Question: Questions 1. Develop a level production plan for Covolo Diving Gear. What are the advantages and disadvantages of this plan? Could Covolo implement a pure

Questions

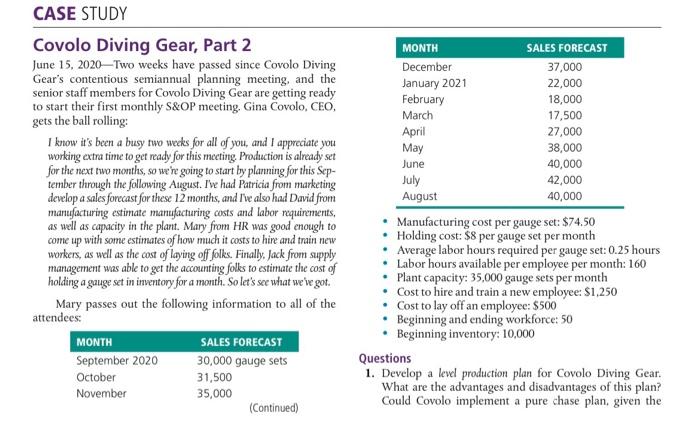

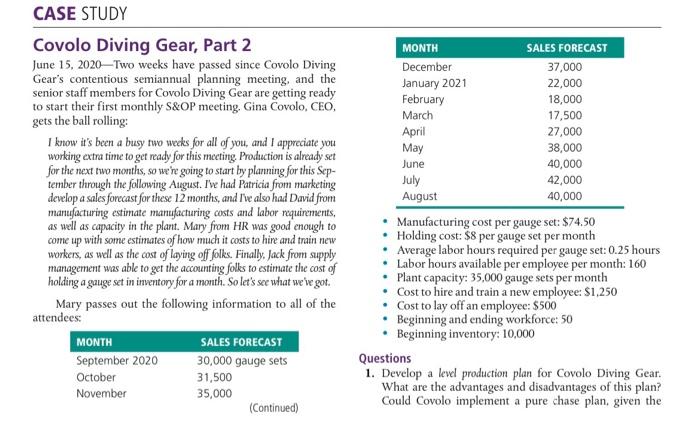

1. Develop a level production plan for Covolo Diving Gear. What are the advantages and disadvantages of this plan? Could Covolo implement a pure chase plan, given the current capacity? Why? If sales continue to grow, what are the implications for production capacity at Covolo?

2. Patricia Rodriguez, vice president of marketing, states, Ive got to tell you all that Im pretty comfortable with the forecasts for September through November, but after that, a lot could change. Its just very hard to forecast for four or more months out in this kind of market. How will a monthly S&OP update with rolling planning horizons help alleviate Patricias concerns? Are there still advantages to S&OP, even though the forecasts may change?

3. After looking over the level production plan, David Griffin, vice president of manufacturing, speaks up: This looks OK, but you know what bugs me about it? The assumption that if a worker is available, that worker has to be making gauge sets, even if we dont need any more. It might make sense in some cases to just have the worker not produce rather than lay off a worker in one month and hire someone else back the next. Do you agree? What are the holding costs asso- ciated with having an extra worker produce gauge sets for one month? How do these compare to the layoff and hiring costs? How might a strategy of keeping extra workers idle affect the estimated manufacturing costs for the gauge sets? (Hint: Labor costs have to be accounted for somewhere.)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock