Question: Section A - Case study question (40 marks) Denver Corporation Denver Corporation, a European based company, owns several major divisions, including the Aluminium Can division

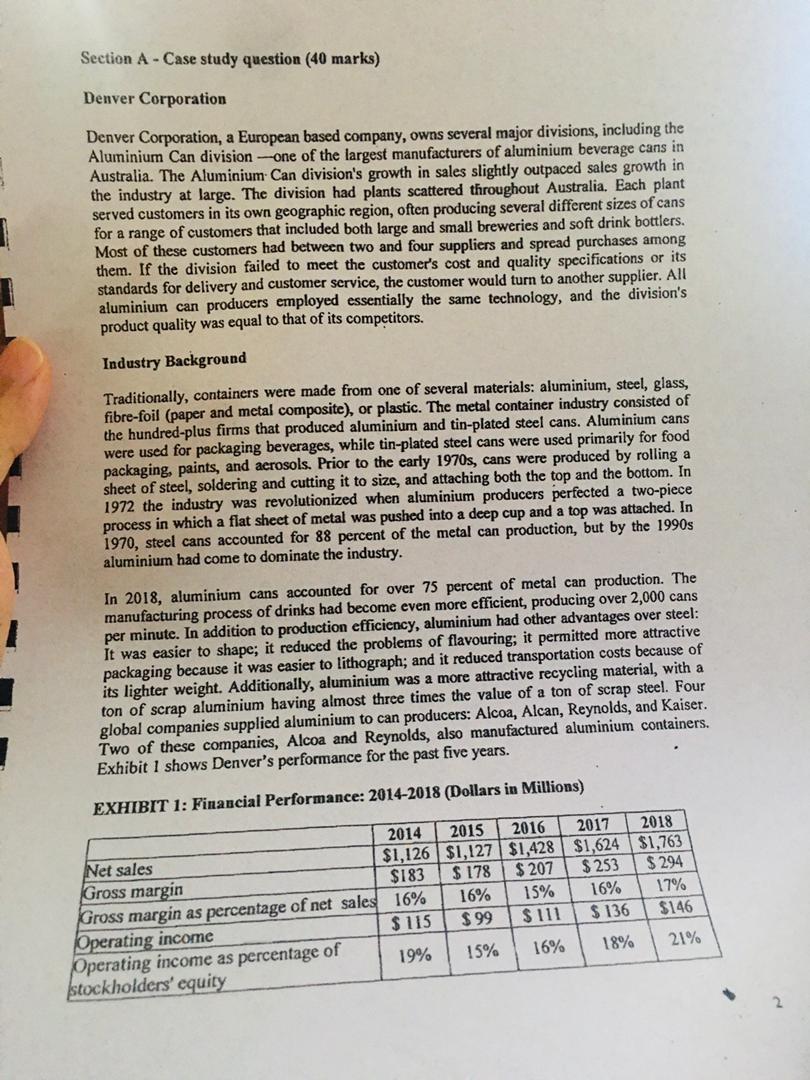

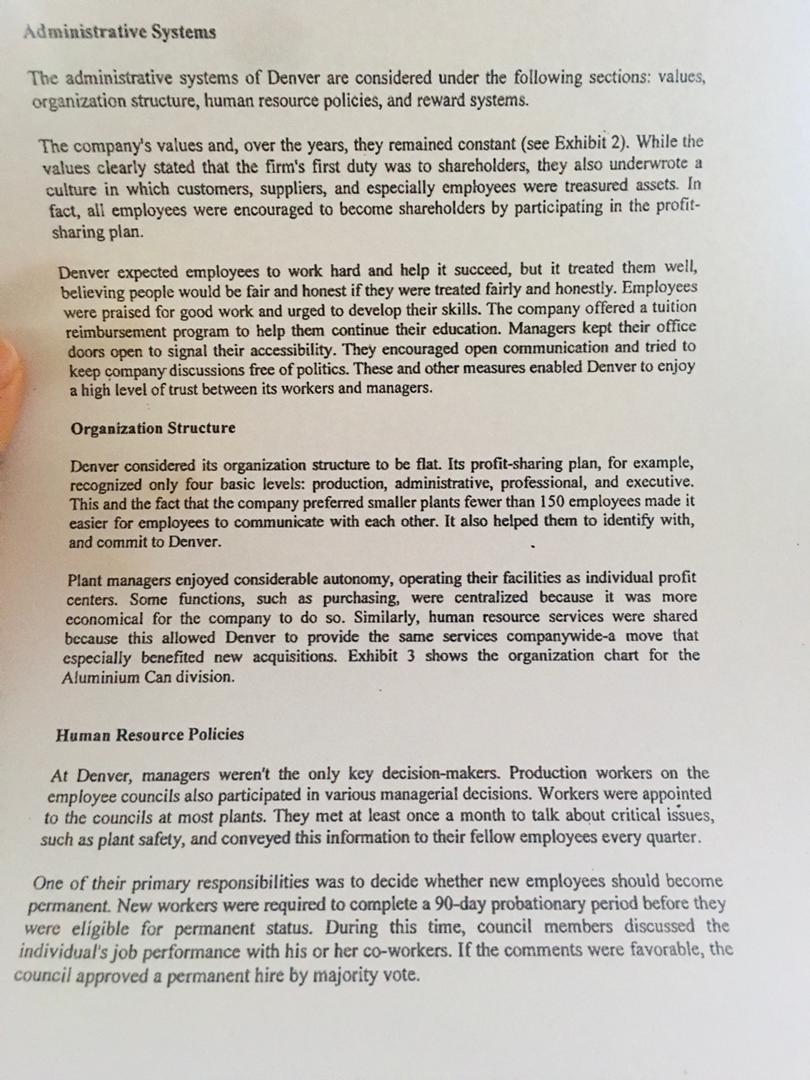

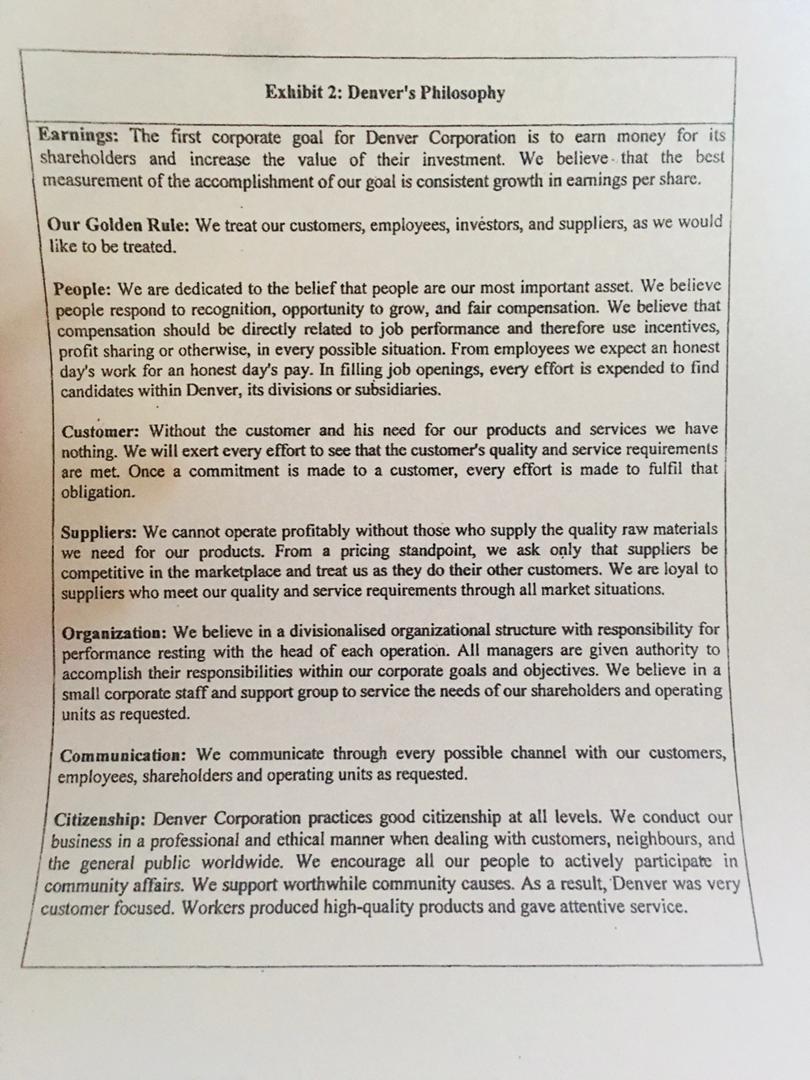

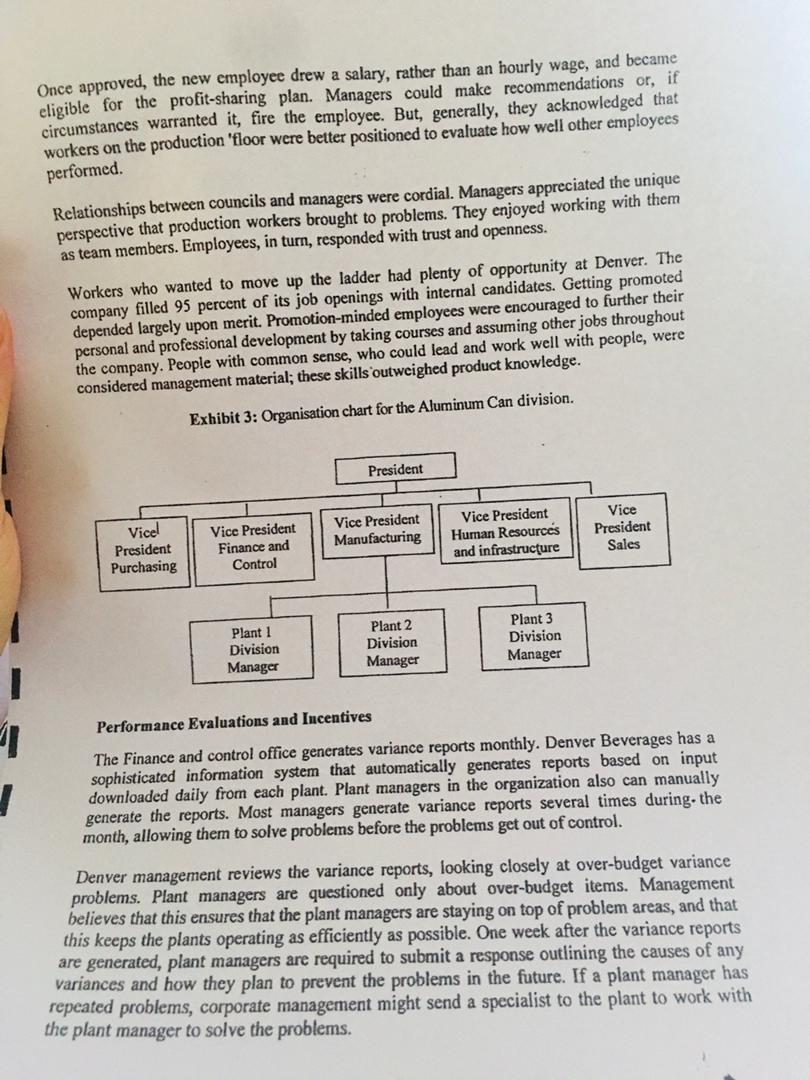

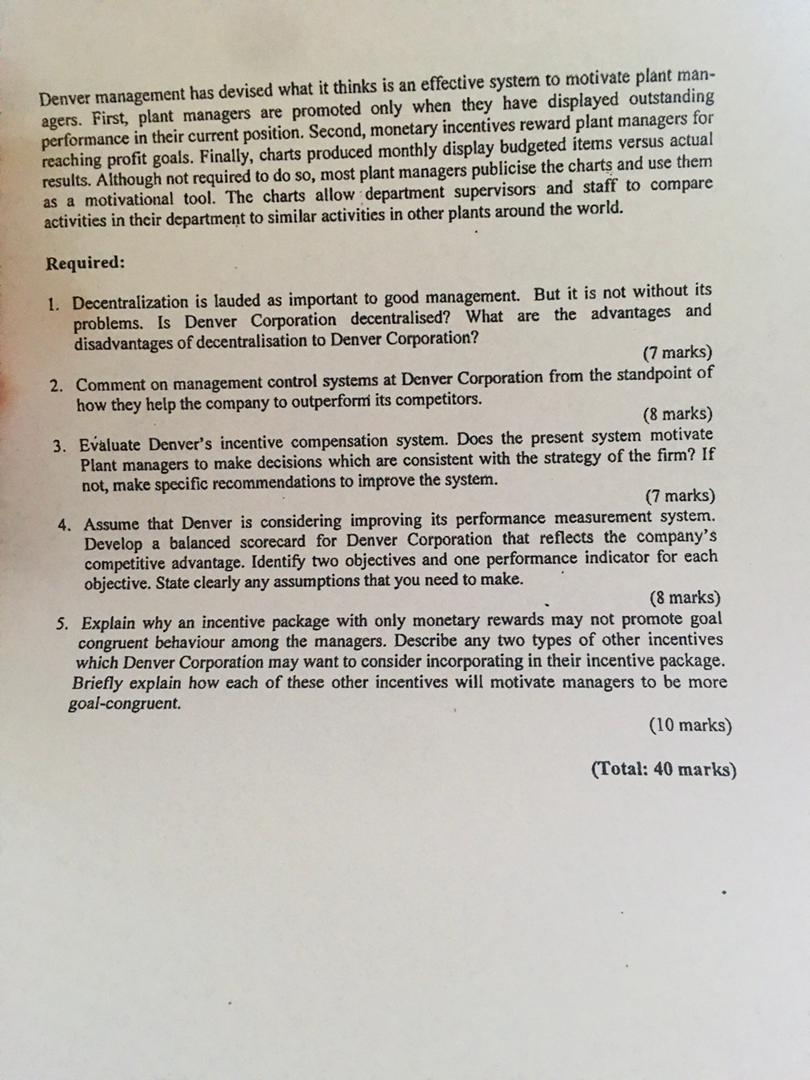

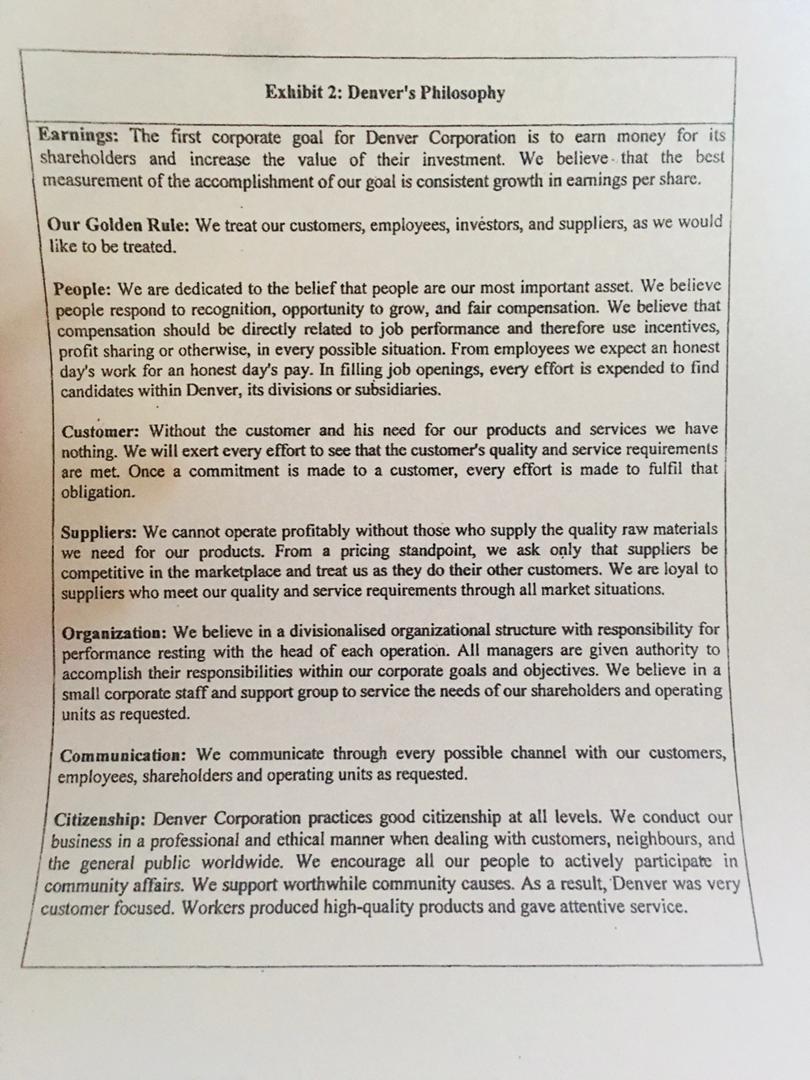

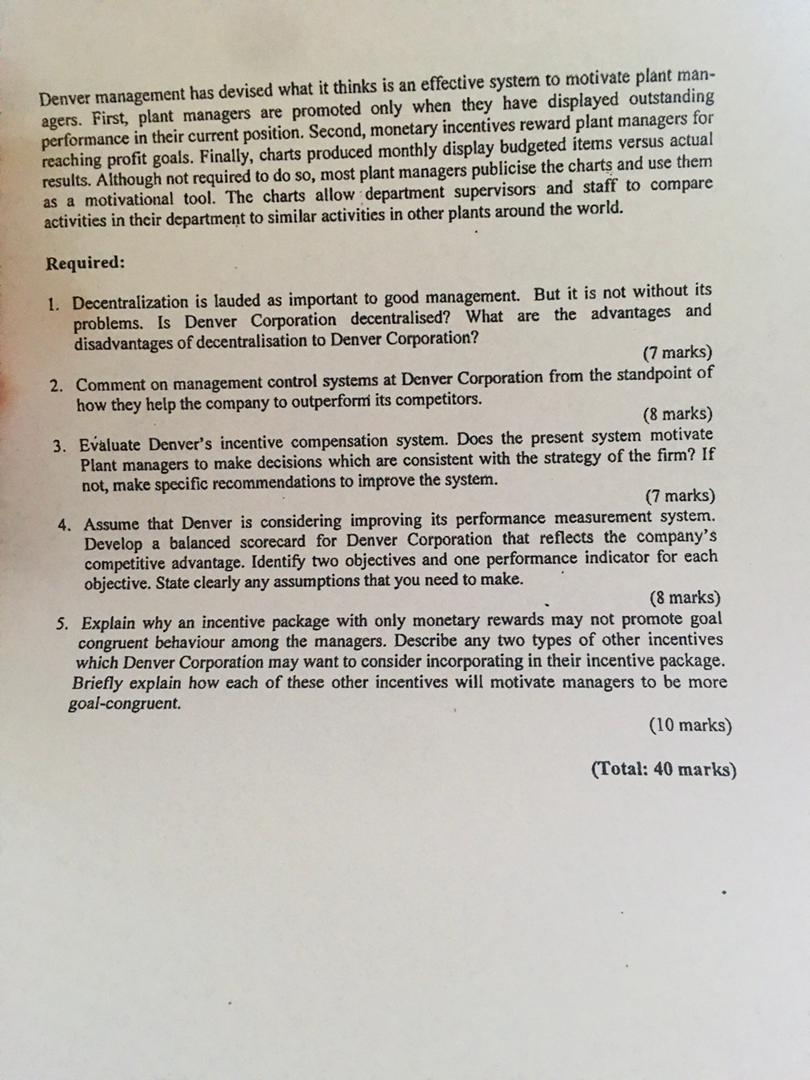

Section A - Case study question (40 marks) Denver Corporation Denver Corporation, a European based company, owns several major divisions, including the Aluminium Can division ---one of the largest manufacturers of aluminium beverage cans in Australia. The Aluminium Can division's growth in sales slightly outpaced sales growth in the industry at large. The division had plants scattered throughout Australia. Each plant served customers in its own geographic region, often producing several different sizes of cans for a range of customers that included both large and small breweries and soft drink bottlers. Most of these customers had between two and four suppliers and spread purchases among them. If the division failed to meet the customer's cost and quality specifications or its standards for delivery and customer service, the customer would turn to another supplier. All aluminium can producers employed essentially the same technology, and the division's product quality was equal to that of its competitors. Industry Background Traditionally, containers were made from one of several materials: aluminium, steel, glass, fibre-foil (paper and metal composite), or plastic. The metal container industry consisted of the hundred-plus firms that produced aluminium and tin-plated steel cans. Aluminium cans were used for packaging beverages, while tin-plated steel cans were used primarily for food packaging, paints, and aerosols. Prior to the early 1970s, cans were produced by rolling a sheet of steel, soldering and cutting it to size, and attaching both the top and the bottom. In 1972 the industry was revolutionized when aluminium producers perfected a two-piece process in which a flat sheet of metal was pushed into a deep cup and a top was attached. In 1970, steel cans accounted for 88 percent of the metal can production, but by the 1990s aluminium had come to dominate the industry. In 2018, aluminium cans accounted for over 75 percent of metal can production. The manufacturing process of drinks had become even more efficient, producing over 2,000 cans per minute. In addition to production efficiency, aluminium had other advantages over steel: It was easier to shape; it reduced the problems of flavouring; it permitted more attractive packaging because it was easier to lithograph; and it reduced transportation costs because of its lighter weight. Additionally, aluminium was a more attractive recycling material, with a ton of scrap aluminium having almost three times the value of a ton of scrap steel. Four global companies supplied aluminium to can producers: Alcoa, Alcan, Reynolds, and Kaiser. Two of these companies, Alcoa and Reynolds, also manufactured aluminium containers. Exhibit 1 shows Denver's performance for the past five years. EXHIBIT 1: Financial Performance: 2014-2018 (Dollars in Millions) 16% 2014 2015 2016 2017 2018 Net sales $1,126 $1,127 $1,428 $1,624 $1,763 Gross margin $183 $ 178 $ 207 $253 $ 294 Gross margin as percentage of net sales 16% 16% 15% 17% Operating income $ 115 $ 99 $111 $ 136 $146 Operating income as percentage of 19% 15% 16% 18% 21% stockholders' equity Administrative Systems The administrative systems of Denver are considered under the following sections: values, organization structure, human resource policies, and reward systems. The company's values and, over the years, they remained constant (see Exhibit 2). While the values clearly stated that the firm's first duty was to shareholders, they also underwrote a culture in which customers, suppliers, and especially employees were treasured assets. In fact, all employees were encouraged to become shareholders by participating in the profit- sharing plan. Denver expected employees to work hard and help it succeed, but it treated them well, believing people would be fair and honest if they were treated fairly and honestly. Employees were praised for good work and urged to develop their skills. The company offered a tuition reimbursement program to help them continue their education. Managers kept their office doors open to signal their accessibility. They encouraged open communication and tried to keep company discussions free of politics. These and other measures enabled Denver to enjoy a high level of trust between its workers and managers. Organization Structure Denver considered its organization structure to be flat. Its profit-sharing plan, for example, recognized only four basic levels: production, administrative, professional, and executive. This and the fact that the company preferred smaller plants fewer than 150 employees made it easier for employees to communicate with each other. It also helped them to identify with, and commit to Denver. Plant managers enjoyed considerable autonomy, operating their facilities as individual profit centers. Some functions, such as purchasing, were centralized because it was more economical for the company to do so. Similarly, human resource services were shared because this allowed Denver to provide the same services companywide-a move that especially benefited new acquisitions. Exhibit 3 shows the organization chart for the Aluminium Can division. Human Resource Policies At Denver, managers weren't the only key decision-makers. Production workers on the employee councils also participated in various managerial decisions. Workers were appointed to the councils at most plants. They met at least once a month to talk about critical issues, such as plant safety, and conveyed this information to their fellow employees every quarter. One of their primary responsibilities was to decide whether new employees should become permanent. New workers were required to complete a 90-day probationary period before they were eligible for permanent status. During this time, council members discussed the individual's job performance with his or her co-workers. If the comments were favorable, the council approved a permanent hire by majority vote. Exhibit 2: Denver's Philosophy Earnings: The first corporate goal for Denver Corporation is to earn money for its shareholders and increase the value of their investment. We believe that the best measurement of the accomplishment of our goal is consistent growth in earnings per share. Our Golden Rule: We treat our customers, employees, investors, and suppliers, as we would like to be treated. People: We are dedicated to the belief that people are our most important asset. We believe people respond to recognition, opportunity to grow, and fair compensation. We believe that compensation should be directly related to job performance and therefore use incentives, profit sharing or otherwise, in every possible situation. From employees we expect an honest day's work for an honest day's pay. In filling job openings, every effort is expended to find candidates within Denver, its divisions or subsidiaries. Customer: Without the customer and his need for our products and services we have nothing. We will exert every effort to see that the customer's quality and service requirements are met. Once a commitment is made to a customer, every effort is made to fulfil that obligation. Suppliers: We cannot operate profitably without those who supply the quality raw materials we need for our products. From a pricing standpoint, we ask only that suppliers be competitive in the marketplace and treat us as they do their other customers. We are loyal to suppliers who meet our quality and service requirements through all market situations. Organization: We believe in a divisionalised organizational structure with responsibility for performance resting with the head of each operation. All managers are given authority to accomplish their responsibilities within our corporate goals and objectives. We believe in a small corporate staff and support group to service the needs of our shareholders and operating units as requested. Communication: We communicate through every possible channel with our customers, employees, shareholders and operating units as requested. Citizenship: Denver Corporation practices good citizenship at all levels. We conduct our business in a professional and ethical manner when dealing with customers, neighbours, and the general public worldwide. We encourage all our people to actively participate in community affairs. We support worthwhile community causes. As a result, Denver was very customer focused. Workers produced high-quality products and gave attentive service. Once approved, the new employee drew a salary, rather than an hourly wage, and became eligible for the profit-sharing plan. Managers could make recommendations or, if circumstances warranted it, fire the employee. But, generally, they acknowledged that workers on the production "floor were better positioned to evaluate how well other employees performed. Relationships between councils and managers were cordial. Managers appreciated the unique perspective that production workers brought to problems. They enjoyed working with them as team members. Employees, in turn, responded with trust and openness. Workers who wanted to move up the ladder had plenty of opportunity at Denver. The company filled 95 percent of its job openings with internal candidates. Getting promoted depended largely upon merit. Promotion-minded employees were encouraged to further their personal and professional development by taking courses and assuming other jobs throughout the company. People with common sense, who could lead and work well with people, were considered management material; these skills outweighed product knowledge. Exhibit 3: Organisation chart for the Aluminum Can division. President Vice President Manufacturing Vice President Purchasing Vice President Finance and Control Vice President Human Resources and infrastructure Vice President Sales Plant 1 Division Manager Plant 2 Division Manager Plant 3 Division Manager 1 Performance Evaluations and Incentives The Finance and control office generates variance reports monthly. Denver Beverages has a sophisticated information system that automatically generates reports based on input downloaded daily from each plant. Plant managers in the organization also can manually generate the reports. Most managers generate variance reports several times during the month, allowing them to solve problems before the problems get out of control. Denver management reviews the variance reports, looking closely at over-budget variance problems. Plant managers are questioned only about over-budget items. Management believes that this ensures that the plant managers are staying on top of problem areas, and that this keeps the plants operating as efficiently as possible. One week after the variance reports are generated, plant managers are required to submit a response outlining the causes of any variances and how they plan to prevent the problems in the future. If a plant manager has repeated problems, corporate management might send a specialist to the plant to work with the plant manager to solve the problems. Denver management has devised what it thinks is an effective system to motivate plant man- agers. First, plant managers are promoted only when they have displayed outstanding performance in their current position. Second, monetary incentives reward plant managers for reaching profit goals. Finally, charts produced monthly display budgeted items versus actual results. Although not required to do so, most plant managers publicise the charts and use them as a motivational tool. The charts allow department supervisors and staff to compare activities in their department to similar activities in other plants around the world. Required: 1. Decentralization is lauded as important to good management. But it is not without its problems. Is Denver Corporation decentralised? What are the advantages and disadvantages of decentralisation to Denver Corporation? (7 marks) 2. Comment on management control systems at Denver Corporation from the standpoint of how they help the company to outperform its competitors. (8 marks) 3. Evaluate Denver's incentive compensation system. Does the present system motivate Plant managers to make decisions which are consistent with the strategy of the firm? If not, make specific recommendations to improve the system. (7 marks) 4. Assume that Denver is considering improving its performance measurement system. Develop a balanced scorecard for Denver Corporation that reflects the company's competitive advantage. Identify two objectives and one performance indicator for each objective. State clearly any assumptions that you need to make. (8 marks) 5. Explain why an incentive package with only monetary rewards may not promote goal congruent behaviour among the managers. Describe any two types of other incentives which Denver Corporation may want to consider incorporating in their incentive package. Briefly explain how each of these other incentives will motivate managers to be more goal-congruent. (10 marks) (Total: 40 marks)