Question: really could use some help solving this problem. thank you You have been asked to balance a flow shop assembly operation to achieve an output

really could use some help solving this problem. thank you

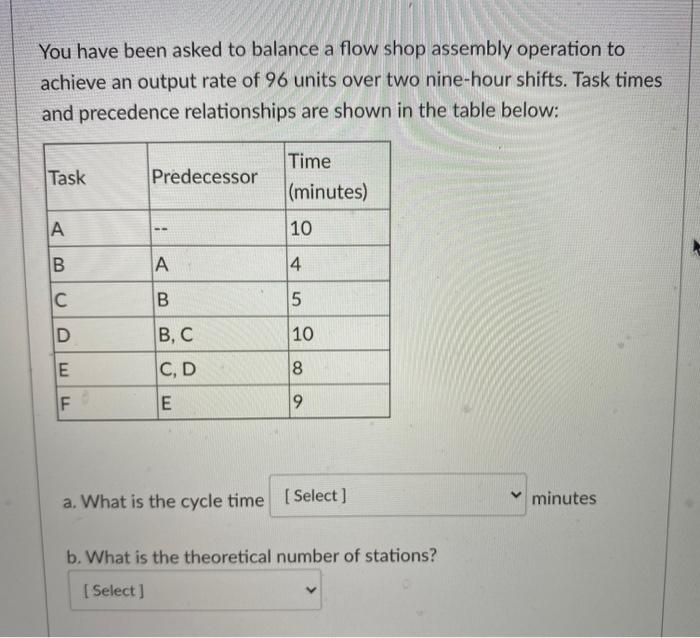

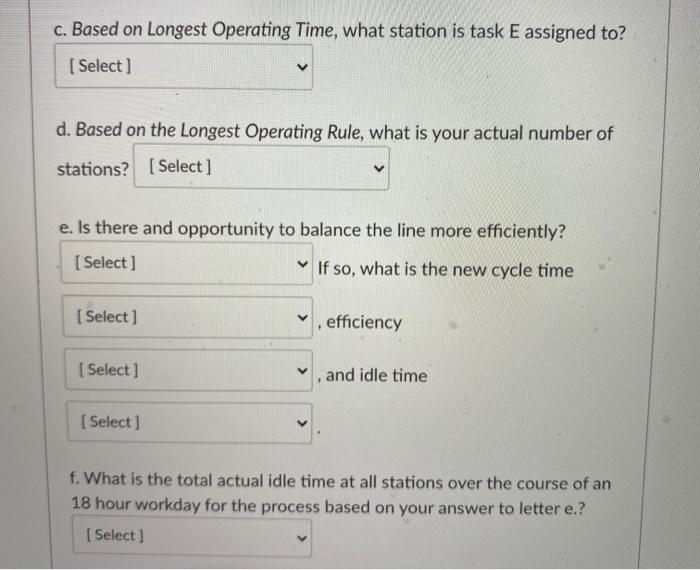

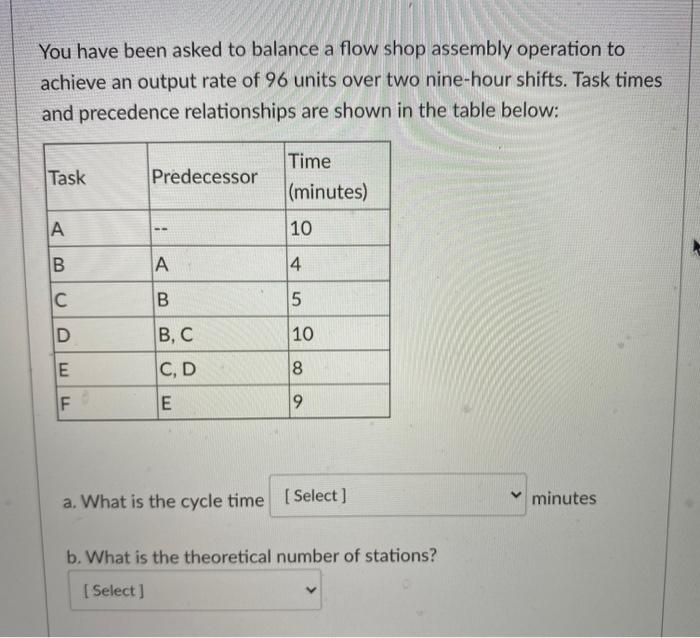

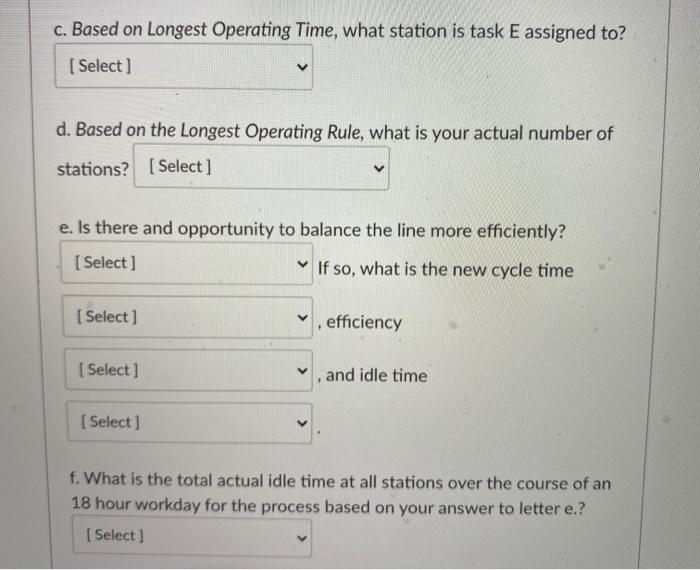

You have been asked to balance a flow shop assembly operation to achieve an output rate of 96 units over two nine-hour shifts. Task times and precedence relationships are shown in the table below: Task Predecessor Time (minutes) A -- 10 B A 4 IC B LO D B, C 10 E C, D 00 F E 19 a. What is the cycle time (Select ] minutes b. What is the theoretical number of stations? [Select ] c. Based on Longest Operating Time, what station is task E assigned to? Select] d. Based on the Longest Operating Rule, what is your actual number of stations? [Select] e. Is there and opportunity to balance the line more efficiently? [ Select] If so, what is the new cycle time [ Select) efficiency [ Select) . and idle time [ Select) f. What is the total actual idle time at all stations over the course of an 18 hour workday for the process based on your answer to letter e.? [Select]

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock