Question: Requested daily quantity for a product is 375 units (defect free). The production times (given as normal time) of the three operations respectively are as

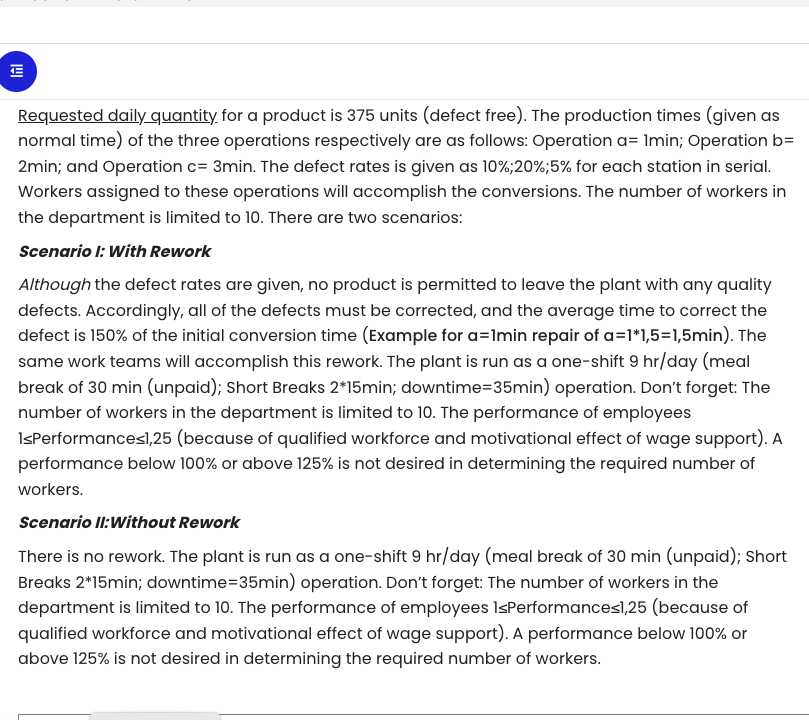

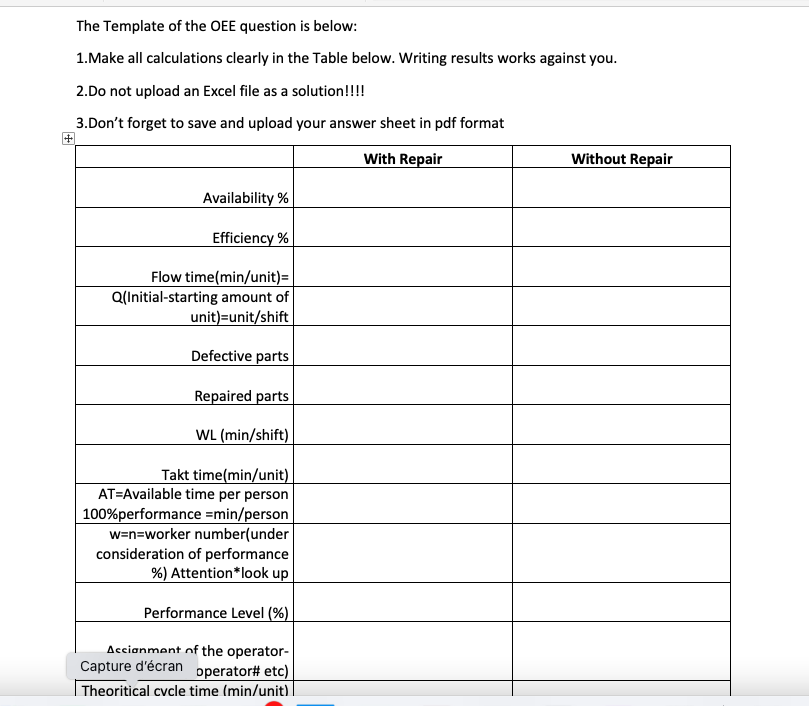

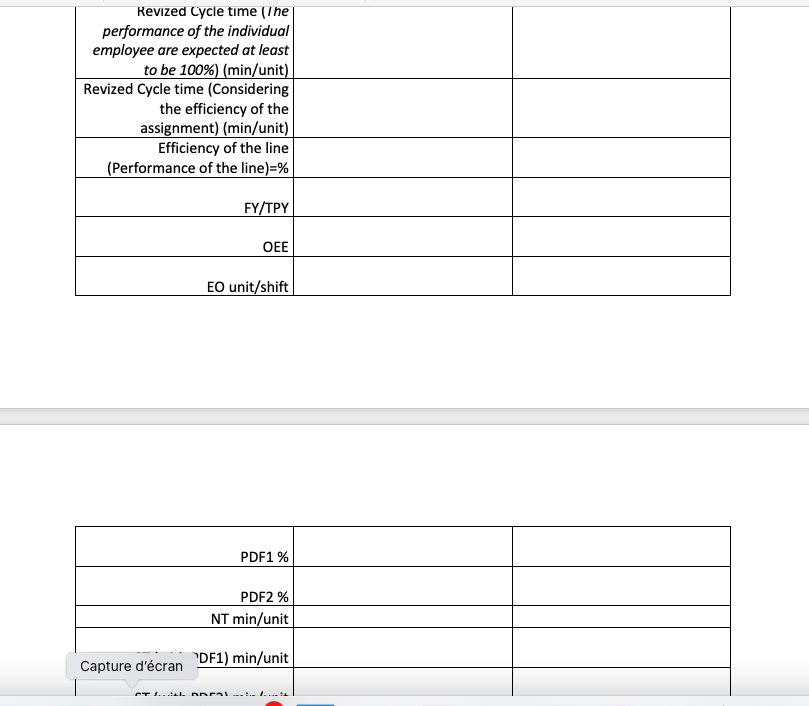

Requested daily quantity for a product is 375 units (defect free). The production times (given as normal time) of the three operations respectively are as follows: Operation a=1min; Operation b= 2min; and Operation c=3min. The defect rates is given as 10%;20%;5% for each station in serial. Workers assigned to these operations will accomplish the conversions. The number of workers in the department is limited to 10 . There are two scenarios: Scenario I: With Rework Although the defect rates are given, no product is permitted to leave the plant with any quality defects. Accordingly, all of the defects must be corrected, and the average time to correct the defect is 150% of the initial conversion time (Example for a=1min repair of a=11,5=1,5min ). The same work teams will accomplish this rework. The plant is run as a one-shift 9hr/day (meal break of 30min (unpaid); Short Breaks 2*15min; downtime=35min) operation. Don't forget: The number of workers in the department is limited to 10. The performance of employees 1sPerformances1,25 (because of qualified workforce and motivational effect of wage support). A performance below 100% or above 125% is not desired in determining the required number of workers. Scenario Il:Without Rework There is no rework. The plant is run as a one-shift 9hr/ day (meal break of 30min (unpaid); Short Breaks 2*15min; downtime=35min) operation. Don't forget: The number of workers in the department is limited to 10. The performance of employees 1sPerformances1,25 (because of qualified workforce and motivational effect of wage support). A performance below 100% or above 125% is not desired in determining the required number of workers. The Template of the OEE question is below: 1.Make all calculations clearly in the Table below. Writing results works against you. 2.Do not upload an Excel file as a solution!!!! 3.Don't forget to save and upload your answer sheet in pdf format \begin{tabular}{|r|r|r|} RevizedCycletime(Iheperformanceoftheindividualemployeeareexpectedatleasttobe100%)(min/unit) & & \\ \hline RevizedCycletime(Consideringtheefficiencyoftheassignment)(min/unit) & & \\ \hline Efficiencyoftheline(Performanceoftheline)=% & & \\ \hline FY/TPY & & \\ \hline OEE & & \\ \hline EO unit/shift & & \\ \hline \end{tabular} Draw a sketch showing the station-operator assignment (With \& Without Repair) Prove the FY of your new redesigned station assignment (With \& Without Repair) If there is a 10% of Efficiency Improvement (not temporary it's permanent) what will the effect on OEE? (Hint: OEE; w; Assignment etc) Capture d'cran 'Efficiency of the line (=Performance of the line) (by using an incentive system nascu v periumance) what will the effect on OEE? (Hint: OEE; w; Assignment etc)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts