Question: Question One (10 Marks) With reference to the company in the case study, discuss possible ways to evaluate and select a supplier. Question Two (20

Question One (10 Marks)

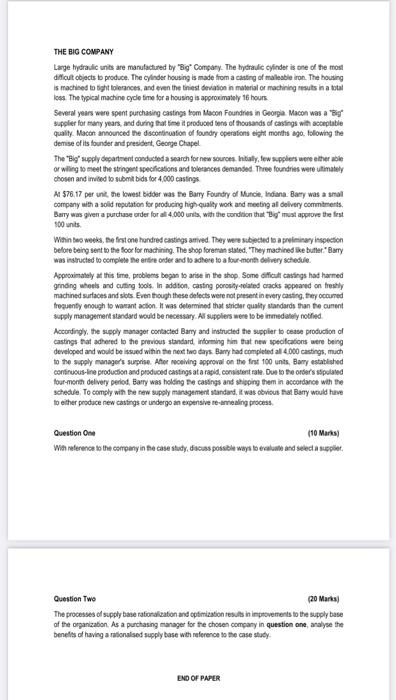

Question One (10 Marks)THE BIG CONPANY Large hiydaulic units are manufactured by "Big' Compacy. The hydralic cyfinder is one of the most dificult objects to produce. The cylinder housing is made from a caatiog of maleable iron. The housing is machised to tight tolerances, and even the thiest devason in maberial or machining resuts in a btal los4. The typical machine cycle tine for a housing is approeimalaly 16 hours. Several years were spent purchasing castings tom Macon Foundres in Ceonga. Macon was a "Big" suppler for many years, and dutng tha time il produced tots of thousands of caslings with acouptable qualty. Macon ansounced the disconfinuation of foundry operafons tight morths sgo. following the demise of its founder and presibert, George Chapel. The "Big" supply department conductod a search for new souroes. hitily, few supplens were either able or wiling to mest the itringet specilcations and bletances demanded. Thre foundries were utimatey chosen and imeted bo submit bids tor 4,000 castings A1 $76.17 par une, the lowest Bidder was fe Barry Foundry of Muncie, hofana. Bary was a sal company with a soldd repuation for producing high-qualiy work and meeting at delivery commirserts. Bary was given a purdase order for al 4,000 units, with the condition that 'Dg' musi appore the frest 000 inits. Watin two weeks, Bhe fint one hundred catings amtive. They were sabjected to a preiminay inpection belore being sent to the foor for mactiring. The shop foreman sasted. "They mactined ike bufler. "Bary was instructed to complowe the ertle orfer and to adhere to a four-month dotivery schedule. Acpocoimalely at this trme, problens bepho bo arise in the shop. Some Gificult casings had harned grinding whees and cutting bols. In addion, casting porosityqolatod concks appeave on fremhy machined surfaces and sibs. Even though these delects were not present in every casting, fey ocouned frequenty enough to wavant action. It was determined that stioler qualty tandards than foe cunent supply management t tendyd would be necessary. Al supplers wene is be immedaloly notfed. Aocondingly, the supply manager contacted Bany and instructed the syppler to cease production of castings fat adhered to the previous standard informing thin that new seollations were being developed and would be issued within the nect two days. Barry had completed al 4.000 castings, much to the spply manager's suprise. Ather nociving approval on the frat 100 unts. Bany established contrusur-ine producbon and pesduced castings at a rapid, consibent fate. Dun to ne onber's spelaled fourmsith delvery period, Eary was holding fe casings and stisping them in accordaroe wit the schedule. To comply with the new supply managemert itandard, if was obvisus hat Bary would have to either produce new castings or undergo an expensire te-tnnealing process. Question One (10 Marks) Wht referenos to the compeny in the case study, dicass possible wasi to eraluate and select a sucplet. Question Two (20 Marks) The processes di supply base rationaliation and opfimiaason tesults in inpocvements to the supply base of the orpankabion. As a purchasing manager for fe chosen company in question one, aralyse the benelfs of having a nabonalsed supply bose with referenoe to the case study

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts