Question: Reading: Learning Units 2 Outcome: Evaluate and screen process flowsheet alternatives Question 1 A conceptual design for a cumene production process (250 toniday of cumene)

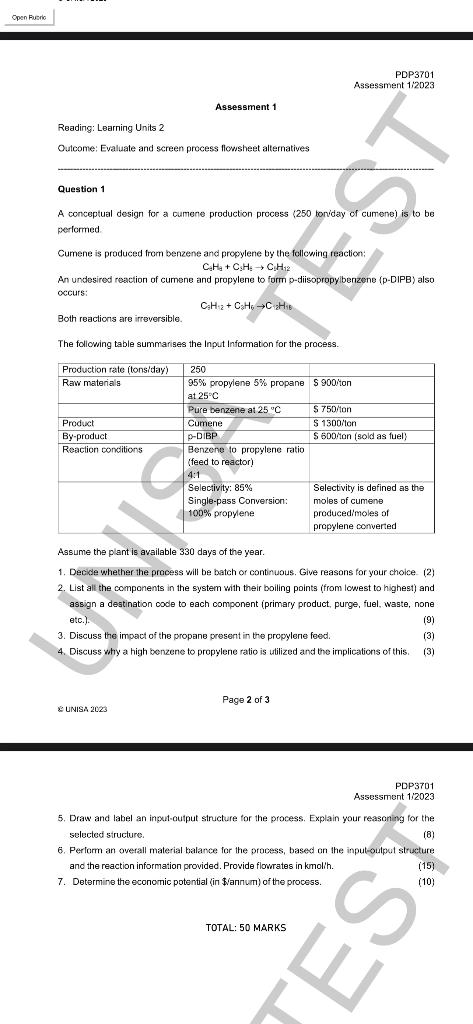

Reading: Learning Units 2 Outcome: Evaluate and screen process flowsheet alternatives Question 1 A conceptual design for a cumene production process (250 toniday of cumene) is to be performed Cumene is produced from benzene and propylene by the following reaction; C4H4+C9H2C5H12 An undesired reaction of cumene and propylene to form p-diisopropy benzene (p-DIPB) also occurs: C3H12+C3H6C23H16 Both reactions are irreversible. The following table summarises the input Information for the process. Assume the plant is available 330 days of the year. 1. Decide whether the process will be batch or continuous. Give reasons for your choice. (2) 2. List all the components in the system with their boiling points (from lowest to highest) and assign a destination code to each component iprimary product, purge, fuel, waste, none etc.). (9) 3. Discuss the impact of the propane present in the propylene feed. (3) 4. Discuss why a high benzene to propylene ratio is utilized and the implications of this. (3) Page 2 of 3 UNISA 2023 PDP3701 Assessment 1/2023 5. Draw and label an input-output structure tor the process. Explain your reasoning for the selected siructure. (8) 6. Perform an overall material balance for the process, based on the input-oulput structure and the reaction information provided. Provide flowrates in kmolih. (15) 7. Determine the economic potential (in \$iannum) of the process

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts