Question: Question: Please note that this question has two parts (a and b). You may need to scroll the screen down, navigate left and right to

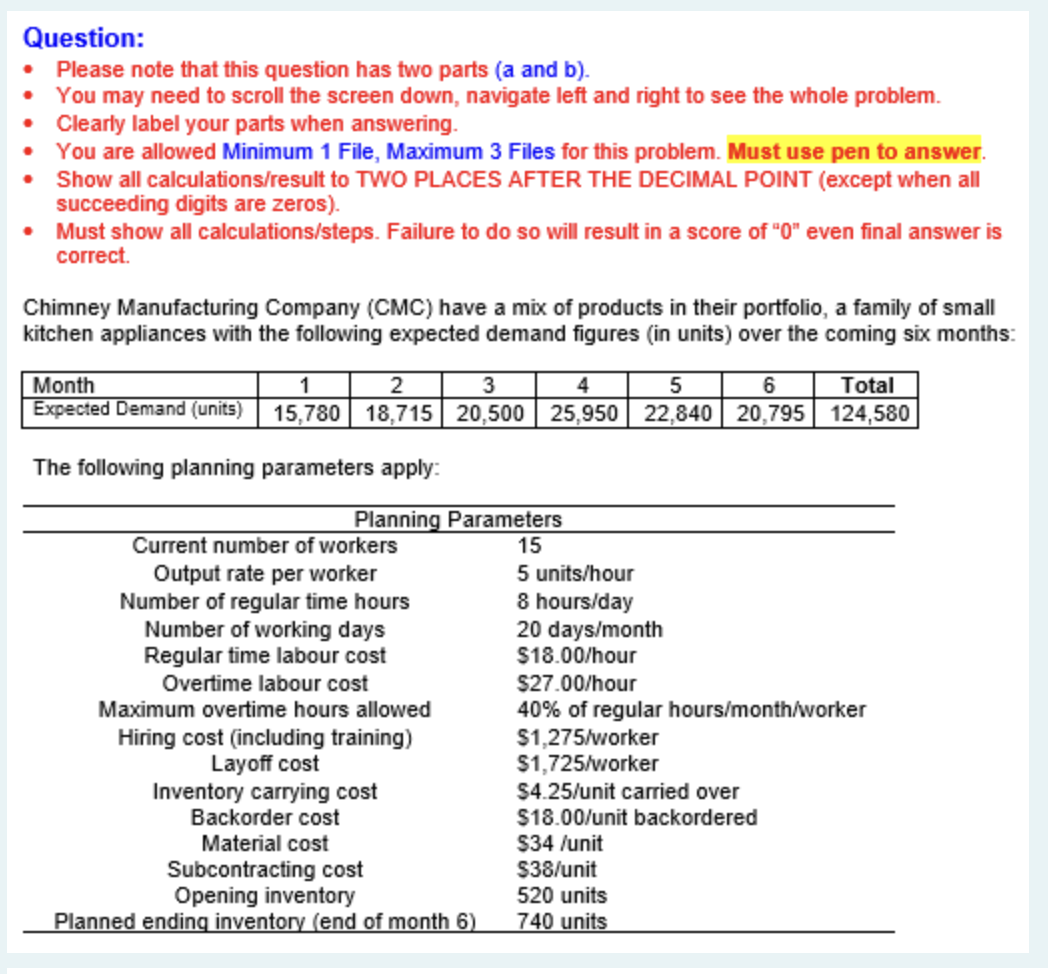

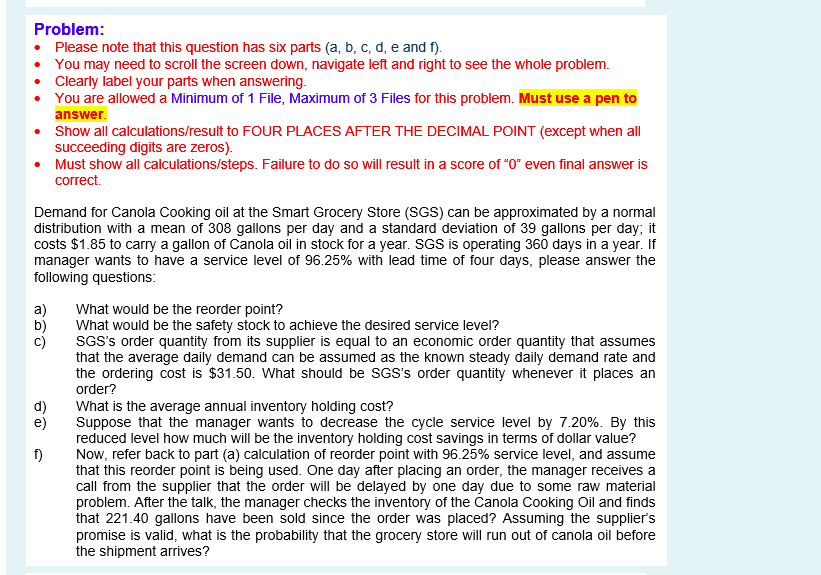

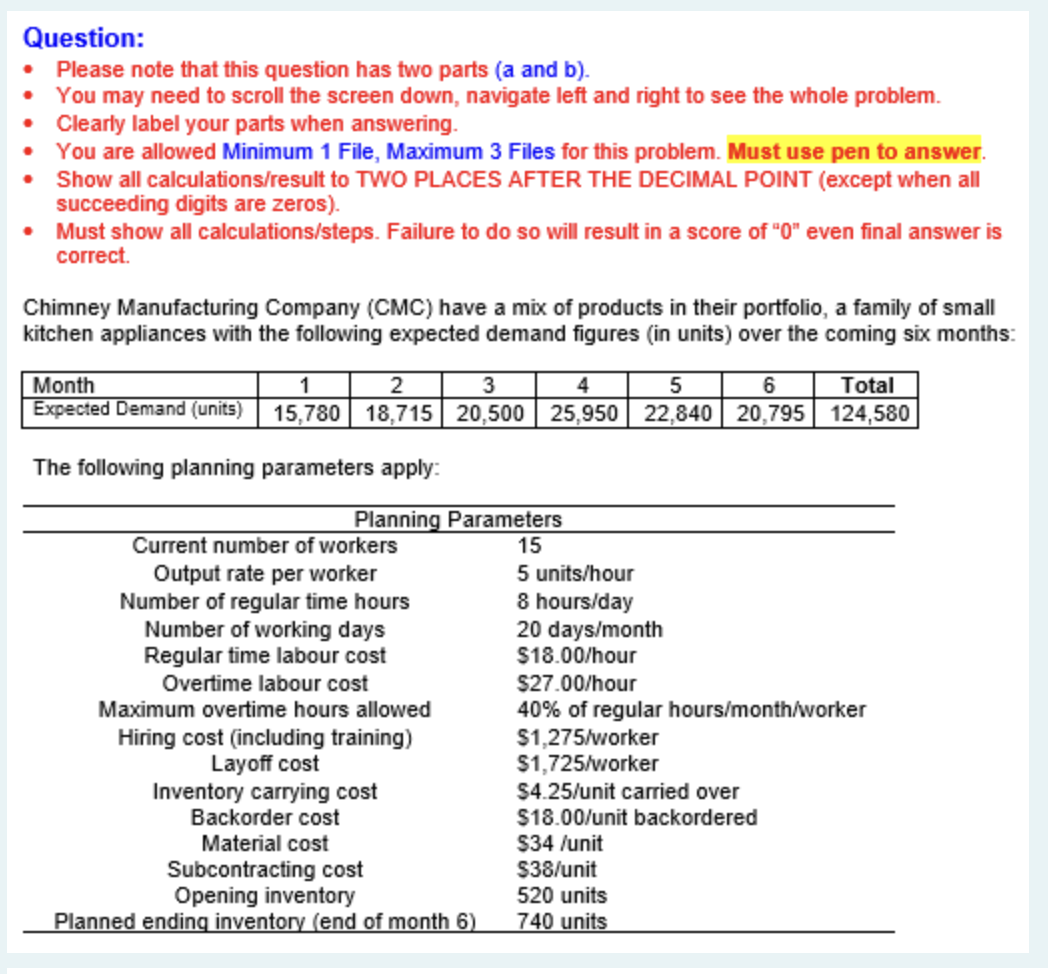

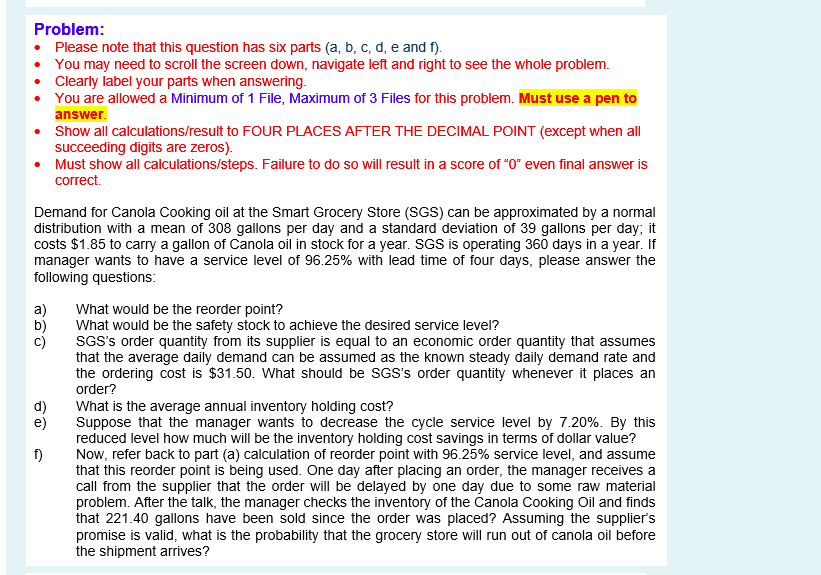

Question: Please note that this question has two parts (a and b). You may need to scroll the screen down, navigate left and right to see the whole problem. Clearly label your parts when answering. You are allowed Minimum 1 File, Maximum 3 Files for this problem. Must use pen to answer. Show all calculations/result to TWO PLACES AFTER THE DECIMAL POINT (except when all succeeding digits are zeros). Must show all calculations/steps. Failure to do so will result in a score of "0" even final answer is correct Chimney Manufacturing Company (CMC) have a mix of products in their portfolio, a family of small kitchen appliances with the following expected demand figures (in units) over the coming six months: Month Expected Demand (units) 1 15,780 2 3 18,715 20,500 4 5 6 Total 25,950 22,840 20,795 124,580 The following planning parameters apply: Planning Parameters Current number of workers 15 Output rate per worker 5 units/hour Number of regular time hours 8 hours/day Number of working days 20 days/month Regular time labour cost $18.00/hour Overtime labour cost $27.00/hour Maximum overtime hours allowed 40% of regular hours/month/worker Hiring cost (including training) $1,275/ worker Layoff cost $1,725/worker Inventory carrying cost $4.25/unit carried over Backorder cost $18.00/unit backordered Material cost $34 /unit Subcontracting cost $38/unit Opening inventory 520 units Planned ending inventory (end of month 6) 740 units Problem: Please note that this question has six parts (a, b, c, d, e and f). You may need to scroll the screen down, navigate left and right to see the whole problem. Clearly label your parts when answering. You are allowed a Minimum of 1 File, Maximum of 3 Files for this problem. Must use a pen to answer. Show all calculations/result to FOUR PLACES AFTER THE DECIMAL POINT (except when all succeeding digits are zeros). Must show all calculations/steps. Failure to do so will result in a score of "0" even final answer is correct Demand for Canola Cooking oil at the Smart Grocery Store (SGS) can be approximated by a normal distribution with a mean of 308 gallons per day and a standard deviation of 39 gallons per day, it costs $1.85 to carry a gallon of Canola oil in stock for a year. SGS is operating 360 days in a year. If manager wants to have a service level of 96.25% with lead time of four days, please answer the following questions: a) What would be the reorder point? b) What would be the safety stock to achieve the desired service level? c) SGS's order quantity from its supplier is equal to an economic order quantity that assumes that the average daily demand can be assumed as the known steady daily demand rate and the ordering cost is $31.50. What should be SGS's order quantity whenever it places an order? d) What is the average annual inventory holding cost? e) Suppose that the manager wants to decrease the cycle service level by 7.20%. By this reduced level how much will be the inventory holding cost savings in terms of dollar value? f) Now, refer back to part (a) calculation of reorder point with 96.25% service level, and assume that this reorder point is being used. One day after placing an order, the manager receives a call from the supplier that the order will be delayed by one day due to some raw material problem. After the talk, the manager checks the inventory of the Canola Cooking Oil and finds that 221.40 gallons have been sold since the order was placed? Assuming the supplier's promise is valid, what is the probability that the grocery store will run out of canola oil before the shipment arrives