Question: Question 3 : We are producing four products, A . D , C and D on a CNC Machine whete each of these products requires

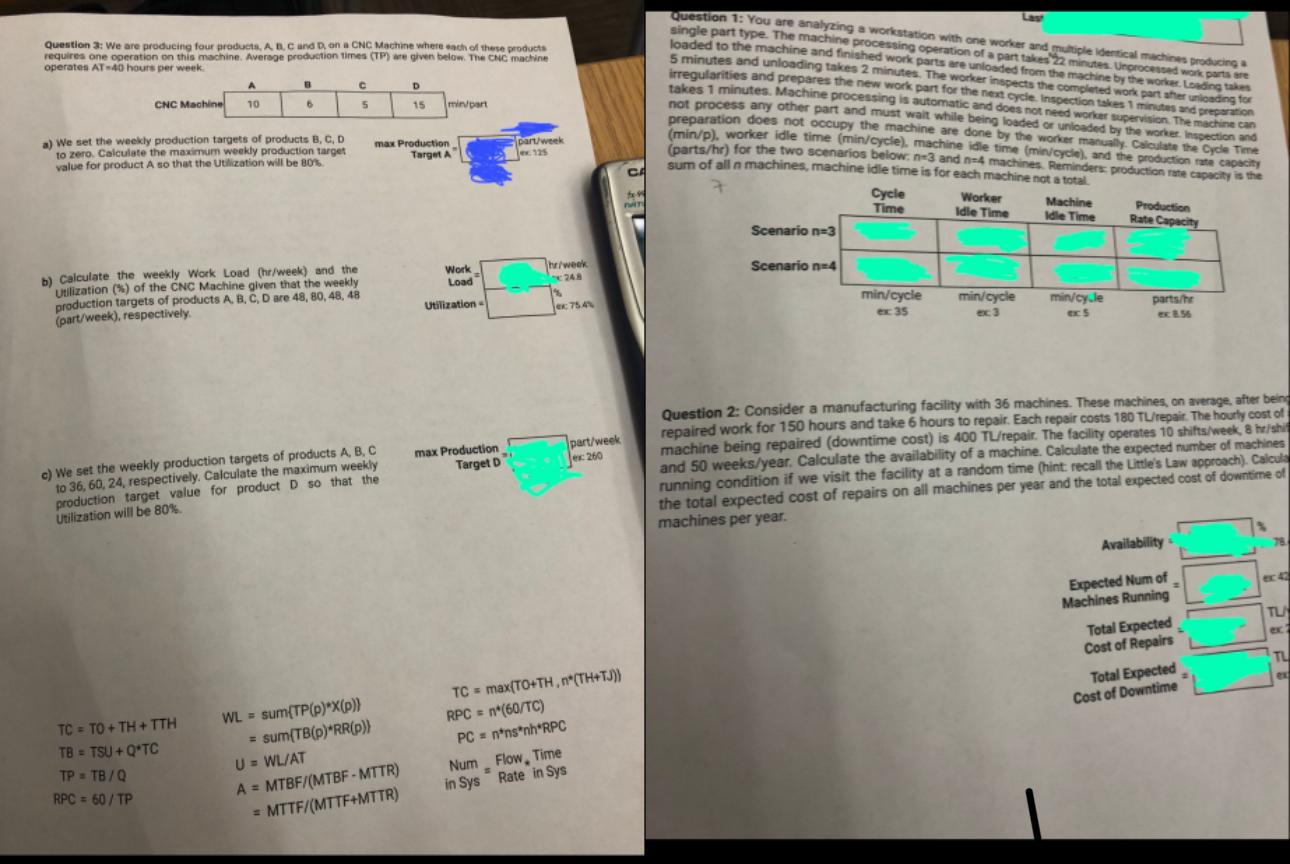

Question : We are producing four products, A D C and D on a CNC Machine whete each of these products requires one operation on this machine. Aversge production tirnes TP are given below. The Chic machine operates. AT hours per week.

a We set the weekly production targets of products B C D to zero. Calculate the maximum weekly production target value for product so that the Utilization will be

b Calculate the weekly Work Load hrweek and the Utilization of the CNC Machine given that the weekly production targets of products A B C D are partweek respectively.

c We set the weekly production targets of products A B C to respectively. Calculate the maximum weekly production target value for product so that the Utilization will be

TSU

single part type The maching a workstation with one worker and gultiple identical machines producing a loaded to the machine and finished work parts are unlo part takes minutes. Unopocesoed work parts are minutes and unloading takes minutes. The worker inspects the completed work part afier uning taking to irregularities and prepares the new work part for the Rext orcle. Inspection takes minutes and sreparation not process any other part and must wait whille being loes not need worker supervision. The machine can preparation does not occupy the machine are done by the worker manually. Caloulate the Cycle Time worker idle time minoycle machine idle time minoycle and the production rate capacily partshr for the two scenarios below: and machines. Reminders: production rate capecity is the sum of all machines, machine idle time is for each machine not a total.

Question : Consider a manufacturing facility with machines. These machines, on average, after being repaired work for hours and take hours to repair. Each repair costs TUrepair. The hourly cost of machine being repaired downtime cost is TLrepair The facility operates shiftsweek shi and weeksyear Calculate the availability of a machine. Calculate the expected number of mactines running condition if we visit the facility at a random time hint: recall the Lutle's Law approach Calcula the total expected cost of repairs on all machines per year and the total expected cost of downtime of machines per year.

max

Num Flow, Time in Sys "Rate in Sys

ANSWER THE QUISTION CLEARLY

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock