Question: Request you answer question number 3 in excel and provide the applicable excel data. Senco Electronics Company (Senco) is a U.S.-based manufacturer of personal comput-

Request you answer question number 3 in excel and provide the applicable excel data.

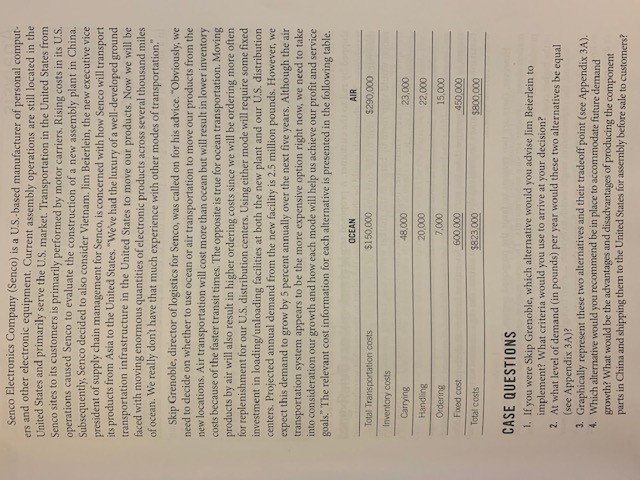

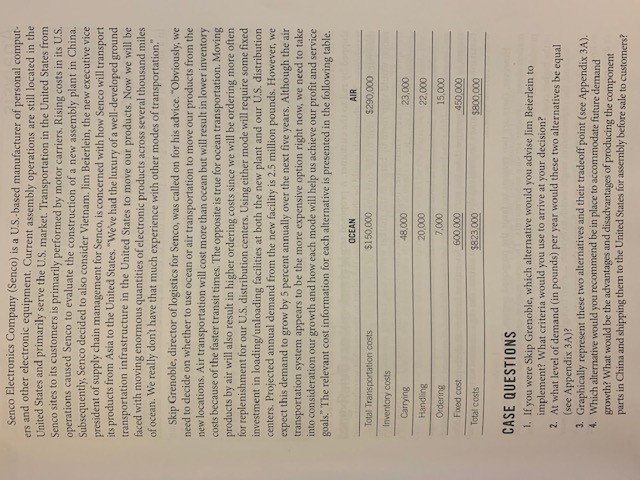

Senco Electronics Company (Senco) is a U.S.-based manufacturer of personal comput- ers and other electronic equipment. Current assembly operations are still located in the United States and primarily serve the U.S. market. Transportation in the United States from Senco sites to its customers is primarily performed by motor carriers. Rising costs in its U.S. operations caused Senco to evaluate the construction of a new assembly plant in China. Subsequently, Senco decided to also consider Vietnam. Jim Beierlein, the new executive vice president of supply chain management for Senco, is concerned with how Senco will transport its products from Asia to the United States. "We've had the luxury of a well-developed ground transportation infrastructure in the United States to move our products. Now we will be faced with moving enormous quantities of electronic products across several thousand miles of ocean. We really don't have that much experience with other modes of transportation." Skip Grenoble, director of logistics for Senco, was called on for his advice. "Obviously, we need to decide on whether to use ocean or air transportation to move our products from the new locations. Air transportation will cost more than ocean but will result in lower inventory costs because of the faster transit times. The opposite is true for ocean transportation. Moving products by air will also result in higher ordering costs since we will be ordering more often for replenishment for our U.S. distribution centers. Using either mode will require some fixed investment in loading/unloading facilities at both the new plant and our U.S. distribution centers. Projected annual demand from the new facility is 2.5 million pounds. However, we expect this demand to grow by 5 percent annually over the next five years. Although the air transportation system appears to be the more expensive option right now, we need to take into consideration our growth and how each mode will help us achieve our profit and service goals." The relevant cost information for each alternative is presented in the following table. OCEAN AIR $290,000 $150,000 Total Transportation costs Inventory costs Carrying Handling Ordering Fixed cost 48,000 20.000 7.000 600.000 $823,000 23,000 22.000 15,000 450,000 $800.000 Total costs CASE QUESTIONS 1. If you were Skip Grenoble, which alternative would you advise Jim Beierlein to implement? What criteria would you use to arrive at your decision? 2. At what level of demand (in pounds) per year would these two alternatives be equal (see Appendix 3A)? 3. Graphically represent these two alternatives and their tradeoff point (see Appendix 3A). 4. Which alternative would you recommend be in place to accommodate future demand growth? What would be the advantages and disadvantages of producing the component parts in China and shipping them to the United States for assembly before sale to customers