Question: Question Here: Target capacity .Based on the data provided, choose a target production capacity (in burgers per week) for what you think NoBull will need

Question Here:

Target capacity

- .Based on the data provided, choose a target production capacity (in burgers per week) for what you think NoBull will need to meet demand by the end of 2012.

- Explain why you chose this target.

All relevant information:

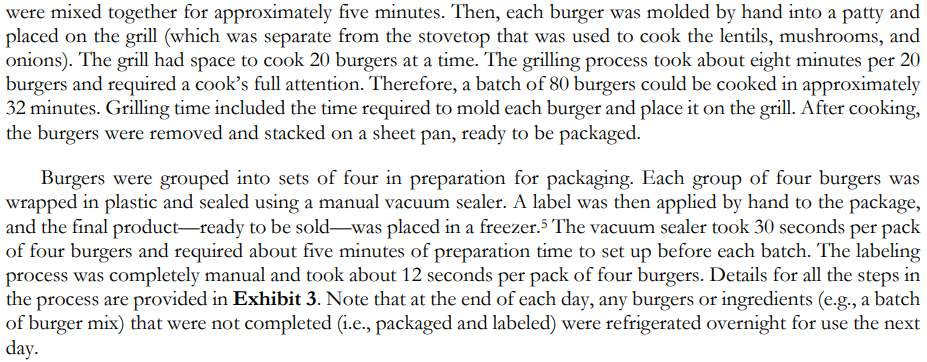

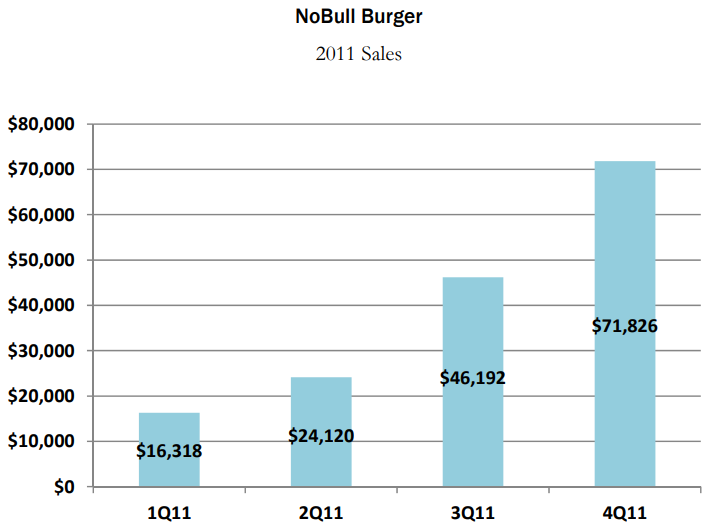

were mixed together for approximately ve minutes. Then, each burger was molded by hand into a patty and placed on the grill (which was separate from the stovetop that was used to cook the lentils, mushrooms, and onions). The grill had space to cook 20 burgers at a time. The grilling process took about eight minutes per 20 burgers and required a cook's Jll attention. Therefore, a batch of 80 burgers could be cooked in approximately 32 minutes. Grilling time included the time required to mold each burger and place it on the grill. fter cooking, the burgers were removed and stacked on a sheet pan, ready to be packaged. Burgers were grouped into sets of four in preparation for packaging. Each group of four burgers was wrapped in plastic and sealed using a manual vacuum sealer. A label was then applied by hand to the package, and the nal productready to be soldwas placed in a freezer.5 The vacuum sealer took 30 seconds per pack of four burgers and required about ve minutes of preparation time to set up before each batch. The labeling process was completely manual and took about 12 seconds per pack of four burgers. Details for all the steps in the process are provided in Exhibit 3. Note that at the end of each day, any burgers or ingredients (eg, a batch of burger mix) that were not completed (Le, packaged and labeled) were refrigerated overnight for use the next day. NoBull Burger Cooking and Setup Times for Burger Production Labor Days/Week Hours/Day Standard Batch Size (# of Burgers) 80 Burgers/Package Step 1 Setup Time (min/batch) Cook Time (min/batch) Lentils 50* *Cooking the lentils requires a cook's time for approximately half of the 50-minute cook time. The remaining time can be used to perform other steps. Note that the stovetop can hold up to four pots at once. Step 2 Setup Time (min/batch) Cook Time (min/batch) Mushrooms 10 6 Onions 10 Step 3 Setup Time (min/batch) Cook Time (min/20 burgers) Cooking Burgers 5 8 Step 4 Setup Time (min/batch) Operation Time (sec/4 burgers) Packaging 5 30 Labeling 12After the mushrooms and onions were cooked, they were added to the cooked lentils along with spinach, carrots, and some proprietary spices to complete the mushroom burger mixture. The ingredients for a batch NoBull Burger 2011 Sales $80,000 $70,000 $60,000 $50,000 $40,000 $71,826 $30,000 $46,192 $20,000 $10,000 $24,120 $16,318 $0 1Q11 2Q11 3Q11 4Q11Cu went Operations NoBull's current production process consisted of four basic steps: (1) cooking the lentils; (2) cooking additional ingredients; (3) creating the burger mix and cooking the burgers; and (4) packaging and labeling the burgers. In its kitchen, NoBull had one stove and one grill. The unwrap was used to cook the lentils (step 1); the riser was was used to broil the additional ingredients (step 2). The grill was used to cook the burgers (step 3). Currently, NoBull made only two varieties of burgers: original and mushroom. To analyze the production process, the Raymonds chose to focus on the mushroom burger. Each batch consisted of approximately 80 burgers. The batch size had been determined roughly based on pot sizes as well as concerns about the impact a greater number of burgers per batch could have on quality. The first step in the process was to cook the lentils, which formed the base for the burger mix- One pot of lentils was used per batch of 80 burgers; a pot took approximately 50 minutes to cook. With the current stovetop, up to four pots of lentils could be cooked simultaneously. Cooking the lentils required a cook's time for roughly half of the 50-minute cooking time. During the remaining time, the cook was free to perform other cooking steps. Next, the additional ingredients that would be added to the cooked lentils were prepared. For the mushroom burger, both mushrooms and onions needed to be cut and cooked. One whole pan of mushrooms and one whole pan of onions were required for each batch of mushroom burgers. A pan of mushrooms took about 10 minutes to cut and prepare for cooking. A pan of onions also took about 10 minutes to cut and prepare. For the cooking phase of this step, a cook placed both the pan of mushrooms and the pan of onions into the oven to broil at the same time. Mushrooms required six minutes of cooking, and onions required eight minutes. Therefore, the total time required to prepare the onions and mushrooms was the total setup time for both ingredients plus the longest cook time of either the mushrooms or the onions. There was only enough space in the oven for one pan of mushrooms and one pan of onions to be cooked simultaneously. Due to the short cooking times, a cook typically did not multitask process steps while the ingredients broiled. NoBull sold the four-packs of burgers to multiple channels including the Charlottesville City Market, the Charlottesville Whole Foods, Bodo's Bagels, and other local restaurants. While each channel had different costs and negotiated prices associated with it, the most common channels were wholesale (including local mom-and- pop stores, health food stores, and restaurants) and the Charlottesville City Market. For their analysis, the Raymonds assumed a four-pack of burgers currently sold for $6.00 and cost NoBull $4.50 to make. Of that cost, $2.50 was attributable to raw materials, and $2.00 was from labor, rent, and other miscellaneous costs. NoBull's kitchen operated five days per week for eight hours per day. Depending on the weekly demand, NoBull staffed the kitchen with from one to two cooks. At most, two cooks could t in the existing kitchen. The cooks were paid $12.00 an hour. Future Growth Strategy NoBull's current growth strategy was to continue to expand and establish its brand throughout Virginia and the DC area, targeting retailers and restaurants that were similar to its current customer base. NoBull decided to use its existing relationship with the Charlottesville Whole Foods to gain access to additional locations in Northern Virginia. The Raymonds reached out to the Northern Virginia Whole Foods regional manager, and five additional stores in the Northern VirginiaIDC area agreed to stock NoBull burgers. This would allow NoBull to test new markets and to see how well its product could penetrate a more metropolitan area. While accounting for only 3% of its sales in 2011, NoBull expected its sales to Whole Foods to grow to 9% of overall sales by the end of 2012 with this expansion. The company currently sold approximately 20 four- packs of burgers to the Charlottesville Whole Foods each week and estimated sales in each new 1Whole Foods store to be about half of that initially. Overall, the company expected total sales growth of 50% in 2012 over the previous year {Exhibit 4)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts