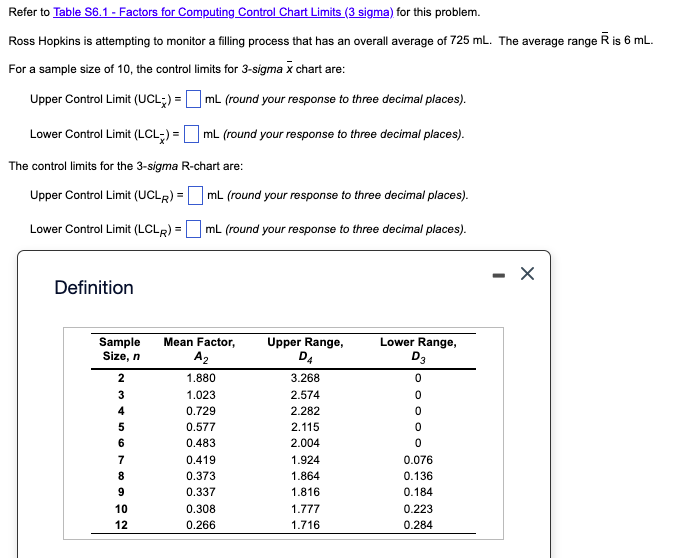

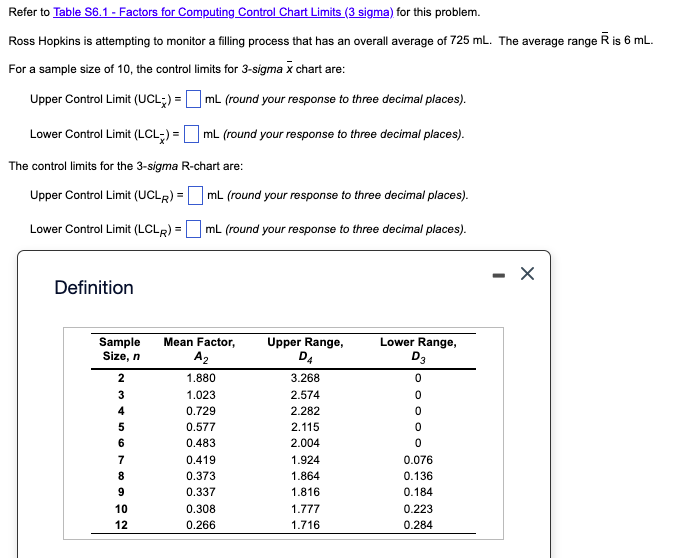

Question: Refer to Table S6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. Ross Hopkins is attempting to monitor a filling process

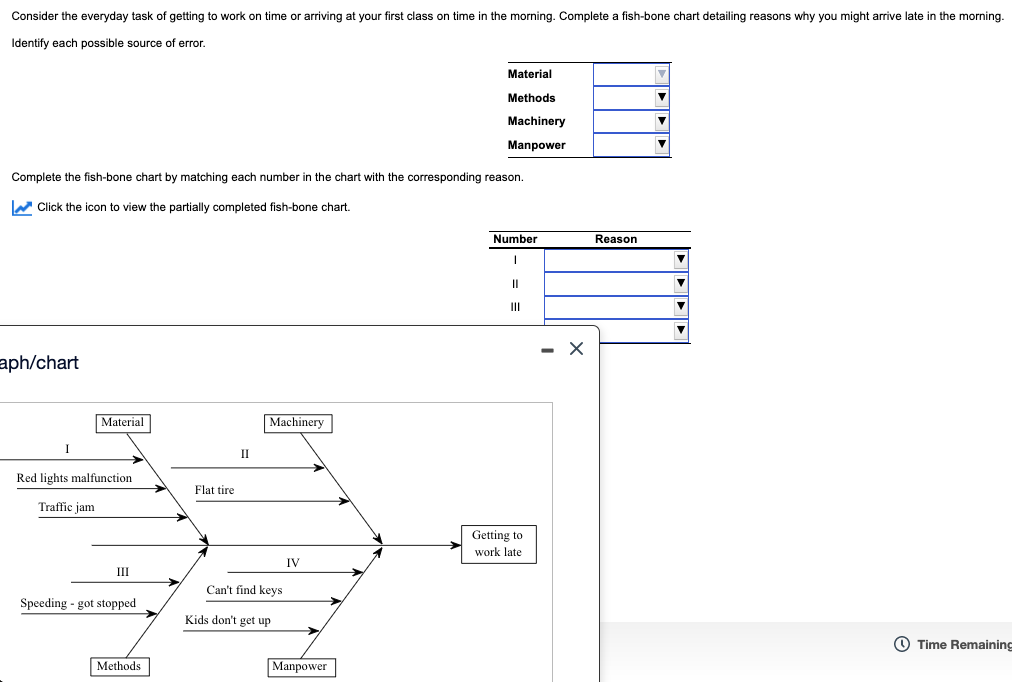

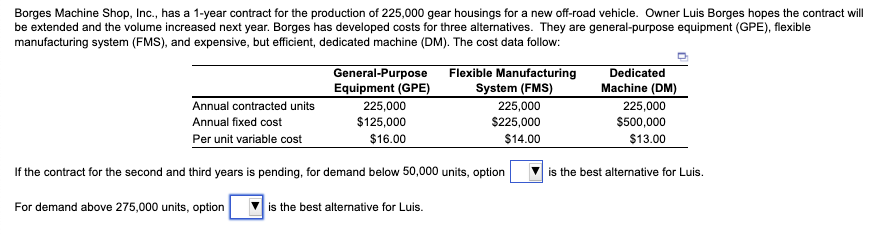

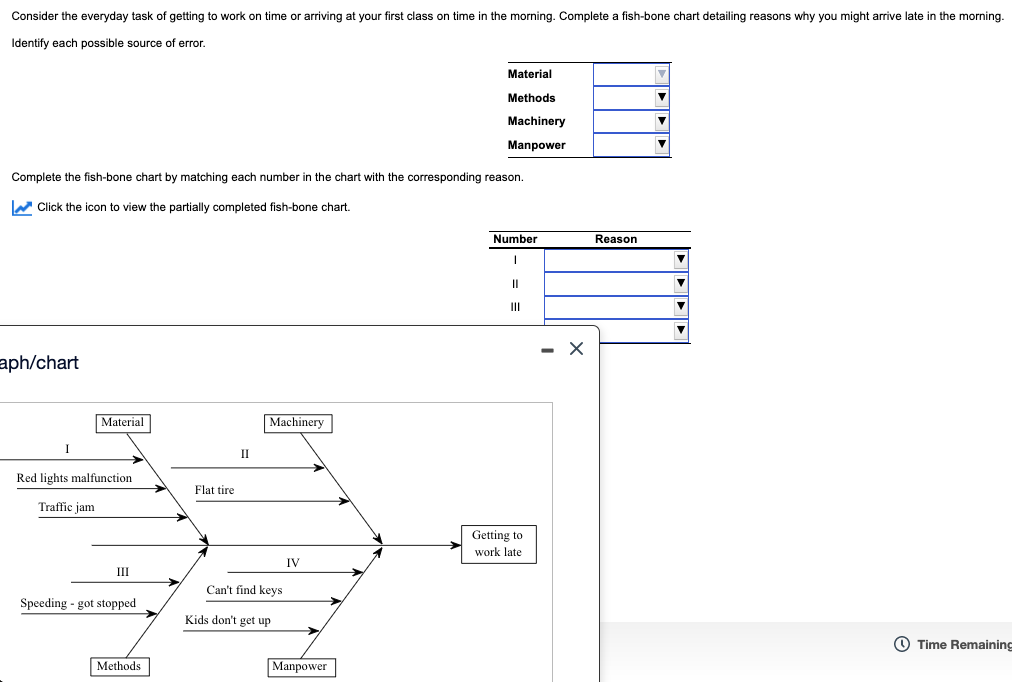

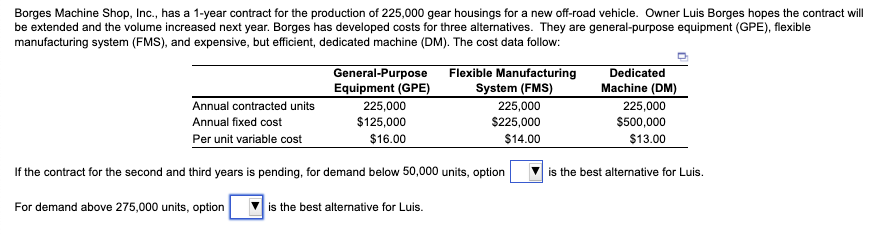

Refer to Table S6.1 - Factors for Computing Control Chart Limits (3 sigma) for this problem. Ross Hopkins is attempting to monitor a filling process that has an overall average of 725 ml. The average range R is 6 ml. R For a sample size of 10, the control limits for 3-sigma x chart are: Upper Control Limit (UCL;) = ml (round your response to three decimal places). Lower Control Limit (LCL) = ml (round your response to three decimal places). The control limits for the 3-sigma R-chart are: Upper Control Limit (UCLR) = ml (round your response to three decimal places). Lower Control Limit (LCLR) = mL (round your response to three decimal places). - - X Definition Lower Range, D 0 0 0 O O Sample Size, n 2 3 4 5 6 7 8 9 10 12 Mean Factor, Az 1.880 1.023 0.729 0.577 0.483 0.419 0.373 0.337 0.308 0.266 Upper Range, D4 3.268 2.574 2.282 2.115 2.004 1.924 1.864 1.816 1.777 1.716 0.076 0.136 0.184 0.223 0.284 Consider the everyday task of getting to work on time or arriving at your first class on time in the morning. Complete a fish-bone chart detailing reasons why you might arrive late in the morning. Identify each possible source of error. Material Methods Machinery Manpower Complete the fish-bone chart by matching each number in the chart with the corresponding reason. Click the icon to view the partially completed fish-bone chart. Number Reason 1 11 III aph/chart Material Machinery II Red lights malfunction Flat tire Traffic jam Getting to work late IV III Can't find keys Speeding - got stopped Kids don't get up Time Remaining Methods Manpower Borges Machine Shop, Inc., has a 1-year contract for the production of 225,000 gear housings for a new off-road vehicle. Owner Luis Borges hopes the contract will be extended and the volume increased next year. Borges has developed costs for three alternatives. They are general-purpose equipment (GPE), flexible manufacturing system (FMS), and expensive, but efficient, dedicated machine (DM). The cost data follow: Annual contracted units Annual fixed cost Per unit variable cost General-Purpose Equipment (GPE) 225,000 $125,000 $16.00 Flexible Manufacturing System (FMS) 225,000 $225,000 $14.00 Dedicated Machine (DM) 225,000 $500,000 $13.00 If the contract for the second and third years is pending, for demand below 50,000 units, option is the best alternative for Luis. For demand above 275,000 units, option is the best alternative for Luis