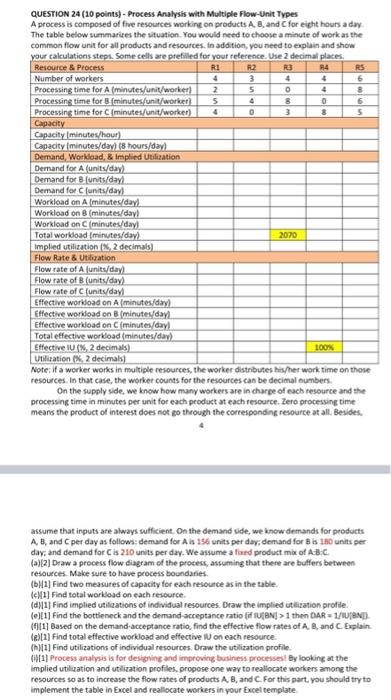

Question: QUESTION 24 (10 points) - Process Analysis with Multiple Flow-Unit Types A process is composed of five resources workine on products A, B, and C.

QUESTION 24 (10 points) - Process Analysis with Multiple Flow-Unit Types A process is composed of five resources workine on products A, B, and C. for eicht hours a day The table below summarires the situation. You would need to choose a minute of work as the common flow unit for all products and resoutces. in addition, you need to explain and show resources. In that case, the worker counts for the resources can be decimal numbers. On the supply side, we know how many workers are in charpe of each resource and the : processing time in minutes per unit for each peoduct at each resource. Zero processing time means the product of interest does not go through the corresponding resource at all. Besides. 4 assume that inputs are ahways sutficient. On the demand side, we know demands for products A, B, and C per day as follows: demand for A is 196 units per day; demand for B is 160 units per day; and demand for C is 210 units per day. We assume a fioed product max of A.B.C. (a) (2) Draw a process flow diagram of the process, assuming that there are buffers between resources. Make sure to have process boundafies. (b).1] Find two measures of capacity for each resource as in the table. (c).11] Find total workload on each fesource. (d) 11] Find implied utifiations of individual resources. Draw the implied ut titation profle. [9]11] Based on the demand-acceptance ratio, find the effective flow rates of A. B, and C. Explain. (8) [1] Find total effective workload and effective 10 on each resource. (h).1] Find utilizations of individual resources. Draw the utilization profile. (i) [1] Process analysis is for designing and imptoving bustiness procetses! Ey looking at the implied utiluation and utilization profiles, propose one way to reallocate workers among the resources so as to increase the flow rates of products A,B, and C. For this part, you should try to implement the table in Excel and reallocate workers in your Excel template. QUESTION 24 (10 points) - Process Analysis with Multiple Flow-Unit Types A process is composed of five resources workine on products A, B, and C. for eicht hours a day The table below summarires the situation. You would need to choose a minute of work as the common flow unit for all products and resoutces. in addition, you need to explain and show resources. In that case, the worker counts for the resources can be decimal numbers. On the supply side, we know how many workers are in charpe of each resource and the : processing time in minutes per unit for each peoduct at each resource. Zero processing time means the product of interest does not go through the corresponding resource at all. Besides. 4 assume that inputs are ahways sutficient. On the demand side, we know demands for products A, B, and C per day as follows: demand for A is 196 units per day; demand for B is 160 units per day; and demand for C is 210 units per day. We assume a fioed product max of A.B.C. (a) (2) Draw a process flow diagram of the process, assuming that there are buffers between resources. Make sure to have process boundafies. (b).1] Find two measures of capacity for each resource as in the table. (c).11] Find total workload on each fesource. (d) 11] Find implied utifiations of individual resources. Draw the implied ut titation profle. [9]11] Based on the demand-acceptance ratio, find the effective flow rates of A. B, and C. Explain. (8) [1] Find total effective workload and effective 10 on each resource. (h).1] Find utilizations of individual resources. Draw the utilization profile. (i) [1] Process analysis is for designing and imptoving bustiness procetses! Ey looking at the implied utiluation and utilization profiles, propose one way to reallocate workers among the resources so as to increase the flow rates of products A,B, and C. For this part, you should try to implement the table in Excel and reallocate workers in your Excel template