Question: Section One (Matching) For each expression on the left, choose the letter of the appropriate control chart on the right. 1. (See pp. 329-336) Errors

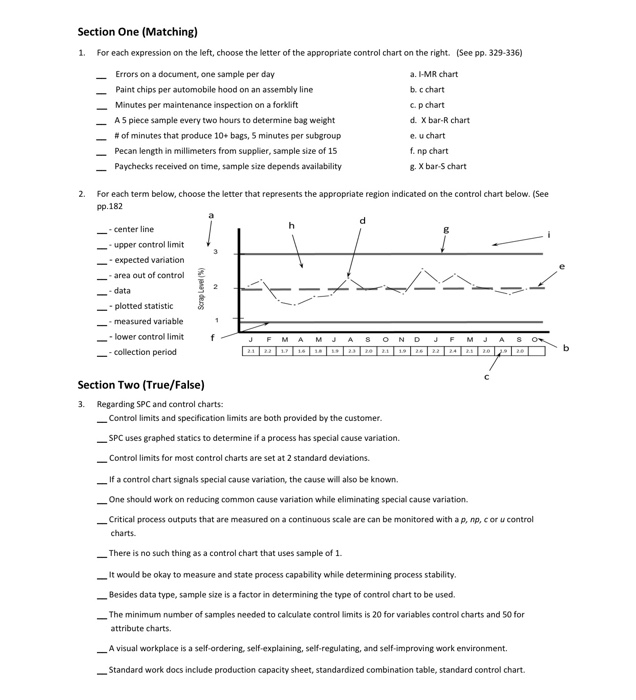

Section One (Matching) For each expression on the left, choose the letter of the appropriate control chart on the right. 1. (See pp. 329-336) Errors on a document, one sample per day a. I-MR chart Paint chips per automobile hood on an assembly line b. c chart Minutes per maintenance inspection on a forklift c.p chart A5 piece sample every two hours to determine bag weight d. X bar-R chart #of minutes that produce 10+ bags, 5 minutes per subgroup e. u chart Pecan length in millimeters from supplier, sample size of 15 f. np chart g. X bar-S chart Paychecks received on time, sample size depends availability For each term below, choose the letter that represents the appropriate region indicated on the control chart below. (See 2. pp.182 d -center line upper control limit expected variation -area out of control - data plotted statistic measured variable lower control limit 22 114 collection period 25 C Section Two (True/False) 3. Regarding SPC and control charts Control limits and specification limits are both provided by the customer SPC uses graphed statics to determine if a process has special cause variation. Control limits for most control charts are set at 2 standard deviations. If a control chart signals special cause variation, the cause will also be known. One should work on reducing common cause variation while eliminating special cause variation. Critical process outputs that are measured on a continuous scale are can be monitored with a p, np, c or u control charts There is no such thing as a control chart that uses sample of 1. It would be okay to measure and state process capability while determining process stability. Besides data type, sample size is a factor in determining the type of control chart to be used. The minimum number of samples needed to calculate control limits is 20 for variables control charts and 50 for attribute charts A visual workplace is a self-ordering, self-explaining, self-regulating, and self-improving work environment. Standard work docs include production capacity sheet, standardized combination table, standard control chart. ()ndes Section One (Matching) For each expression on the left, choose the letter of the appropriate control chart on the right. 1. (See pp. 329-336) Errors on a document, one sample per day a. I-MR chart Paint chips per automobile hood on an assembly line b. c chart Minutes per maintenance inspection on a forklift c.p chart A5 piece sample every two hours to determine bag weight d. X bar-R chart #of minutes that produce 10+ bags, 5 minutes per subgroup e. u chart Pecan length in millimeters from supplier, sample size of 15 f. np chart g. X bar-S chart Paychecks received on time, sample size depends availability For each term below, choose the letter that represents the appropriate region indicated on the control chart below. (See 2. pp.182 d -center line upper control limit expected variation -area out of control - data plotted statistic measured variable lower control limit 22 114 collection period 25 C Section Two (True/False) 3. Regarding SPC and control charts Control limits and specification limits are both provided by the customer SPC uses graphed statics to determine if a process has special cause variation. Control limits for most control charts are set at 2 standard deviations. If a control chart signals special cause variation, the cause will also be known. One should work on reducing common cause variation while eliminating special cause variation. Critical process outputs that are measured on a continuous scale are can be monitored with a p, np, c or u control charts There is no such thing as a control chart that uses sample of 1. It would be okay to measure and state process capability while determining process stability. Besides data type, sample size is a factor in determining the type of control chart to be used. The minimum number of samples needed to calculate control limits is 20 for variables control charts and 50 for attribute charts A visual workplace is a self-ordering, self-explaining, self-regulating, and self-improving work environment. Standard work docs include production capacity sheet, standardized combination table, standard control chart. ()ndes

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts