Question: Set Fixed Capacity Theoretically, it is a simple decision to determine the number of 3D printers needed for the next quarter. Specifically, divide the projected

Set Fixed Capacity

Theoretically, it is a simple decision to determine the number of 3D printers needed for the next quarter. Specifically, divide the projected demand by the number of bikes that can be produced by a single 3D printer, and then round up to a whole number. That is:

FORMULA

Fixed capacity required for next quarter = Number of 3D printers needed to meet demand

Number of 3D printers needed to meet demand = Projected demand for quarter Quarterly production capacity of a 3D printer

There are two other factors that will determine the number of 3D printers needed in the future, worker productivity and overtime.

If workers are not motivated, it will slow down the number of bikes that can be produced in a day and quarter. As a result, additional printers and workers might be needed to compensate for the lost operating capacity.

On the other hand, the use of overtime will allow production to go beyond an 8-hour day. By adding one or more hours to the workday, it will be possible to get more production out of the available printers. Of course, overtime will negatively affect labor costs and productivity (fatigue).

You will learn more about these issues next quarter when you make plans for your production.

YOUR TASK

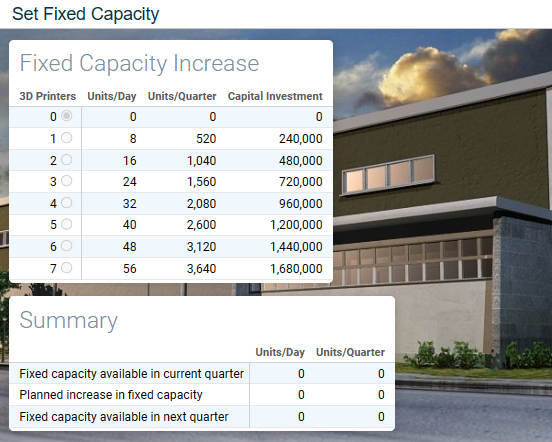

In the current quarter, you have one very important tactical decision to make: an investment in the capacity of your production facility. How many 3D printers will you order for the next quarter?

It takes one quarter to have a 3D printer produced by the supplier and have it shipped to the production facility.

You currently have zero (0) fixed capacity. At the very least, one 3D printer will need to be ordered; two might be desirable.

DECISION TIP

During your first test market, it is not likely that your firm will sell more than 6 bikes per day over the 78 potential selling days of the quarter (the store will run 6 days per week for the 13 weeks of the quarter). That is a total of 468 bikes for the entire quarter (6 * 78 = 468).

It will take a quarter or two to learn how to sell to this new market and build up your name recognition. Therefore, you will not need to create a large production facility at this time. Also, it is not financially practical to purchase more than three 3D printers.

It is important to always be looking into the future and forecasting your demand requirements one or two quarters out. As your distribution expands, plan on adding more fixed capacity. As you add new brands, create better advertising, and expand your sales force, you should also consider production expansions.

The decision to increase fixed capacity has a one-quarter delay. For example, if you decide to purchase one printer, 520 units of capacity, in the current quarter, the change in fixed capacity will not actually be completed until the start of the next quarter.

Summary

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts