Question: Read the text above and answer the question below: Write about the impact of Information Sharing on a Supply chain as shown in our example

Read the text above and answer the question below: Write about the impact of Information Sharing on a Supply chain as shown in our example in the fotos above

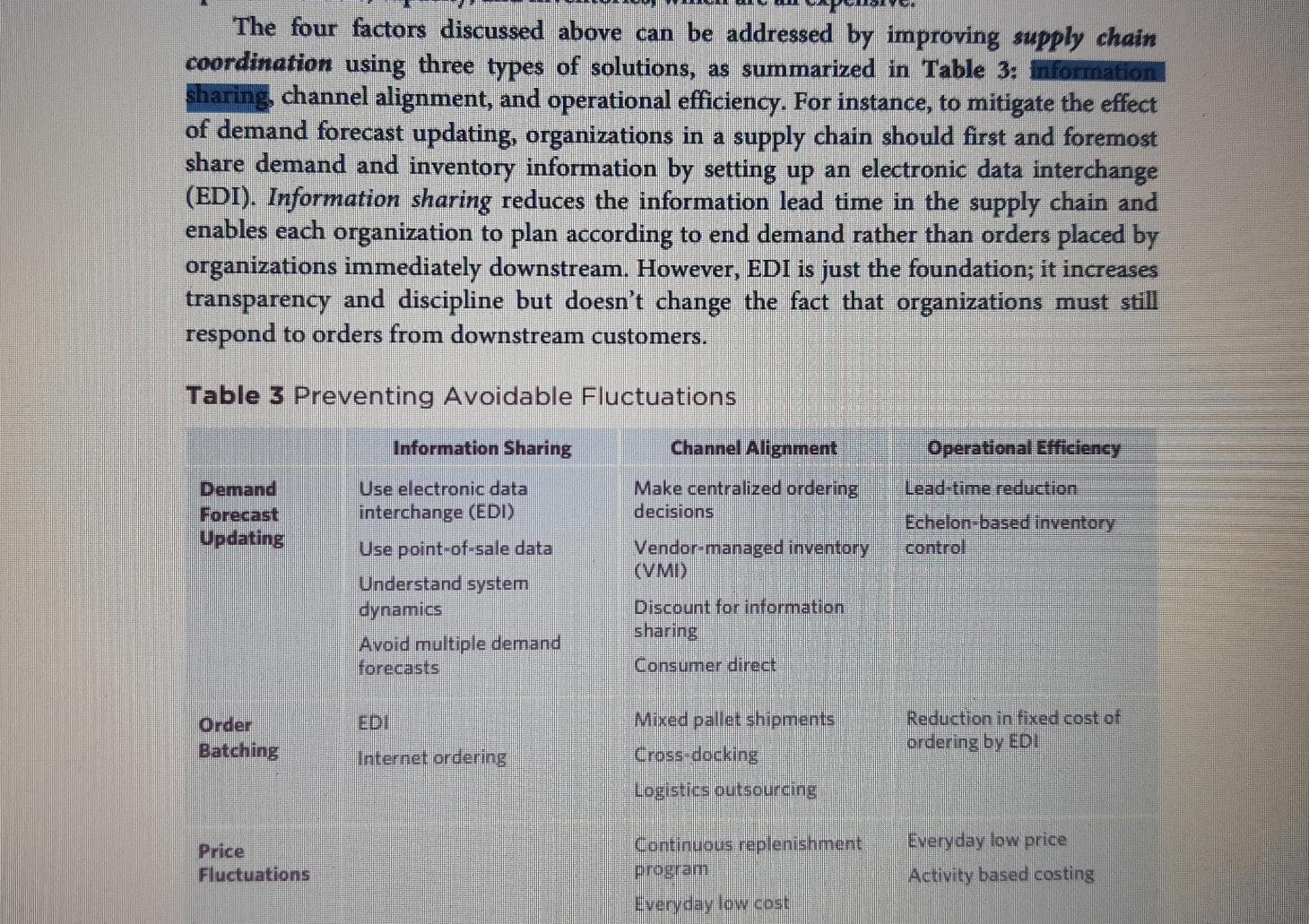

The four factors discussed above can be addressed by improving supply chain coordination using three types of solutions, as summarized in Table 3: Information sharing, channel alignment, and operational efficiency. For instance, to mitigate the effect of demand forecast updating, organizations in a supply chain should first and foremost share demand and inventory information by setting up an electronic data interchange (EDI). Information sharing reduces the information lead time in the supply chain and enables each organization to plan according to end demand rather than orders placed by organizations immediately downstream. However, EDI is just the foundation; it increases transparency and discipline but doesn't change the fact that organizations must still respond to orders from downstream customers. Table 3 Preventing Avoidable Fluctuations Information Sharing Channel Alignment Operational Efficiency Lead-time reduction Demand Forecast Updating Make centralized ordering decisions Echelon-based inventory control Use electronic data interchange (EDI) Use point-of-sale data Understand system dynamics Avoid multiple demand forecasts Vendor-managed inventory (VMI) Discount for information sharing Consumer direct EDI Mixed pallet shipments Order Batching Reduction in fixed cost of ordering by EDI Internet ordering Cross-docking Logistics outsourcing Price Fluctuations Continuous replenishment program Every day low cost Everyday low price Activity based costing Rationing and Shortage Gaming Sharing sales, inventory. and capacity data Allocation based on past sales In recent years, radio-frequency identification (RFID) has been increasingly used to improve information richness, increase transparency, and reduce data errors in supply chains. RFID tags attached to pallets (the unit of movement of goods in factories and warehouses), case packs, and individual items can be scanned efficiently and cost- effectively at various stages of the supply chain so that their exact location is known. For example, a retailer would know how much inventory of different items is in shipment, a manufacturer would know how much of its inventory is in a retailer's backroom and how much is on the selling floor, and so on. Manufacturers and retailers can then use such information to anticipate future orders and plan their respective inventories to reduce the bullwhip effect. Supply chain organizations can realize considerable additional benefit by using shared information to coordinate their forecasting, production, and stocking decisions. Frameworks for such channel alignment include vendor managed inventory (VMI), 2.5 Improving Responsiveness As we have noted, products with short life cycles are increasingly common. An article of fashion clothing, for example, typically has a selling season of two or three months but a production lead time of nine to twelve months. Production orders must be placed well before the start of the season to fulfill commitments through the complex supply chain. Once the season starts, the firm has no recourse. Two attributes of such products make them costly to manage: uncertain demand forecasts and long lead times. It is difficult to forecast demand, and thus plan production, for short-life-cycle products because there is typically no historical demand or sales data available. In these instances, the time series forecasting models that are embedded in ERP systems are not effective. Instead, managers must rely on their judgment and experience. Such "Judgmental forecasts tend to be noisy, and so the firm loses revenue and incurs the considerable cost of excess inventory. Long lead times exacerbate the problems of noisy demand forecasts by making it harder for managers to react to changes in demand. Managers of such products must focus on improving the speed of the supply chain-that is, making it more responsive. Managers can undertake many initiatives to develop responsive supply chains. They can choose suppliers located close to the demand base that can provide shorter lead time and integrate their processes better with the buyer firm. They can also coordinate information sharing with suppliers, reserve production and distribution capacity in advance, and pre-position raw materials so that production can be triggered at short notice. Zara, which we mentioned earlier in discussing market-responsive supply chains, provides a good example of such a supply chain. The company designs its products in- house, maintains raw material inventories, produces in its own factories, ships all finished merchandise to a central distribution facility, and then allocates merchandise to stores all over the world several times a week. By tightly coordinating all these activities, Zara is able to quickly respond to changes in demand and deliver "fast fashion." Its supply chain is so responsive that the total flow time of a product from design to store can be as little as 10 daysStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts