Question: Question: Use the product information to develop an MRP here is the sample please do it in this form given blow. with what appears to

Question: Use the product information to develop an MRP here is the sample please do it in this form given blow.

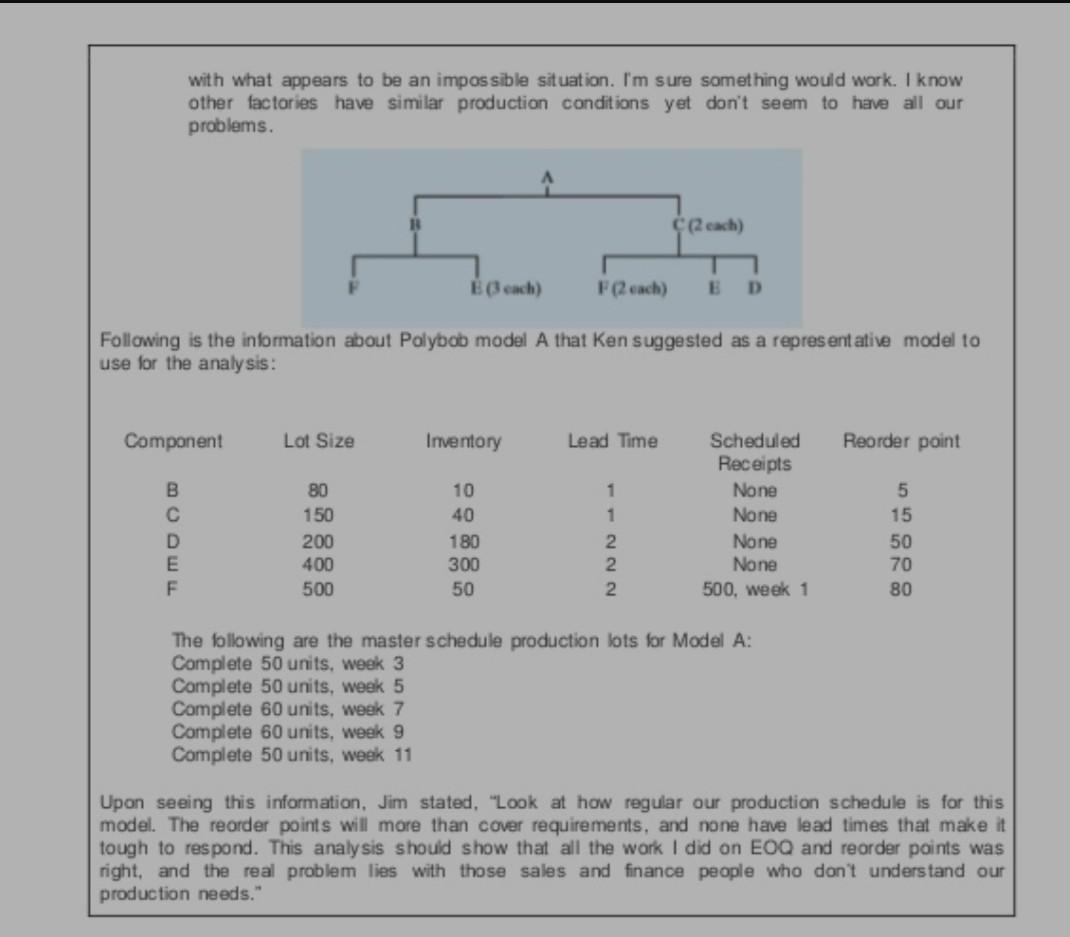

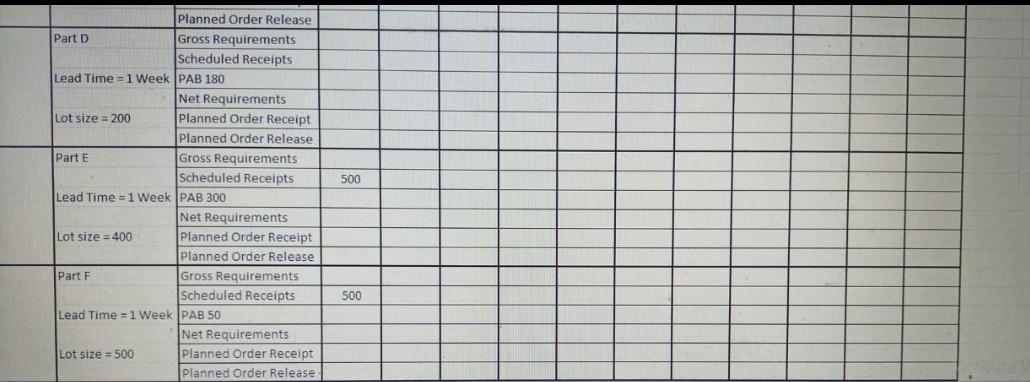

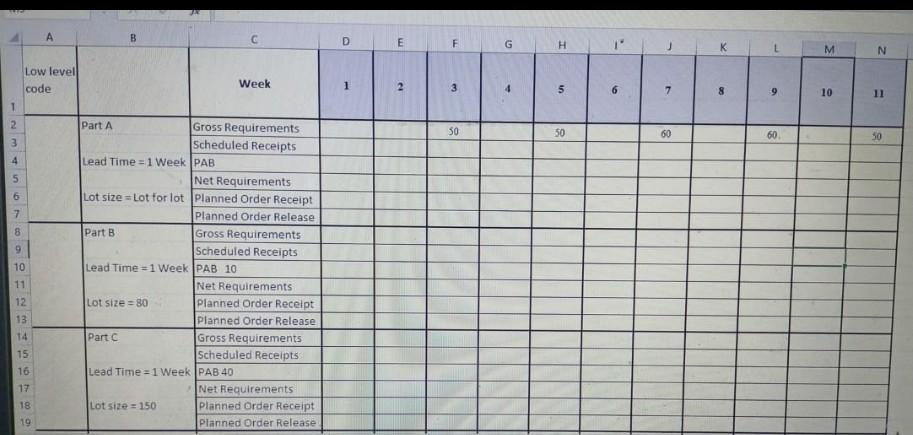

with what appears to be an impossible situation. I'm sure something would work. I know other factories have similar production conditions yet don't seem to have all our problems. C (each) E (each) F (2 each) ED Following is the information about Polybob model A that Ken suggested as a representative model to use for the analysis: Component Lot Size Inventory Lead Time Reorder point 10 40 1 1 B D E F 80 150 200 400 500 Scheduled Receipts None None None None 500, week 1 180 5 15 50 70 80 300 50 NNN The following are the master schedule production lots for Model A: Complete 50 units, week 3 Complete 50 units, week 5 Complete 60 units, week 7 Complete 60 units, week 9 Complete 50 units, week 11 Upon seeing this information, Jim stated, "Look at how regular our production schedule is for this model. The reorder points will more than cover requirements, and none have lead times that make it tough to respond. This analysis should show that all the work I did on EOQ and reorder points was right, and the real problem lies with those sales and finance people who don't understand our production needs." 500 Planned Order Release Part D Gross Requirements Scheduled Receipts Lead Time = 1 Week PAB 180 Net Requirements Lot size = 200 Planned Order Receipt Planned Order Release Part Gross Requirements Scheduled Receipts Lead Time = 1 Week PAB 300 Net Requirements Lot size = 400 Planned Order Receipt Planned Order Release Part F Gross Requirements Scheduled Receipts Lead Time = 1 Week PAB 50 Net Requirements Lot size = 500 Planned Order Receipt Planned Order Release 500 B D E F G H K L M N Low level code Week 1 2 2 3 5 6 7 en 8 9 10 11 1 2 3 So 50 60 60 50 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 Part A Gross Requirements Scheduled Receipts Lead Time = 1 Week PAB Net Requirements Lot size = Lot for lot Planned Order Receipt Planned Order Release Part B Gross Requirements Scheduled Receipts Lead Time 1 Week PAB 10 Net Requirements Lot size = 80 Planned Order Receipt Planned Order Release Part Gross Requirements Scheduled Receipts Lead Time = 1 Week PAB 40 Net Requirements Lot size = 150 Planned Order Receipt Planned Order Release

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts