Question: QUESTIONS: 1. What external and internal challenges was Jamil Akbar (the CEO) facing at AISL and why? 2. What is your analysis of the existing

QUESTIONS:

1. What external and internal challenges was Jamil Akbar (the CEO) facing at AISL and why?

2. What is your analysis of the existing culture within AISL?

3. Do you agree with Jamil that the safety requirements for AISL are too high and these IAEA safety policies and requirements are for Nuclear Power Plants and not for them?

4. What is your analysis of the cover-up of the staff radiation (overexposure) accident? What could have been done differently? Why?

5. What were the signs of normalization of deviance? Why no one observe and try to stop those deviances?

6. What is your analysis and assessment of the effectiveness of AISLs leadership and its safety culture?

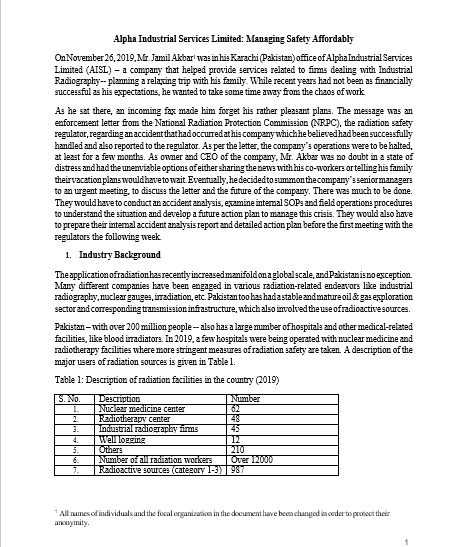

Alpha Industrial Services Limited: Managing Safety Affordably On November 26, 2019. Mr. Jamil Akbar' was in his Karachi (Pakistan) office of Alpha Industrial Services Limited (AISL) - a company that helped provide services related to firms dealing with Industrial Radiography--planning a relazzing trip with his family. While recent years had not been as financially successful as his expectations, he wanted to take some time away from the chaos of work As he sat there, an incoming fax made him forget his rather pleasant plans. The message was an enforcement letter from the National Radiation Protection Commission (NRPC), the radiation safety regulator, regarding an accident that had occurred at his company which he believedhad been successfully handled and also reported to the regulator. As per the letter, the company's operations were to be halted, at least for a few months. As over and CEO of the company, Mr. Akbar was no doubt in a state of distress and had the unenviable options of either sharing the news with his co-workers or telling his family their vacation plans wouldhave to wait. Eventually, he decided to summon the company's senior managers to an urgent meeting, to discuss the letter and the future of the company. There was much to be done. They would have to conduct an accident analysis, examine internal SOPs and field operation procedures to understand the situation and develop a future action plan to manage this crisis. They would also have to prepare their internal accident analysis report and detailed action plan before the first meeting with the regulators the following week 1. Industry Background The application ofradiation has recently increasedmimifoldon a globalacale, and Pakistanis no exception. Many different companies have been engaged in various radiation-related endeavors like industrial radiography, nuclear gauges, irradiation, etc. Pakistan too has hadastable and mature oil & gas exploration sector and corresponding transmission infrastructure, which also involved the use ofradioactive sources. Pakistan - with over 200 million people -- also has a large number of hospitals and other medical-related facilities, like blood irradiators. In 2019, a few hospitals were being operated with muclear medicine and radiotherapy facilities where more stringent measures of radiation safety are taken. A description of the major users of radiation sources is given in Table 1. Table 1: Description of radiation facilities in the country (2019) S. NO. Description Number 1. NUEST medicine center Radiotherapy center 48 3. Industrial radioraplay firms wel logging 12 5. Others 210 6. Number of all radiation workers Over 12000 7. Radioactive sources (category 1-39987 All names of individuals and the focal organization in the document have been changed in ceder to protect their muymity. Pakistan has seen till the recent past rather remarkable growth in its GDP, with an average of 5.5% per armum GDP growth rate during 2005-2015. This rapid expansion in the econoniy resulted in the development of new industrial products and services. However, recently the country's economic growth has faced a slow-down as well as foreign exchange shortages In 2010, the government decided to invest $15 billion into large construction projects with the help of intemational funding agencies to increase employment rates and accelerate the economic growth of the country 2. Industrial Radiography: Industrial radiography is an important application of radiation in which ionizing radiations are used to detect any cracks or hidden flaws in machinery and the like. A category-2 radioactive source is used in industrial radiography; ifnot used properly, it is capable of causing severe ham. such as bums. Usually, radioactive sources (like Ir-192). gamma camera projectors, guide tubes, crank cables, etc are all used to perfom a radiography job. It is mandatory to use safety gadgets like radiation survey meters, personal dosimeters, warrings signs and loudspeakers during thejob. 3. National Radiation Protection Commission (NRPC) Established in 2004 under the supervision of the Ministry of Science and Technology, the National Radiation Protection Commission (NRPC) is the main radiation safety regulatory body for the control of radiationrelated organizations in the country. TheNRPCperformsregulatory activities including granting authorization, performinginspections and enforcement, reviewing, assessing and developingregulations The NRPC expanded its role to include a culture of self-assessment on safety and staff training on leadership for safety. According to one of the senior regulators from the NRPC, they had been focusing their efforts on developing various regulations and SOPs to have a comprehensive regulatory framework. However, all regulatory activities were conducted as per international standards. To improve its quality of work, the NRPC invited the International Atomic Energy Agency (IAEA) to the country in 2013. Integrated Regulatory Review Service (IRRS) missions are used to review a country's regulatory practices in light of IAEA safety standards, thus providing an opportunity for a coumtry to discover areas of improvement. The IRRS mission to Pakistan performed a detailed review of various module: like licensing, inspections, regulatory framework review & assessment, occupational exposure, emergency preparedness, etc. The IAEA mission acknowledged the NRPC's well-developed systems. To ensure radiation safety under the regulations, the NRPC revised its documents to add that users of radiation sources would be required to prepare plans and procedures for radiation safety, transport, security, etc. Periodic inspections were conducted toverify regulation compliance by licensees like AISL. 4. Background of Company Alpha Industrial Services Limited (AISL) was set up in early 2007 and became a well-reputed company, Inown for its services related to industrial radiography (IR), and other bondestructive testing (techniques 2 used in material science and equipment industry to evaluate the properties of a material component or a system without causing any physical damage). The company used to provide services not only at muclear plant sites but also at pipelines in remote areas throughout the country. An organogram and full details of the management of employees are given in Exhibit 1 and Exhibit 2, respectively 5. Challenges for AISL since 2015 Due to intense competition in the radiography services industry and the devaluation of the rupee in 2015, it was becoming increasingly challenging for the company to maintain ita quality of services with the existing cost structure. In addition to this, costs such as the price of radioactive sources calibration of equipment, transport and other charges, ets -- had also increased considerably (a 40% increase in the previous year). Meanwhile in 2016, due to the changes in the regulatory commission act, the licensing fee had nearly doubled and new regulatory and safety requirements for licensees had also been implemented. The new safety and security requirements that had been introduced by the IAEA safety standards were also imposed more strictly, including stafftraining, staffrequirements during a shift, and the management and leadership for safety procedures and policies, security of the sources, etc. 6. Changes to Business Process Due to these and related factors, AISL profits were facing asteep decline since 2017. Many clients of AISL had informed Mr. Akbar that the company's prices were higher than its competitors, and if the pricing was not adjusted, they would have to shift their business to AISL's competitors Mr. Jamil Akbar had shared these comcems with his mmagement team during the company's annual strategic meeting in March 2018. In early 2018, to manage the high costs of operations, the company also reduced its fixed cost and laid off 20% of its workforce, reducing its numbers from about 80 workers to under 65 workers. The workers released from the company included but were not limited to the Director Operations), radiography workers, a few staff members from finance department and members of the HR department The company also adopted a new policy of allocating two technical personnel for a radiography source instead of the previous practice of three technical persons per radiography source. While the policy of three persons per radiography operation was considered a 'good practice', the two-person policy fulfilled the minimal requirements for workforce availability at site radiography activities. 7. Adjustment to Changes in Policy The new operational policy went well without any incident and employees adjusted to the situztion accordingly. Due to the smaller number of trained workers, there was an indication of an increase in personal radiation doses in the first few months but since these personal radiation doses were still well below the regulatory limits, the shift supervisors or senior manager in fact, the company -- did not pay much attention to this issue. The average radiation dose per worker was 8.4 m. Sy for the year 2018 in comparison with 6.7mSv per year for the three years before that with the same volume of radiation work, which indicated a decline in occupational radiation Safety (TAE. , 2013). Mr. Sadiq Khan, the Radiation Protection Officer (RPO) responsible for all the technicaljobs, was slightly concerned about this increase in radiation dose and reported this trend to Mr. Akbar the CEO, and Mr. Adeel Ahmed, Director Technical. Mr. Akbar suggested Mr. Khan ingese workers' incentives if they worked extra shifts to compensate them for their extra efforts. February 6, 2019 Mr. Khan informed the regulator during the inspection of the company office that one radiation worker received & Svin six months, which was higher than his previous dose record for the same duration Mr. Ahmed, the technical director, felt that this dose was still under the regulatory limits and after the specific radiographer had undergone proper training be could still perfom his job as needed. An inspector of the regulatory body observed (Exhibit 3) the record of radiation doses during the inspection but noted no violation of regulatory requirements because the dose was still under the limits. However, the inspector indicated his observation during his discussions with Mr. Khan, and asked hims to report back any further increase in the dose, or any other incident to the NRPC without any delay. Mr. Khan promised to comply with said advice. The inspector further said to Mr. Kham: "It seems your senior management does not understand radiztion safety and does not give respect to the regulations and safety protocol They have been ignoring our feedback, and signs of decliningsafety in your organization again and again". Mr. Khan did not respond to this observation by the inspector. February 22, 2019 In a particular event, on 22 Feb 2019, the company radiography team was engaged in an operation in a remote area outside the city. The team -- one radiographer and one technical assistant (TA) -- finished a long day's work at the power plant and was traveling to another location for another radiography job. The vehicle ended up malfunctioning on the way back to the city at midnight. One of the team members was driving the vehicle and knew very little about how to repair the vehicle's engine. He opened the back door of the vehicle, removed some necessary equipment from the rear cabin for the maintenance of the vekicle and quickly did therepairs, and thejourneyresumed Beforereaching theradiographysite, theradiographer checked the reading on the radiation survey meter and discovered that the projector (the radioactive Source) was not present in the vehicle. He immediately realized that the projector must have fallen out of the vehicle because the back door had not been properly fastened after the maintenance stop. The team started searching for the projector alongside the road. Meanwhile, a shopkeeper contacted the radiographer on his mobile phone and informed him that the container was in his custody because a phone number was pasted on the source container box Consequently, the projector was recovered from the shopkeeper. The team performed a detailed radiation survey and verification of source from its pigtail number. Fortunately, everything was found unharmed, with no damage caused to the physical condition of the source container The matter was brought to the attention of the company's management and the regulatory body. The company's management took action and suspended the involved workers for two months immediately. This action was also reported to the NRDC, which also conducted a special inspection and instructed the company to improve their safety and security standards and SOP, because as per IAEA.security standards the ease of handling of these devices and their presence in vehicles outside secured facilities make them vulnerable to unauthorized removal (IAEA, 2009, 2019). The company's management felt annoyed with the recommendations and involvement of the regulatory body (mentioned in exhibit 4). Mr. Akbar and Mr. Almed believed that since no radiation exposure had been caused to the public or the radiation workers and everything had turned out fine at the end, there was no need for any extra regulatory actions. In an internal meeting with RPO Mr. Khan and other technical field staff, Mr. Akbar and Mr. Ahmed decided not to report small incidents to the NRPC in the future. Mr. Akbar told his staff in a meeting that they would need to be more careful, keep such incidents to themselves and not share imowledge of mistakes with others. No one in the meeting, including Mr. Khan, voiced zmy disagreements with the CEO's comments and they all agreed to be more careful next time. The meeting ended in 10 short minutes without much discussion Three months later, the company signed a large contract with a pipeline company, the services included performing industrial radiography in remote areas. The contract was tightly scheduled and complicated due to many activities in different locations in parallel. However, the benefits of an advantageous contract kept everyone happy April 26, 2019 On this day, there was a customer complaint about the behavior of Mr. Shabbir (the Radiographer). He had been at a job at a site that was located outside the city and had come backrelatively late. While he had been on his way back, the customer had called Mr. Khan and informed him that Mr. Shabbir's behavior had been professional. The customer told the RPO that the way Mr. Shabbir had been handling radioactive sources seemed unsafe, and when a member of the customer's team had highlighted this to Mr. Shabbir. be had responded harshly and argued with the employee Mr. Khan was concemed about this issue as the customer had been an important one for the fim, and a bad experience with AISL could lead the customer away from them and towards their competitors. As a result, Mr. Khan called Mr. Shabbirto a meeting the next day and toldhim about the customer's complaint. Mr. Shabbir placed the entire blame on the customer, but Mr. Khan reminded him of the importance of keeping customers satisfied. Having made sure the message had been delivered to Mr Shabbir. Nir Khan did not pursue the matter further and did not consider it necessary to inform Mr. Akbar. Later in the day. Mr. Shabbit was found grumbling to his fellow employees about how Mr. Khan was disconnected from the ground realities of their work. November 5, 2019 On this day, two radiography jobs were scheduled at two different locations (A and B) some 100 km apart from each other. The company decided to use a single team of two persons with a high activity radioactive source (Ir-192,80 Curie) to perform both jobs. Mr. Khan was a bit cautious due to the high activity and briefed the team accordingly.He instructed the team --Mr Shabbit (radiographer) and Mir Haris(technical assistant) -- to conduct the first job early in the moming and the second job in the evening of the same day and then retum to the city office where the source storage pit was located. In doing so, he planned to save the cost of an overight stay at Site B. He further instructed the team to use an old and repaired guide tube and gamma camera projector instead of the new one, which he planned to use for another job at a different plant site due to its stricter quality control measure by the other plant management. The new items and the old items can be seen in the following figures: 5 The team left the city office early in the moming for the radiography job at Site A They had decided that one person would do the job so that the second team member could rest during their break. The job was completed in five hours, as per schedule. The gamma camera and the guide tube did not cause any problems during the work at Site A. During the joumey to Site B, the team got stuck on the highway in traffic congestion, with trucks, buses and cars stuck in the traffic jam, caused loy an accident Affer spending some two hours stuck in the traffic chaos, the team's joumey to Site B was also slower than expected, which further delayed their arrival. One of the team members even mentioned that on a good day the second job would have been done by another team or on the next day but the prevailing financial crunch forces us to do both jobs without any rest". So the team had to perform bothradiography jobs on the same day and retum on the same long, exhausting day. The team anrived at Site B a little later in the evening, had a quick meal and started with its work. They completed their job before midnight. Exhausted from the two consecutive radiography jobs and the long joumey, they tried to spend the night at the site but there were no prior arrangements for their stay and for source storage. Furthermore, they tried to call Mr. Khan, the RPO, who did not answer their calls because of the late hour. Disappointed with the situation the team decided to return to the city office late at night. They quickly assembled their material and put it all in the vehicle during the hurry to place things in the car they missed out on performing a final survey to ensure that the highly active radioactive source was intact in the shielded gamma projector. The source could not be retrieved from the projector and was still in the guide tube, in an exposed position The team placed all their material inside the vehicle and drove to the city ima 3.5-hour joumey. When the team reached the city office pit at 6:00 am the next moming, they realized that the source was not in the gamma projector. Mr. Shabbir, the radiographer, turned on the survey meter which showed a very high radiation reading, indicating that the source was unshielded. Realizing the gravity of the situation, and worried about the high radiation level, they quickly placed all the stuff inside the storage room and informed Mr. Khan and the guard on duty. Mr. Khan responded to their urgent call and reached the office within the next 30 minutes, and restored the source from the guide tube to the gamma projector. He used only the active dosimeter to avoid excessive radiation dose to the passive dosimeters. In the moming, the matter was brought to the knowledge of Nir. Akbar (the CEO) and Mr. Ahmed (the technical director). They decided that since the source was intact, there was no need to inform the NRDC. Since Mr. Khan did not use dosimeters, there was no chance of my overexposure for him. They further decided to pretend that the dosimeters of the two working radiographers had been lost during the long joumey and their recovery was not possible, since they had no way of knowing their exact location Mr. Akbar and Mr. Ahmed thus decided to cover up this dangerous incident. The two potentially overexposed persons (Mr. Shabbir and Mr. Haris) were told in their brief that the event took place entirely due to their mistake. To avoid any further penalties, they were instructed to stay silent. The company gave them leave until further instructions and paid them enough for better food and medical treatment if needed. A short while later, Mr Haris started to feel nauseous, followed by vomiting and a severe headache. Mir Shabbir developed the same condition. They both contacted the company and were provided some help, but they wanted access to better medical care which AISL declined due to financial reasons Annoyed with the situation, Mr. Shabbir zent an anonymous letter (Exhibit 5) to the NRDC regarding the working conditions at AISL. To conduct an accurate investigation and obtain firsthand information, the 7 inspectors of the NRPC approached the affected radiographers instead of the company or Mr. Khan (RPO). After obtaining the initial information and the assessment of the dose the workers had the NRPC initiated a detailed investigation and enforced action against AISL. 8. Company's View and Actions about New Regulatory Requirements Mr. Akbar, Mr. Ahmed and Mr. Ali (AISL's director of finance) felt that apart som necessary regulatory requirements like detection equipment, personal dosimeters, transport vehicle, health surveillance, etc mary of the other regulatory requirements were merely a fonality and did not contribute to improving a culture of safety for company personnel These additional operating requirements included having a well- established management system, a positive safety culture in the organization, leadership for safety, and independent safety assessments in the organization, etc. Mr. Akbar and his senior management team thought that these requirements were similar to IAEA standards and should apply only to the nuclear power industry instead of all radioactive sources. The NRPC inspectors, though, were urging AISL to conduct safety culture self assessments and have integrated safety management systems along with other strict requirements of radiation safety like equipment, calibration, dosimetry, etc. Mr. Akbar and Mr. Ahmed believed that they should not be subject to these high safety requirements since they had never had an accident in the company before As per Mr. Akbar, "We don't have as many safety risks for [the] public as nuclear power plants do, so why should we be following the same policies and procedures?" The company did not follow the recommendations on safety culture and SOP: by the NRPC safety documents. The repair & maintenance policy was also restricted to the most important itenis and preventive maintenance activities were exercised rarely to reduce the overall cost. 9. The Final Actions and the Urgent Meeting After conducting sufficient investigation, the NRPC sent a letter (Exhibit 6) to the CEO, Mr. Akbar, asking him to halt allradiographyrelated activities and provide further details on the incident. Onreceiving the letter, the CEO called an office meeting to discuss this occurrence with his whole team He started to think about the crises his company had been facing during the last two years. He started to reflect on the decisions he had taken to save the company from financial disaster Perhaps Mr. Akbar was wondering how those actions may have influenced the safety behavior of his team. For example, why did the lower operation staff demonstrate such negligence? Why these mistakes? Why had no one in his team raised any issues regarding safety? What could he do to fix this? Mr. Akbar was very disappointed in his team and just could not understand why the operational staff was this negligent. He wondered what he could do to make sure that such negligence did not occur in the future. Should he fire the operational staff responsible for the mishap? This would help him get rid of the problematic staff members, and also send a strong message to other staff members to be more careful He also wanted to penalize his management team for not identifying the problems earlier At the same time, the CEO thought that such small incidents were fairly common in large technical organizations, but he knew that this would not satisfy the NRPC inspectors. With all this in mind, he began the meeting with senior staff members 8Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts