Question: READ CASE-28 and answer question -4 CASE 28 Peas 31 of 42 Case date 1995 Stuart Chambers and Tammy Helander Introduction John Lincoln nodded goodbye

READ CASE-28 and answer question -4

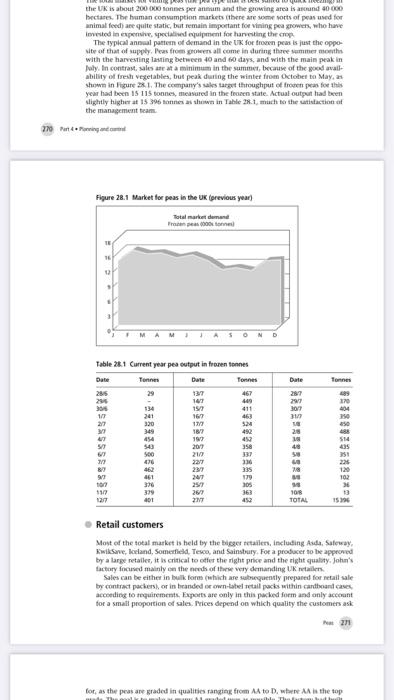

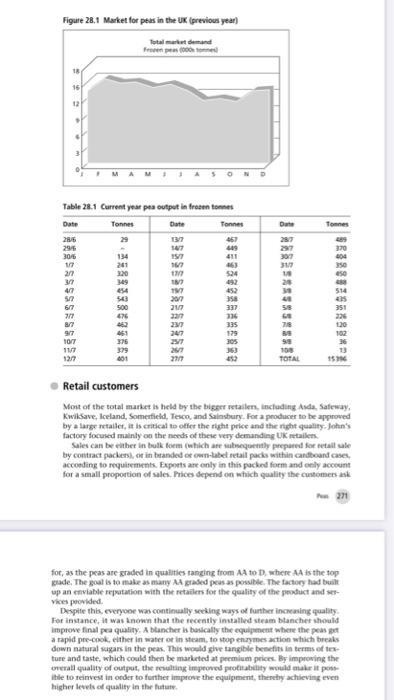

CASE 28 Peas 31 of 42 Case date 1995 Stuart Chambers and Tammy Helander Introduction John Lincoln nodded goodbye to the guard and drove out of the gates of his targe factory, situated in a fertile coastal region of eastern England. He drone home through a soft rolling landscape, surrounded by shimmering green fields towards a darkening early September sky, but the sight of this beautiful summer scene save him little peace of mind. It just made him worry more about peas and pea fields Peas that had to be harvested, Transported to the factory, chanel process from and packaged And soon plans had to be completed for next your peacrop, because - Factory Manager, he had tokok ahead to ensure that all the production process would be prepared to cope with the requirements of the increasingly demanding customers This year had been difficult. The weather had been exceptionally good, which meant that the harvesting period had been much shorter than malputtinger sure on the factory, which only had a limited daily processing capacity. The factory was designed to produce a range of from vegetables including care cauliflower beans, peas, petit pois, broccoli, and sprouts. It belonged to a large specialist food group, and had an enviable reputation for its high quality standarch Despite John's many years of production management experience, the pea pro Cewing operation had always been his peatest headache during the summer season The previous year had turned out to be an exceptionally long harvesting period of 65 days, which was relatively easy to cope with. However, this year season because of the fine weather, had shrunk to a more normal 1 days, which had mantan immense pressure in getting about the same tonage of peas through the factory in the much shorter period. Tean always caused the worst problems they wete by far the largest crop handled by the factory, and had to be processed in a very short time after being picked John had discussed many times with the Crop Planning Manager, Dave Monson. the possibility of extending the pea growing ason to lessen the pressure on the factory but it was difficult to make any further changes. As Elave explained Well, untortunately you can't plan the weather! Certainly, we do influence when the De should be ready for vining packing by using the best powible planning to ensure that the harvest & spread out over as long a time as possible. You know as well as ido. that the distribution of harvest times can be manipulated for emple, by wing wlected south and north facing fields, different varieties of seed, and planting at different altitudes above sea level. We have continuously worked to make this planning better 269 and to have better cooperation with the grower. We have managed to get them to agree on a target growing plan period of 44 days instead of 36. which is the normal con tract period for growers supplying other factories. But there is a limit in how much we can extend the season-the peas will simply not grow over a longer period, and I believe we have reached the limit. The yield are alio different, depending on the harvesting period. For the first and last quarter of the period the yield is only around 35 tonnes per hectare, whereas in the middle the yield is as much as six tonnes per hectare. The grow ers are naturally more interested in having their main harvest in the middle,tor obvious economice It was only two weeks after the last of this year's harvest had gone through the factory, and the group's operations director had scheduled the following Wednesday to meet with John and the management team. They would go through this year's output figures compared to targets. Each year's targets were set on how many tonnes of frozen peas they would have to produce to satisfy anticipated customer demand The company Although the frozen vegetable business had achieved only slow organic growth. It had continued to invest in improved processing facilities, and to develop better product quality through agricultural technology and practices as well as wine ca the UK is about 200 000 tonnes per annum and the growing area is around 10000 hectares. The human consumption markets there are some sorts of peas used for animal feeds are quite static, but remain important for vining pea growers who have Invested in speciale pent for any in the The typical annual pattern of demand in the UK for froen peas is just the oppo site of that of supply Peas from groen all come in during the summer month with the harvesting lasting between 40 and 60 days, and with the main peak in July. In contrast, sales are at a minimum in the summer, because of the good avail- ability of fresh vegetables, but peak during the winter from Octobetto May, as shown in Figure 28.1. The company's sales target throughput of frozen peas for this year had been is 11 tonnes, measured in the frozen state. Actual output had been slightly higher at 15 396 tonnes as thwn in Table 28.1, much to the station of the management team 770 Figure 28.1 Market for peas in the UK (previous your) Total market demand TE 16 Date Tonnes 189 170 404 Table 2.1 Current year pea output in trozen tonnes Tonnes Date Tonnes 235 29 1377 25 300 157 411 177 241 16 463 22 320 17 524 349 167 492 454 192 452 2012 358 500 210 337 777 2277 236 237 335 461 2T 179 376 257 110 205 379 363 29 30/7 31 28 90 488 514 435 120 102 13 22 1018 TOTAL Retail customers Most of the total market is held by the bigger retailers, including Asda Sateway Kwikave, keland, Somer. Tesco, and Sainsbury. For a producer to be approved by a large retailer, it is critical to offer the right price and the right quality. John's factory focused mainly on the needs of the very demanding UK retailers Sales can be either in bulk form which are subsequently prepared for retail sale by contract packers, or in handed or own-tatel retail packs within cardboard cases, according to requirements. Exports are only in this packed form and only account for a small proportion of sales. Prices depend on which quality the customers ask for, as the peas are graded in qualities ranging from A to where is the top Figure 28,1 Market for peas in the UK (previous year) 16 Tones 370 307 30 Table 28.1 Current year pea output in frasen tonnes Date Tonnes Date Tonnes 286 467 296 3076 134 197 411 21 30 349 492 40 57 2017 358 677 500 21 337 777 476 336 87 335 977 241 179 107 376 21 117 514 351 224 120 102 100 TOTAL Retail customers Most of the total market is held by the bigger retailers, including Anda. Safeway, KwikSave, Keland, Somerfield, Tesco, and Sainsbury. For a producer to be approved by a large retailer, it is critical to offer the right price and the night quality John's factory focused mainly on the needs of these very demanding UK talen Sales can be either in bulk form (which are sequently prepared for retail sale by contract packers, or in branded crown-label retail packs within cardboard cases, according to requirements. Exports are only in this packed form and only account for a small proportion of sales. Prices depend on which quality the customers ask fot, as the peas are graded in qualities tanging from A to D, where is the top prade. The goal is to make as many AA grade peus as possible. The factory had built up an enviable reputation with the retailers for the quality of the product and se vices provided Despite this everyone was continually seeking ways of further increasing quality For instance, it was known that the recently installed steam blanchet should improve final pea quality. A blancher is basically the equipment where the peas get a rapid pre-cook, either in water or in steam, to stop enzymes action which breaks down natural sugars in the peas. This would give tangible benefits in terms of te ture and taste, which could then be marketed at premium prices. By improving the orerall quality of output, the resulting improved profitability would make it poss ible to invest in order to further improve the equipment, thereby achieving even higher levels of quality in the future CASE 28 Peas 31 of 42 Case date 1995 Stuart Chambers and Tammy Helander Introduction John Lincoln nodded goodbye to the guard and drove out of the gates of his targe factory, situated in a fertile coastal region of eastern England. He drone home through a soft rolling landscape, surrounded by shimmering green fields towards a darkening early September sky, but the sight of this beautiful summer scene save him little peace of mind. It just made him worry more about peas and pea fields Peas that had to be harvested, Transported to the factory, chanel process from and packaged And soon plans had to be completed for next your peacrop, because - Factory Manager, he had tokok ahead to ensure that all the production process would be prepared to cope with the requirements of the increasingly demanding customers This year had been difficult. The weather had been exceptionally good, which meant that the harvesting period had been much shorter than malputtinger sure on the factory, which only had a limited daily processing capacity. The factory was designed to produce a range of from vegetables including care cauliflower beans, peas, petit pois, broccoli, and sprouts. It belonged to a large specialist food group, and had an enviable reputation for its high quality standarch Despite John's many years of production management experience, the pea pro Cewing operation had always been his peatest headache during the summer season The previous year had turned out to be an exceptionally long harvesting period of 65 days, which was relatively easy to cope with. However, this year season because of the fine weather, had shrunk to a more normal 1 days, which had mantan immense pressure in getting about the same tonage of peas through the factory in the much shorter period. Tean always caused the worst problems they wete by far the largest crop handled by the factory, and had to be processed in a very short time after being picked John had discussed many times with the Crop Planning Manager, Dave Monson. the possibility of extending the pea growing ason to lessen the pressure on the factory but it was difficult to make any further changes. As Elave explained Well, untortunately you can't plan the weather! Certainly, we do influence when the De should be ready for vining packing by using the best powible planning to ensure that the harvest & spread out over as long a time as possible. You know as well as ido. that the distribution of harvest times can be manipulated for emple, by wing wlected south and north facing fields, different varieties of seed, and planting at different altitudes above sea level. We have continuously worked to make this planning better 269 and to have better cooperation with the grower. We have managed to get them to agree on a target growing plan period of 44 days instead of 36. which is the normal con tract period for growers supplying other factories. But there is a limit in how much we can extend the season-the peas will simply not grow over a longer period, and I believe we have reached the limit. The yield are alio different, depending on the harvesting period. For the first and last quarter of the period the yield is only around 35 tonnes per hectare, whereas in the middle the yield is as much as six tonnes per hectare. The grow ers are naturally more interested in having their main harvest in the middle,tor obvious economice It was only two weeks after the last of this year's harvest had gone through the factory, and the group's operations director had scheduled the following Wednesday to meet with John and the management team. They would go through this year's output figures compared to targets. Each year's targets were set on how many tonnes of frozen peas they would have to produce to satisfy anticipated customer demand The company Although the frozen vegetable business had achieved only slow organic growth. It had continued to invest in improved processing facilities, and to develop better product quality through agricultural technology and practices as well as wine ca the UK is about 200 000 tonnes per annum and the growing area is around 10000 hectares. The human consumption markets there are some sorts of peas used for animal feeds are quite static, but remain important for vining pea growers who have Invested in speciale pent for any in the The typical annual pattern of demand in the UK for froen peas is just the oppo site of that of supply Peas from groen all come in during the summer month with the harvesting lasting between 40 and 60 days, and with the main peak in July. In contrast, sales are at a minimum in the summer, because of the good avail- ability of fresh vegetables, but peak during the winter from Octobetto May, as shown in Figure 28.1. The company's sales target throughput of frozen peas for this year had been is 11 tonnes, measured in the frozen state. Actual output had been slightly higher at 15 396 tonnes as thwn in Table 28.1, much to the station of the management team 770 Figure 28.1 Market for peas in the UK (previous your) Total market demand TE 16 Date Tonnes 189 170 404 Table 2.1 Current year pea output in trozen tonnes Tonnes Date Tonnes 235 29 1377 25 300 157 411 177 241 16 463 22 320 17 524 349 167 492 454 192 452 2012 358 500 210 337 777 2277 236 237 335 461 2T 179 376 257 110 205 379 363 29 30/7 31 28 90 488 514 435 120 102 13 22 1018 TOTAL Retail customers Most of the total market is held by the bigger retailers, including Asda Sateway Kwikave, keland, Somer. Tesco, and Sainsbury. For a producer to be approved by a large retailer, it is critical to offer the right price and the right quality. John's factory focused mainly on the needs of the very demanding UK retailers Sales can be either in bulk form which are subsequently prepared for retail sale by contract packers, or in handed or own-tatel retail packs within cardboard cases, according to requirements. Exports are only in this packed form and only account for a small proportion of sales. Prices depend on which quality the customers ask for, as the peas are graded in qualities ranging from A to where is the top Figure 28,1 Market for peas in the UK (previous year) 16 Tones 370 307 30 Table 28.1 Current year pea output in frasen tonnes Date Tonnes Date Tonnes 286 467 296 3076 134 197 411 21 30 349 492 40 57 2017 358 677 500 21 337 777 476 336 87 335 977 241 179 107 376 21 117 514 351 224 120 102 100 TOTAL Retail customers Most of the total market is held by the bigger retailers, including Anda. Safeway, KwikSave, Keland, Somerfield, Tesco, and Sainsbury. For a producer to be approved by a large retailer, it is critical to offer the right price and the night quality John's factory focused mainly on the needs of these very demanding UK talen Sales can be either in bulk form (which are sequently prepared for retail sale by contract packers, or in branded crown-label retail packs within cardboard cases, according to requirements. Exports are only in this packed form and only account for a small proportion of sales. Prices depend on which quality the customers ask fot, as the peas are graded in qualities tanging from A to D, where is the top prade. The goal is to make as many AA grade peus as possible. The factory had built up an enviable reputation with the retailers for the quality of the product and se vices provided Despite this everyone was continually seeking ways of further increasing quality For instance, it was known that the recently installed steam blanchet should improve final pea quality. A blancher is basically the equipment where the peas get a rapid pre-cook, either in water or in steam, to stop enzymes action which breaks down natural sugars in the peas. This would give tangible benefits in terms of te ture and taste, which could then be marketed at premium prices. By improving the orerall quality of output, the resulting improved profitability would make it poss ible to invest in order to further improve the equipment, thereby achieving even higher levels of quality in the future