Question: Question 7. (18 Marks) A company uses a single sampling plan to inspect the received lots from one of its suppliers. During the inspection, if

Question 7. (18 Marks) A company uses a single sampling plan to inspect the received lots from one of its suppliers. During the inspection, if a lot is rejected, all the products in that lot will be inspected. Analysis of the past few purchases shows that the average reliability of the supplier is 97%. The company inspects 90 items in each lot and if the number of defective items is more than 4, then the lot will be rejected. The size of each lot is 5000 units.

- Calculate the average outgoing quality (4 Marks)

- Due to the limited purchases from the supplier, the company is not fully confident about the reliability of the supplier. They estimate that the possible scenarios for the reliability of the supplier would be 90%, 95% or 97%. Find the worst average outgoing quality for the company considering the possible scenarios for the reliability of the supplier (6 Marks)

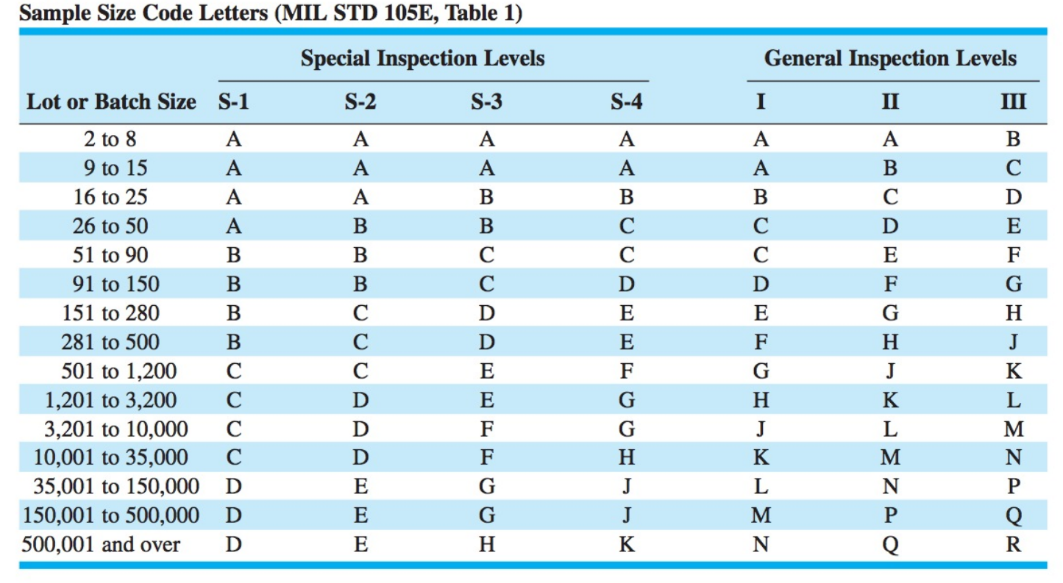

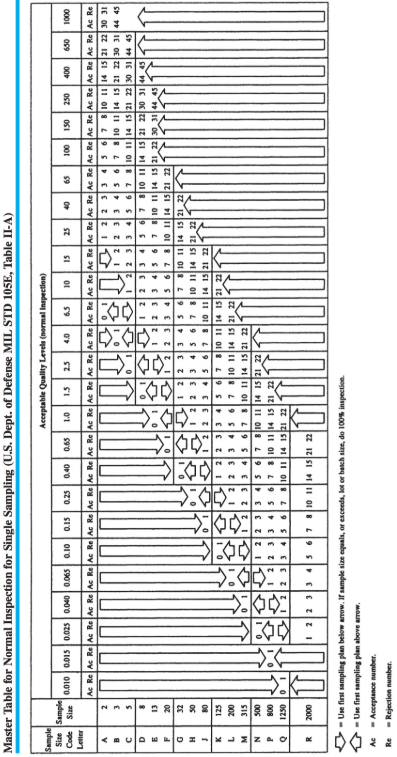

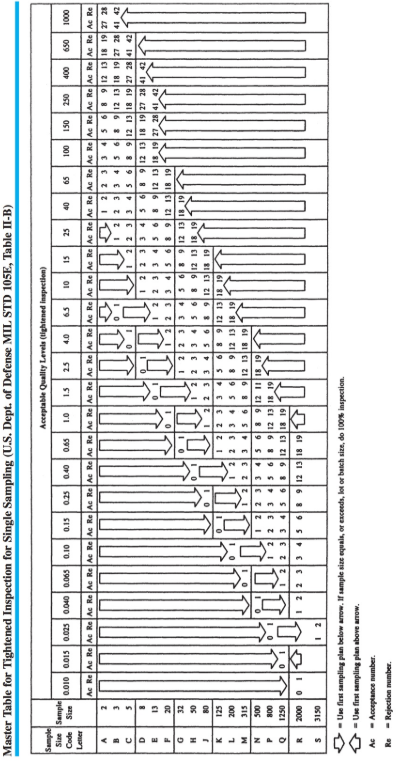

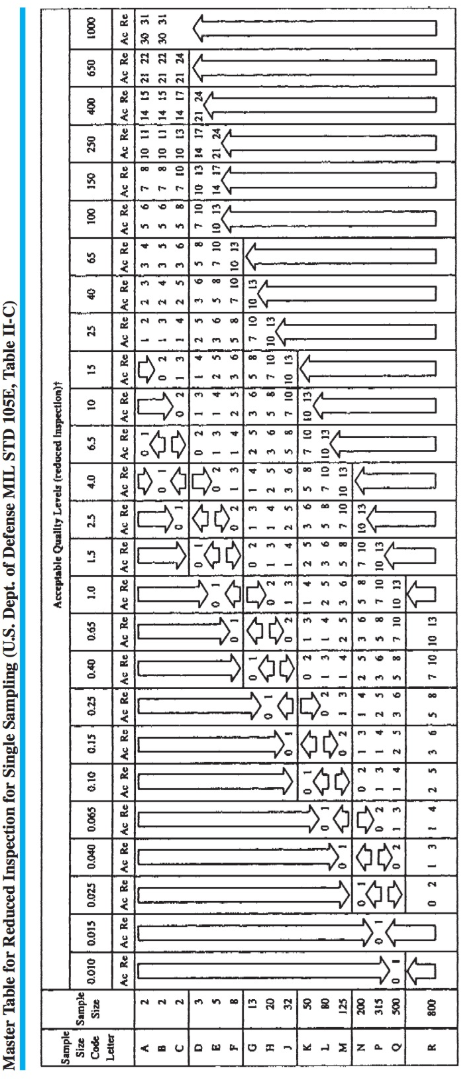

- The company is planning to revise its inspection plan as well. They are planning to use Military Standard 105E to identify the proper inspection plan. The company has no issue on sample size and they believe they can use Level III general inspection. Also, their desired average quality limit is 1%. What are the specifications of sampling plan for normal, tightened, and reduced inspections? Related tables are provided at the end of the sheet. Under which condition in the reduced single sampling plan, we accept the lot but for the next lot we should switch from reduced to normal single sampling plan? (8 Marks)

Sample Size Code Letters (MIL STD 105E, Table 1) Special Inspection Levels General Inspection Levels Lot or Batch Size S-1 S-2 S-3 S-4 I II III A A A B A A B A A A A B A A A B B B D A B B D D E B D 2 to 8 9 to 15 16 to 25 26 to 50 51 to 90 91 to 150 151 to 280 281 to 500 501 to 1,200 1,201 to 3,200 3,201 to 10,000 10,001 to 35,000 35,001 to 150,000 150,001 to 500,000 500,001 and over H E E A B D E F G H J K L EMO ALOM ZAO B B B D D D E F G F G H J K L M N P E F F G H L M N D D E E E G J G M J K ZAO H N Master Table for Normal Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-A) 1000 Letter A 2 WN 5 D E F 00:5 13 20 32 30 DECISIONS 3:00 Sample Acceptable Quality Levels (normal Inspection) Sample Code Sise 2.010 001 0.025 0.00 0.06 0.100.150.250.40065 1.0 1.5 25 40 6.5 100 150 250 400 650 Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ae Re Ac Re Ac Re AC Re Ac Re Ar Re Ac Re Ac Re Ac Re Ae Re Ac Re Ac Re Ac Re Ae Re 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 30 31 1 2 2 3 3 4 3 10 11 14 15 21 230 31 44 45 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 30 31 44 45 12233367810 11 14 15 21 22 30 314 451 1 212 213 7 10 11 14 15 21 22 30 31144 2 3 3 4 5 6 7 8 10 11 14 1521 22 G 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 1 2 2 3 3 7 10 11 14 15 21 22 232361 310 11 14 15 21 22 I 22 33 367 310 11 14 15 21 22 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 13 2 3 3 4 5 6 8 10 11 14 15 21 22 N 1 212 213 15 8 10 14 15 21 22 P 2335 610 11 14 15 21 22 H 09 K 125 200 315 500 00 1 M N lezl 30 300 000 008 o 1250 2 1 : 2 R 2000 I 22 33 48 10 15 21 22 Use first sampling plan below stow. If sample size equals, or exceeds, lot or batch size, do 100% inspection - Use first sampling plan above arrow. Ae-Acceptance number. Re-Rejection number Master Table for Tightened Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-B) Leer 5 D 8 13 E F 61 G t: | Sample Acceptable Quality Levels (lightened inspection) Sime Sample Code Size 0.010001 0.025 0.00 0.00 0.10 0.15 0.250.400.45 1.0 1.5 25 40 5 10 15 25 4065 100 150 250 400 650 1000 Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re 2 21 2 2 3 3 4 5 6 8 9 12 13 18 19 27 28 122 3 3 +56 912 1918 19 27 2842 1 2 2 3 3 3 3 9 12 13 18 19 27 28 41 42 ! 22:23 18 19 27 28 1 2 2 3 338 12 13 13 19 28 41 42 20 22 3 3 4 5 6 8 12 13 18 19 32 1 2 2 3 3 4 5 6 8 912 13 18 19 80 2 2 3 3 4 3 6 3 9 12 13 13 19 1 2 2 3 3 4 5 6 8 12 13 18 19 200 1 2 2 3 3 4 5 6 8 9 12 13 18 19 1 2 2 3 3 4 5 6 8 12 13 18 19 500 1 2 2 3 4 5 6 8 9 12 10 18 19 P 800 1 2 2 3 3 6 9 12 13 18 19 1250 2 3 3 568 12 15 18 19 2000 01 1 312 313 312 1913 191 3150 12 H OS 125 K L M N 315 19 SLEE || SE Q R s - Un flest sampling plan below arrow. If sample size equals, or exceeds, lot or batch size, do 100% inspection - Uwe first sampling plan above row. Ac - Acceptance number. Re - Rejection number. OZIRO NNN 100K OLA cold 100 2006 0.025 0.040 0.065 0.10 Re Ac Re Ac Relac Relac Re Ac Re Ac Ro Ac Re Ac ReA zl TT N WN N N LA A a N N : 1 th, 00-F A Nm T 0.15 0.250.400.65 Master Table for Reduced Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-C) N N 100 bo ould N - i MOD. 2 N NOWN - - 0 9 AN AN CD N 9 LA N - 2002 2 Novu N - Vo Acceptable Quallty Levels (reduced Inspection) O O 9 00) a ReAc Rc Ac Re Ac Rc Ac Rc Ac Re Ac Rc Ac Rc Ac Re Ac Re Ac Rc N N n N> a N N 22 mn LA on a WN 019 UA A NNN 40 $ De au A | 01 JOUL 8 65 GO ouuu 100 Rela -- 3/14 1721 g a *** $ EuH AN Sample Size Code Letters (MIL STD 105E, Table 1) Special Inspection Levels General Inspection Levels Lot or Batch Size S-1 S-2 S-3 S-4 I II III A A A B A A B A A A A B A A A B B B D A B B D D E B D 2 to 8 9 to 15 16 to 25 26 to 50 51 to 90 91 to 150 151 to 280 281 to 500 501 to 1,200 1,201 to 3,200 3,201 to 10,000 10,001 to 35,000 35,001 to 150,000 150,001 to 500,000 500,001 and over H E E A B D E F G H J K L EMO ALOM ZAO B B B D D D E F G F G H J K L M N P E F F G H L M N D D E E E G J G M J K ZAO H N Master Table for Normal Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-A) 1000 Letter A 2 WN 5 D E F 00:5 13 20 32 30 DECISIONS 3:00 Sample Acceptable Quality Levels (normal Inspection) Sample Code Sise 2.010 001 0.025 0.00 0.06 0.100.150.250.40065 1.0 1.5 25 40 6.5 100 150 250 400 650 Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ae Re Ac Re Ac Re AC Re Ac Re Ar Re Ac Re Ac Re Ac Re Ae Re Ac Re Ac Re Ac Re Ae Re 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 30 31 1 2 2 3 3 4 3 10 11 14 15 21 230 31 44 45 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 30 31 44 45 12233367810 11 14 15 21 22 30 314 451 1 212 213 7 10 11 14 15 21 22 30 31144 2 3 3 4 5 6 7 8 10 11 14 1521 22 G 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 1 2 2 3 3 7 10 11 14 15 21 22 232361 310 11 14 15 21 22 I 22 33 367 310 11 14 15 21 22 1 2 2 3 3 4 5 6 7 8 10 11 14 15 21 22 13 2 3 3 4 5 6 8 10 11 14 15 21 22 N 1 212 213 15 8 10 14 15 21 22 P 2335 610 11 14 15 21 22 H 09 K 125 200 315 500 00 1 M N lezl 30 300 000 008 o 1250 2 1 : 2 R 2000 I 22 33 48 10 15 21 22 Use first sampling plan below stow. If sample size equals, or exceeds, lot or batch size, do 100% inspection - Use first sampling plan above arrow. Ae-Acceptance number. Re-Rejection number Master Table for Tightened Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-B) Leer 5 D 8 13 E F 61 G t: | Sample Acceptable Quality Levels (lightened inspection) Sime Sample Code Size 0.010001 0.025 0.00 0.00 0.10 0.15 0.250.400.45 1.0 1.5 25 40 5 10 15 25 4065 100 150 250 400 650 1000 Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re 2 21 2 2 3 3 4 5 6 8 9 12 13 18 19 27 28 122 3 3 +56 912 1918 19 27 2842 1 2 2 3 3 3 3 9 12 13 18 19 27 28 41 42 ! 22:23 18 19 27 28 1 2 2 3 338 12 13 13 19 28 41 42 20 22 3 3 4 5 6 8 12 13 18 19 32 1 2 2 3 3 4 5 6 8 912 13 18 19 80 2 2 3 3 4 3 6 3 9 12 13 13 19 1 2 2 3 3 4 5 6 8 12 13 18 19 200 1 2 2 3 3 4 5 6 8 9 12 13 18 19 1 2 2 3 3 4 5 6 8 12 13 18 19 500 1 2 2 3 4 5 6 8 9 12 10 18 19 P 800 1 2 2 3 3 6 9 12 13 18 19 1250 2 3 3 568 12 15 18 19 2000 01 1 312 313 312 1913 191 3150 12 H OS 125 K L M N 315 19 SLEE || SE Q R s - Un flest sampling plan below arrow. If sample size equals, or exceeds, lot or batch size, do 100% inspection - Uwe first sampling plan above row. Ac - Acceptance number. Re - Rejection number. OZIRO NNN 100K OLA cold 100 2006 0.025 0.040 0.065 0.10 Re Ac Re Ac Relac Relac Re Ac Re Ac Ro Ac Re Ac ReA zl TT N WN N N LA A a N N : 1 th, 00-F A Nm T 0.15 0.250.400.65 Master Table for Reduced Inspection for Single Sampling (U.S. Dept. of Defense MIL STD 105E, Table II-C) N N 100 bo ould N - i MOD. 2 N NOWN - - 0 9 AN AN CD N 9 LA N - 2002 2 Novu N - Vo Acceptable Quallty Levels (reduced Inspection) O O 9 00) a ReAc Rc Ac Re Ac Rc Ac Rc Ac Re Ac Rc Ac Rc Ac Re Ac Re Ac Rc N N n N> a N N 22 mn LA on a WN 019 UA A NNN 40 $ De au A | 01 JOUL 8 65 GO ouuu 100 Rela -- 3/14 1721 g a *** $ EuH AN

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts