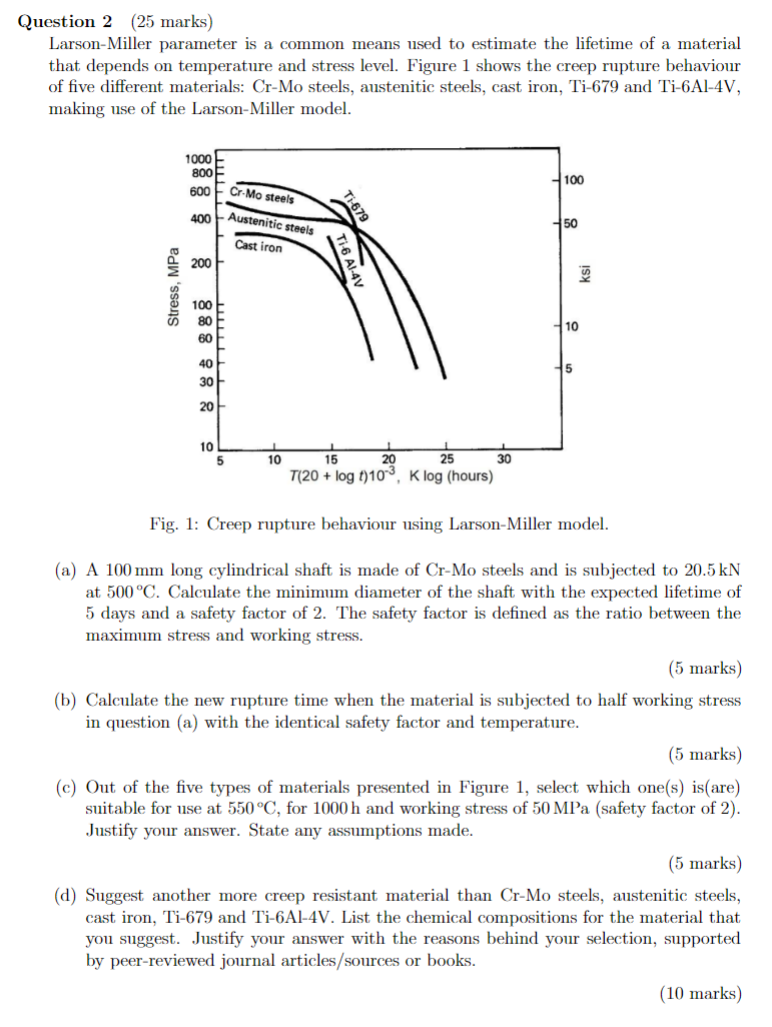

Question 2 (25 marks) Larson-Miller parameter is a common means used to estimate the lifetime of a material that depends on temperature and stress level. Figure 1 shows the creep rupture behaviour of five different materials: Cr-Mo steels, austenitic steels, cast iron, Ti-679 and Ti-6Al-4V, making use of the Larson-Miller model. 1000 800 100 600 Cr-Mo steels 400 Austenitic steels Ti 679 150 Cast iron 200 Stress, MPa Ti 6 AI-4V 100 80 60 10 40 15 30 20 10 5 10 15 20 25 30 T(20 + log t)10 Klog (hours) Fig. 1: Creep rupture behaviour using Larson-Miller model. (a) A 100 mm long cylindrical shaft is made of Cr-Mo steels and is subjected to 20.5 kN at 500C. Calculate the minimum diameter of the shaft with the expected lifetime of 5 days and a safety factor of 2. The safety factor is defined as the ratio between the maximum stress and working stress. (5 marks) (b) Calculate the new rupture time when the material is subjected to half working stress in question (a) with the identical safety factor and temperature. (5 marks) (C) Out of the five types of materials presented in Figure 1, select which one(s) is(are) suitable for use at 550 C, for 1000 h and working stress of 50 MPa (safety factor of 2). Justify your answer. State any assumptions made. (5 marks) (d) Suggest another more creep resistant material than Cr-Mo steels, austenitic steels, cast iron, Ti-679 and Ti-6Al-4V. List the chemical compositions for the material that you suggest. Justify your answer with the reasons behind your selection, supported by peer-reviewed journal articles/sources or books. (10 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts