Question: Question 2 a) Describe how a Failure Mode Effect and Criticality Analysis (FMECA) is carried out. [15 marks] b) Provide an example of a typical

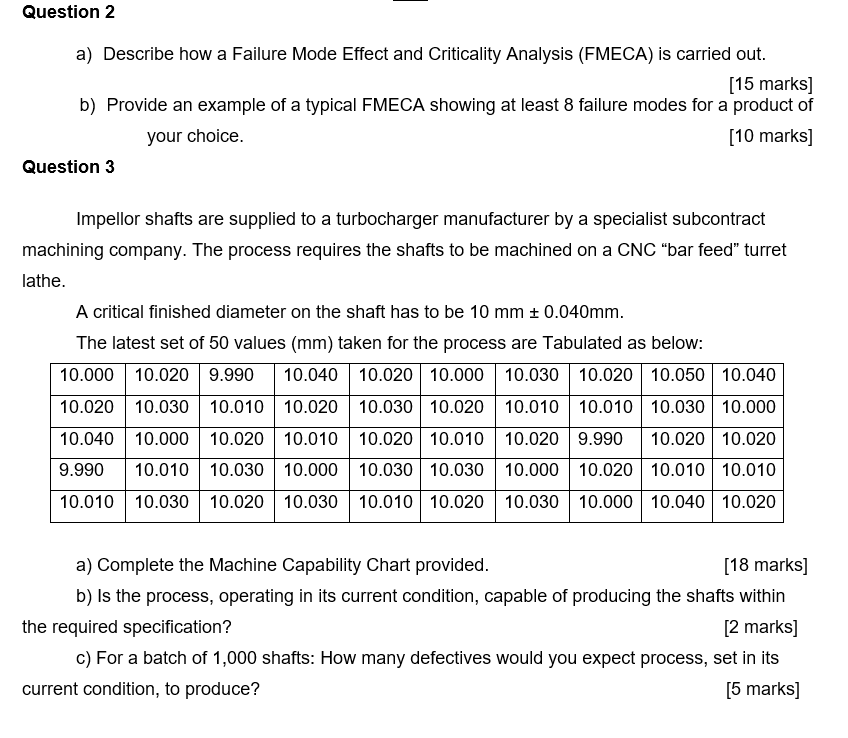

Question 2 a) Describe how a Failure Mode Effect and Criticality Analysis (FMECA) is carried out. [15 marks] b) Provide an example of a typical FMECA showing at least 8 failure modes for a product of your choice. [10 marks] Question 3 Impellor shafts are supplied to a turbocharger manufacturer by a specialist subcontract machining company. The process requires the shafts to be machined on a CNC bar feed" turret lathe. A critical finished diameter on the shaft has to be 10 mm + 0.040mm. The latest set of 50 values (mm) taken for the process are Tabulated as below: 10.000 10.020 9.990 10.040 10.020 10.000 10.030 10.020 10.050 10.040 10.020 10.030 10.010 10.020 10.030 10.020 10.010 10.010 10.030 10.000 10.040 10.000 10.020 10.010 10.020 10.010 10.020 9.990 10.020 10.020 9.990 | 10.010 | 10.030 10.000 10.030 10.030 10.000 10.020 10.010 10.010 | 10.010 | 10.030 | 10.020 10.030 10.010 10.020 10.030 10.000 10.040 10.020 a) Complete the Machine Capability Chart provided. (18 marks] b) is the process, operating in its current condition, capable of producing the shafts within the required specification? [2 marks] c) For a batch of 1,000 shafts: How many defectives would you expect process, set in its current condition, to produce? [5 marks] Question 2 a) Describe how a Failure Mode Effect and Criticality Analysis (FMECA) is carried out. [15 marks] b) Provide an example of a typical FMECA showing at least 8 failure modes for a product of your choice. [10 marks] Question 3 Impellor shafts are supplied to a turbocharger manufacturer by a specialist subcontract machining company. The process requires the shafts to be machined on a CNC bar feed" turret lathe. A critical finished diameter on the shaft has to be 10 mm + 0.040mm. The latest set of 50 values (mm) taken for the process are Tabulated as below: 10.000 10.020 9.990 10.040 10.020 10.000 10.030 10.020 10.050 10.040 10.020 10.030 10.010 10.020 10.030 10.020 10.010 10.010 10.030 10.000 10.040 10.000 10.020 10.010 10.020 10.010 10.020 9.990 10.020 10.020 9.990 | 10.010 | 10.030 10.000 10.030 10.030 10.000 10.020 10.010 10.010 | 10.010 | 10.030 | 10.020 10.030 10.010 10.020 10.030 10.000 10.040 10.020 a) Complete the Machine Capability Chart provided. (18 marks] b) is the process, operating in its current condition, capable of producing the shafts within the required specification? [2 marks] c) For a batch of 1,000 shafts: How many defectives would you expect process, set in its current condition, to produce? [5 marks]

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts