Question: Read the article Evaluating the Risks and Challenges of Sole and Single Sourcing and answer the questions below. 1. What is single sourcing? 2. What

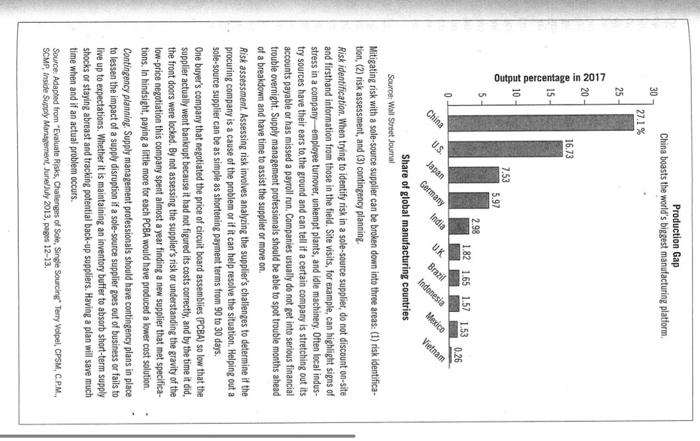

Read the article "Evaluating the Risks and Challenges of Sole and Single Sourcing" and answer the questions below. 1. What is "single sourcing? 2. What are three motivating factors for single sourcing? 3. Examples of single sourcing? 4. How can you mitigate the risk of singlesourcing? 5. What is sole sourcing? 6. Do companies favor sole sourcing? Explain why or why not. 7. Identify three (3) conditions a company would use a sole source. 8. What are the three (3) areas where a company can mitigate their risk if they are using sole sourcing? Evaluating the Risks and Challenges of Sole and Single Sourcing Single sourcing occurs when a supply management organization purposely chooses one of many possible suppliers. The ISM Glossary of Key Supply Management Jermis states, single sourcing is "the practice of deliberately concentrating purchases of a particular item with cone source in preference over others in a competitive marketplace." Often, a single-sourcing strategy is motivated by cost. Some examples include office supplies, travel planning, a p-card provider, of a bank. Generally, the products and services are fairly generic, and the choices are often predicated on cost and contract terms. In some cases, the single-sourcing decision is based on a preferred relationship of product, such as a Mac over a PC. Whatever the reasen, it the source disappeared, you could choose another supplier relatively quickly. The risk of a supply disruption is fairly small and the potential damage caused is comparatively minor with single-source suppliers. The risk to a company's bottom line also is relatively minor, Mitigating the Risk of Single-Sourcing can be performed by having a second source play a minor role in your supply chain, which can help ease some of the pain if the single-source supplier goes out of business or if quality issues occut: If your organization has a single source for office supplies, consider using another office supply company consistently for one or two commodities, such as paper or boxes. In a manufacturing company, for example, use a second foundry to cast a specific line of valves or brass castings only. By having a backup supplier waiting in the wings, a transition, if needed, will be much smoother at a company you have previously done business with. In other words, risk mitigation is important when single sourcing. Sole Sourcing is defined by the ISM Glossary of Key Supply Management Terms as "the use of one source when that source is the only available supplier possessing the ability to fulfill the firm's procurement needs." Although organizations try to avoid sole-source situations, some are unavoidable. There are several cases when an organization would use a sole source and they include conditions when: 1. A supplier holds the patent on a part or product the procuring company needs. 2. Only one company is licensed to produce a certain item or holds the intellectual property rights to a needed product or service. 3. A custom part is needed by a company and the tooliag costs for the custom part are very expensive. In this case, if the buyer chooses to purchase the tooling then the sole source could become a single source if other suppliers can make the item. 4. Only one company has the most efficient process to produce a product, making it significantly less expensive than any alternative. 5. Your company holds patent rights and intellectual property that need to be carefully guarded. In this case, the supply management organization chooses one supplier to produce the item to avoid sharing seasitive information with a variety of suppliers. In this type of scenario, supply managernent professionals must first lock down security provisions in a detailed contract. As illustrated earlier, in cases 3,4 , and 5 other suppliers are available making the "sole" supplier designation less firm. Sottware is a classic example of the earlier conditions. Though it is possible to make a change if your software provider goes out of business, it can be expensive and time-consuming. Unfortunately, sole sourcing opens your coinpany to a greater risk of supply disfuption. Share of global manufacturing countries Source: Wall Street Journal Mitigating risk with a sole-source supplier can be broken down into three areas: (1) risk identification, (2) risk assessment, and (3) contingency planning. Risk identification. When trying to identify risk in a sole-scurce supplier, do not discount on-site and firsthand information from those in the field. Site visits, for example, can highlight signs of stress in a company-employee turnover, unkempt plants, and idle machinery. Often local industry sources have their ears to, the ground and can tell if a certain company is stretching out its accounts payable or has missed a payroll run. Companies usually do not get into serious financial trouble overnight. Supply management professionals should be able to spot trouble months ahead of a breakdown and have time to assist the supplier of move on. Risk assessment. Assessing risk imvolves analyzing the supplier's challenges to determine it the procuring company is a cause of the problem or if it can help resolve the situation. Helping out a sole-source supplier can be as simple as shortening payment terms from 90 to 30 dajs. One buyer's company that negotiated the price of circuit board assemblies (PCBA) so low that the sapplier actually went bankrupt because it had not figured its costs correctly, and by the time it did, the front doors were locked. By not assessing the supplier's risk of understanding the gravity of the low-price negotiation this company spent almost a year finding a new supplier that met specifications. In hindsight, paying a little more for each PCBA would have produced a lower cost solution. Contingency planning. Supply management professionals should have contingency plans in place to lessen the impact of a supply disruption if a sole-source supplier goes out of business or fails to live up to expectations. Whether it is maintaining an inventory buffer to absorb short-term supply shocks or staying abreast and tracking potential back-up suppliers. Haviag a plan will save much time when and if an actual problem occurs. Source. Adaphod from "Evaluate Risks, Chalenges of Solie, Single Sourcing" Terry Volpel, CPSM, C.PM., SCMP, Inside Supply Management, Junelluly 2013, pages 12-13