Question: Question 2 (a) Design a reorder point system for the product with the following information. Weekly demand for a product is 180 units. The annual

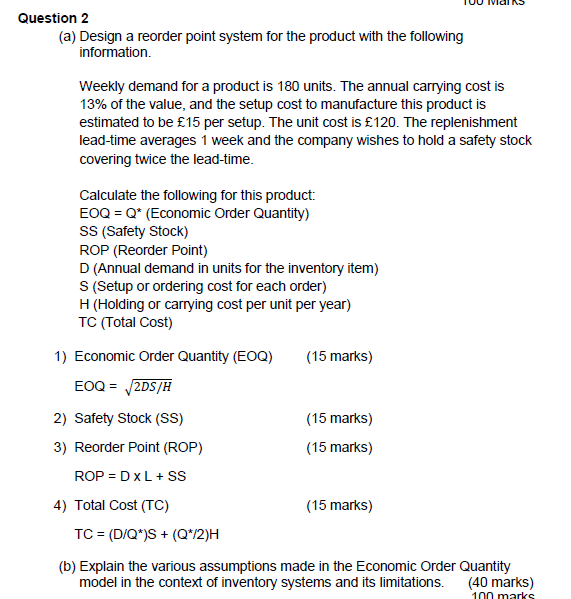

Question 2 (a) Design a reorder point system for the product with the following information. Weekly demand for a product is 180 units. The annual carrying cost is 13% of the value, and the setup cost to manufacture this product is estimated to be 15 per setup. The unit cost is 120. The replenishment lead-time averages 1 week and the company wishes to hold a safety stock covering twice the lead-time. Calculate the following for this product: EOQ = Q* (Economic Order Quantity) SS (Safety Stock) ROP (Reorder Point) D (Annual demand in units for the inventory item) S (Setup or ordering cost for each order) H (Holding or carrying cost per unit per year) TC (Total Cost) 1) Economic Order Quantity (EOQ) (15 marks) EOQ = 2/ 2) Safety Stock (SS) (15 marks) 3) Reorder Point (ROP) (15 marks) ROP = D x L + SS 4) Total Cost (TC) (15 marks) TC = (D/Q*)S + (Q*/2)H (b) Explain the various assumptions made in the Economic Order Quantity model in the context of inventory systems and its limitations. (40 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts