Question: Question 2 (a) Two wide plates are fabricated from a 4340 alloy steel. Each of these plates is then subjected to a different heat

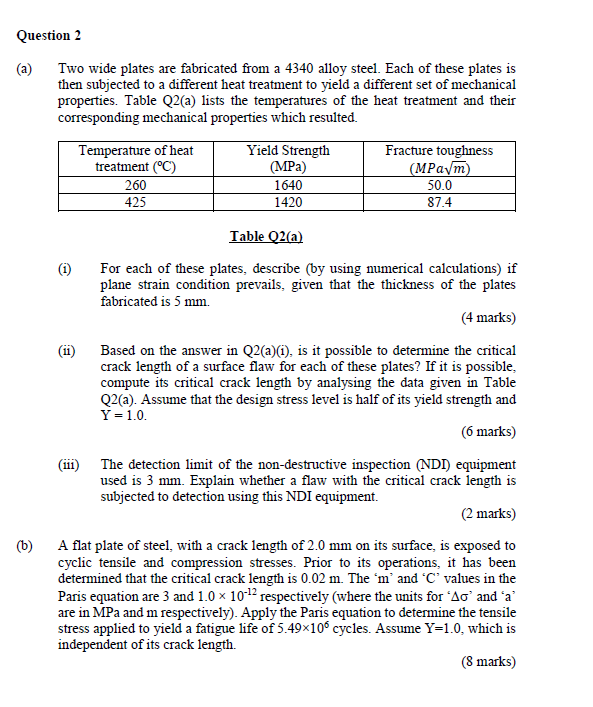

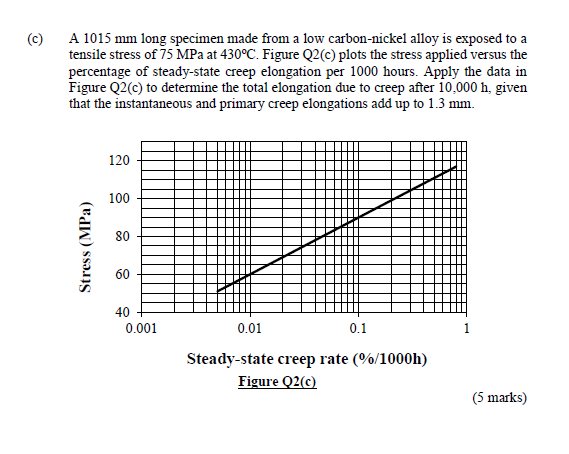

Question 2 (a) Two wide plates are fabricated from a 4340 alloy steel. Each of these plates is then subjected to a different heat treatment to yield a different set of mechanical properties. Table Q2(a) lists the temperatures of the heat treatment and their corresponding mechanical properties which resulted. Temperature of heat treatment (C) 260 425 Yield Strength (MPa) 1640 1420 Table Q2(a) Fracture toughness (MPam) 50.0 87.4 (b) (i) (11) For each of these plates, describe (by using numerical calculations) if plane strain condition prevails, given that the thickness of the plates fabricated is 5 mm. (4 marks) Based on the answer in Q2(a)(i), is it possible to determine the critical crack length of a surface flaw for each of these plates? If it is possible. compute its critical crack length by analysing the data given in Table Q2(a). Assume that the design stress level is half of its yield strength and Y = 1.0. (6 marks) (iii) The detection limit of the non-destructive inspection (NDI) equipment used is 3 mm. Explain whether a flaw with the critical crack length is subjected to detection using this NDI equipment. (2 marks) A flat plate of steel, with a crack length of 2.0 mm on its surface, is exposed to cyclic tensile and compression stresses. Prior to its operations, it has been determined that the critical crack length is 0.02 m. The 'm' and 'C' values in the Paris equation are 3 and 1.0 10-12 respectively (where the units for 'A' and 'a' are in MPa and m respectively). Apply the Paris equation to determine the tensile stress applied to yield a fatigue life of 5.4910 cycles. Assume Y=1.0, which is independent of its crack length. (8 marks) (c) A 1015 mm long specimen made from a low carbon-nickel alloy is exposed to a tensile stress of 75 MPa at 430C. Figure Q2(c) plots the stress applied versus the percentage of steady-state creep elongation per 1000 hours. Apply the data in Figure Q2(c) to determine the total elongation due to creep after 10,000 h, given that the instantaneous and primary creep elongations add up to 1.3 mm. Stress (MPa) 120 100 80 60 40 0.001 0.01 0.1 Steady-state creep rate (%/1000h) Figure Q2(c) 1 (5 marks)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts