Question: Questions 32-35 Please read the below mini case carefully and answer questions. MedCan Medical Solutions Company has been informed by their supplier that they anticipate

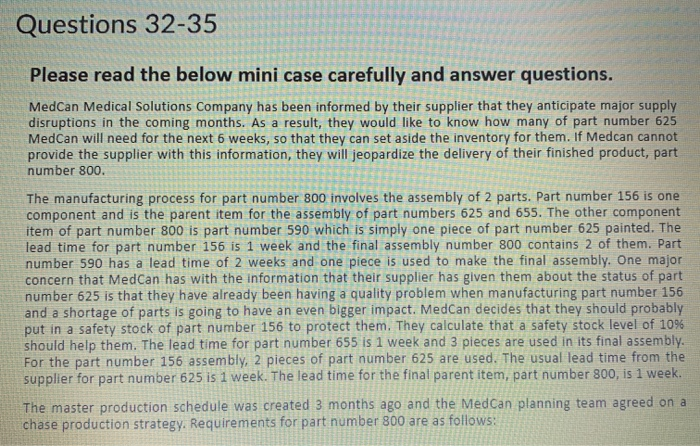

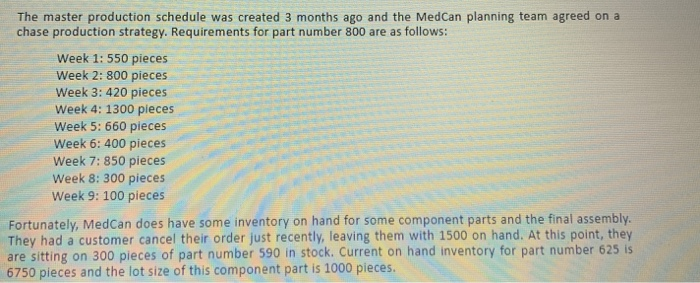

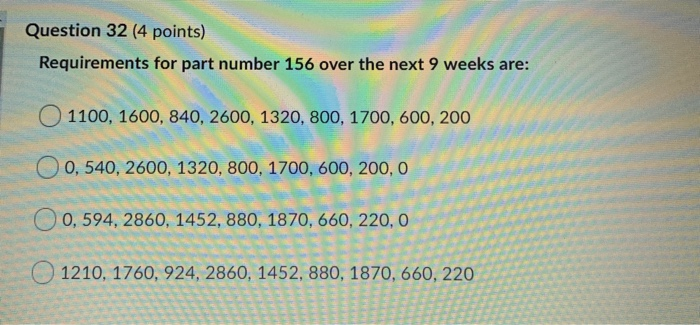

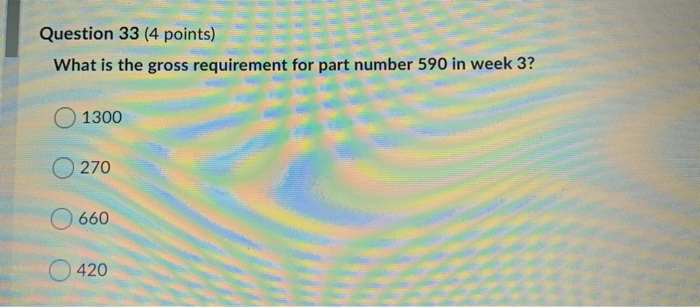

Questions 32-35 Please read the below mini case carefully and answer questions. MedCan Medical Solutions Company has been informed by their supplier that they anticipate major supply disruptions in the coming months. As a result, they would like to know how many of part number 625 MedCan will need for the next 6 weeks, so that they can set aside the inventory for them. If Medcan cannot provide the supplier with this information, they will jeopardize the delivery of their finished product, part number 800. The manufacturing process for part number 800 involves the assembly of 2 parts. Part number 156 is one component and is the parent item for the assembly of part numbers 625 and 655. The other component item of part number 800 is part number 590 which is simply one piece of part number 625 painted. The lead time for part number 156 is 1 week and the final assembly number 800 contains 2 of them. Part number 590 has a lead time of 2 weeks and one piece is used to make the final assembly. One major concern that MedCan has with the information that their supplier has given them about the status of part number 625 is that they have already been having a quality problem when manufacturing part number 156 and a shortage of parts is going to have an even bigger impact. MedCan decides that they should probably put in a safety stock of part number 156 to protect them. They calculate that a safety stock level of 10% should help them. The lead time for part number 655 is 1 week and 3 pieces are used in its final assembly. For the part number 156 assembly, 2 pieces of part number 625 are used. The usual lead time from the supplier for part number 625 is 1 week. The lead time for the final parent item, part number 800, is 1 week. The master production schedule was created 3 months ago and the MedCan planning team agreed on a chase production strategy. Requirements for part number 800 are as follows: The master production schedule was created 3 months ago and the MedCan planning team agreed on a chase production strategy. Requirements for part number 800 are as follows: Week 1: 550 pieces Week 2: 800 pieces Week 3: 420 pieces Week 4: 1300 pieces Week 5: 660 pieces Week 6: 400 pieces Week 7: 850 pieces Week 8: 300 pieces Week 9: 100 pieces Fortunately, MedCan does have some inventory on hand for some component parts and the final assembly. They had a customer cancel their order just recently, leaving them with 1500 on hand. At this point, they are sitting on 300 pieces of part number 590 in stock. Current on hand inventory for part number 625 is 6750 pieces and the lot size of this component part is 1000 pieces. Question 32 (4 points) Requirements for part number 156 over the next 9 weeks are: 01100, 1600, 840, 2600, 1320, 800, 1700, 600, 200 0, 540, 2600, 1320, 800, 1700, 600, 200, 0 O 0,594, 2860, 1452, 880, 1870, 660, 220, 0 O 1210, 1760, 924, 2860, 1452, 880, 1870, 660, 220 Question 33 (4 points) What is the gross requirement for part number 590 in week 3? O 1300 O 270 O 660 420 Question 34 (4 points) What is the projected on-hand inventory for part number 625 in week 4? 998 578 850 50 Question 35 (4 points) How many of part number 625 MedCan Medical Solutions Company will need to buy from their supplier over the next 6 weeks? 1000, 5000, 4000, 2000, 3000, 1000 2000, 3000, 2000, 4000, 1000, 1000 3000, 3000, 3000, 4000, 1000,0 O 0.0, 1000, 1000, 1000, 2000 Previous Page Page 24 of 24 Questions 32-35 Please read the below mini case carefully and answer questions. MedCan Medical Solutions Company has been informed by their supplier that they anticipate major supply disruptions in the coming months. As a result, they would like to know how many of part number 625 MedCan will need for the next 6 weeks, so that they can set aside the inventory for them. If Medcan cannot provide the supplier with this information, they will jeopardize the delivery of their finished product, part number 800. The manufacturing process for part number 800 involves the assembly of 2 parts. Part number 156 is one component and is the parent item for the assembly of part numbers 625 and 655. The other component item of part number 800 is part number 590 which is simply one piece of part number 625 painted. The lead time for part number 156 is 1 week and the final assembly number 800 contains 2 of them. Part number 590 has a lead time of 2 weeks and one piece is used to make the final assembly. One major concern that MedCan has with the information that their supplier has given them about the status of part number 625 is that they have already been having a quality problem when manufacturing part number 156 and a shortage of parts is going to have an even bigger impact. MedCan decides that they should probably put in a safety stock of part number 156 to protect them. They calculate that a safety stock level of 10% should help them. The lead time for part number 655 is 1 week and 3 pieces are used in its final assembly. For the part number 156 assembly, 2 pieces of part number 625 are used. The usual lead time from the supplier for part number 625 is 1 week. The lead time for the final parent item, part number 800, is 1 week. The master production schedule was created 3 months ago and the MedCan planning team agreed on a chase production strategy. Requirements for part number 800 are as follows: The master production schedule was created 3 months ago and the MedCan planning team agreed on a chase production strategy. Requirements for part number 800 are as follows: Week 1: 550 pieces Week 2: 800 pieces Week 3: 420 pieces Week 4: 1300 pieces Week 5: 660 pieces Week 6: 400 pieces Week 7: 850 pieces Week 8: 300 pieces Week 9: 100 pieces Fortunately, MedCan does have some inventory on hand for some component parts and the final assembly. They had a customer cancel their order just recently, leaving them with 1500 on hand. At this point, they are sitting on 300 pieces of part number 590 in stock. Current on hand inventory for part number 625 is 6750 pieces and the lot size of this component part is 1000 pieces. Question 32 (4 points) Requirements for part number 156 over the next 9 weeks are: 01100, 1600, 840, 2600, 1320, 800, 1700, 600, 200 0, 540, 2600, 1320, 800, 1700, 600, 200, 0 O 0,594, 2860, 1452, 880, 1870, 660, 220, 0 O 1210, 1760, 924, 2860, 1452, 880, 1870, 660, 220 Question 33 (4 points) What is the gross requirement for part number 590 in week 3? O 1300 O 270 O 660 420 Question 34 (4 points) What is the projected on-hand inventory for part number 625 in week 4? 998 578 850 50 Question 35 (4 points) How many of part number 625 MedCan Medical Solutions Company will need to buy from their supplier over the next 6 weeks? 1000, 5000, 4000, 2000, 3000, 1000 2000, 3000, 2000, 4000, 1000, 1000 3000, 3000, 3000, 4000, 1000,0 O 0.0, 1000, 1000, 1000, 2000 Previous Page Page 24 of 24

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts