Question: Second, the demand for natural gas was soaring because it was the cleanest and most efficient fuel. There were almost no environmental problems in burning

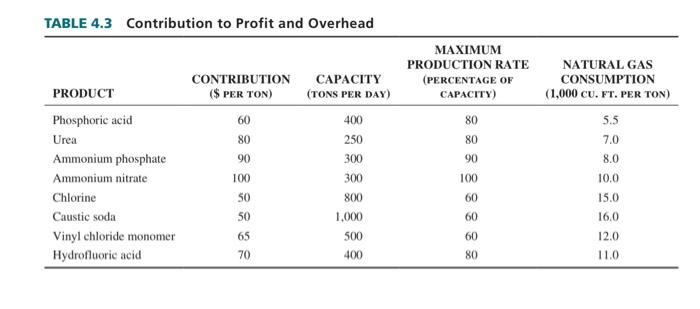

Second, the demand for natural gas was soaring because it was the cleanest and most efficient fuel. There were almost no environmental problems in burning natural gas. Moreover, maintenance problems due to fuel-fouling in fireboxes and boilers were negligible with natural gas systems. Also, burn- ers were much easier to operate with natural gas than with oil or coal. Finally, the supply of natural gas was dwindling. The traditionally depressed price of natural gas had discouraged new exploration for gas wells; hence, shortages appeared imminent. Stock and his staff at Coastal States had been aware of the possibility of shortages of natural gas and had been investigat- ing ways of converting to fuel oil or coal as a substitute for natural gas. Their plans, however, were still in the develop- mental stages. Coastal States required an immediate contin- gency plan to minimize the effect of a natural gas curtailment on its multiplant, operations. The obvious question was, what operations should be curtailed, and to what extent could the adverse effect upon profits be minimized? Coastal States had approval from the FPC and Cajan Pipeline to specify which of its plants would bear the burden of the curtailment if such cutbacks were necessary. McNair, of Cajan Pipeline, replied. "It's your 'pie': we don't care how you divide it if we make it smaller." The Model Six plants of Coastal States Louisiana Division were to share in the pie." They were all located in the massive Baton Rouge- Geismar-Gramercy industrial complex along the Mississippi River between Baton Rouge and New Orleans. Products man- ufactured at those plants that required significant amounts of natural gas were phosphoric acid, urea, ammonium phosphate, ammonium nitrate, chlorine, caustic soda, vinyl chloride monomer, and hydrofluoric acid. Stock called a meeting of members of his technical staff to discuss a contingency plan for allocation of natural gas among the products if a curtailment developed. The objective was to minimize the impact on profits. After detailed discus- sion, the meeting was adjourned. Two weeks later, the meet- ing reconvened. At this session, the data in Table 4.3 were presented. Coastal States' contract with Cajan Pipeline specified a maximum natural gas consumption of 36,000,000 cubic feet per day for all six member plants. With these data, the tech- nical staff proceeded to develop a model that would specify changes in production rates in response to a natural gas curtail- ment. (Curtailments are based on contracted consumption and not current consumption.) Develop the Sensitivity Report for the 20% natural gas curtailment model. Use this report to answer the following questions. Each question is independent of the others. (a) Interpret the shadow prices for the natural gas avail- ability constraint and for the two constraints that limit the maximum phosphoric acid and chlorine that Coastal can produce. (b) Brenda Lamb, Bill Stock's marketing manager, believes that due to increased competition she may have to decrease the unit profit contributions for all products by 3.5% each. What is the impact of this de- crease on the production values? On the total profit? (c) Jose Fernandez, Bill Stock's production manager, thinks that he can increase the maximum production rate for chlorine and vinyl chloride monomer to 80% of capacity. For all other products, he thinks he can increase the maximum production rate to 100% of capacity. What would be the impact of this change on the total profit? TABLE 4.3 Contribution to Profit and Overhead CONTRIBUTION ($ PER TON) MAXIMUM PRODUCTION RATE (PERCENTAGE OF CAPACITY) NATURAL GAS CONSUMPTION (1,000 CU. FT. PER TON) 5.5 7.0 PRODUCT Phosphoric acid Urea Ammonium phosphate Ammonium nitrate Chlorine Caustic soda Vinyl chloride monomer Hydrofluoric acid 60 80 90 100 50 50 CAPACITY (TONS PER DAY) 400 250 300 300 800 1.000 500 400 80 80 90 100 60 8.0 10.0 15.0 16.0 12.0 11.0 60 65 60 70 80