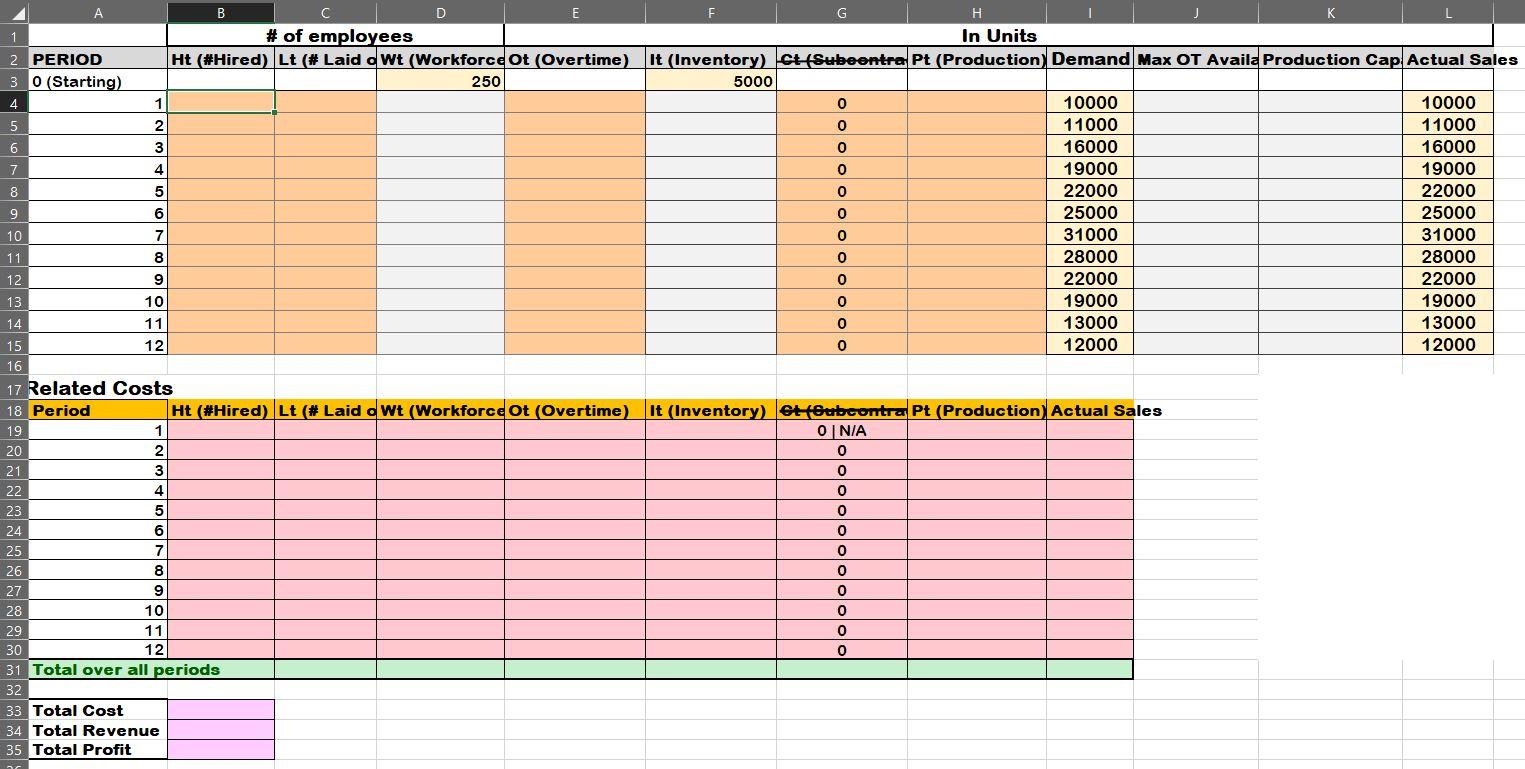

Question: Set-up the constraints that will be required to create an optimal production schedule. Assume actual sales are same as demand values. For your convenience, I

Set-up the constraints that will be required to create an optimal production schedule. Assume actual sales are same as demand values. For your convenience, I have also uploaded the data on Google Sheets accessible here:

https://docs.google.com/spreadsheets/d/1lR8amqv0_sPpc_L9XtadpYMajU_uM2ppEdhmavZEH2M/edit?usp=sharing

A similar question was answered on CHEGG here by Expert Ramjakhar: https://www.chegg.com/homework-help/questions-and-answers/question-set-constraints-required-create-optimal-production-schedule-assume-actual-sales-d-q59983975?trackid=p7XRlnOH

Overtime, hiring, layoffs, are allowed. Backordering and SUBcontracted are NOT allowed; That is, there must be enough inventory in each month to supply that month's expected demand. In Period 12, the ending inventory must be 5000 units.

YOU ARE NOT REQUIRED TO USE EXCEL-SOLVER. Just provide the constraints for any of the following variables given the information below:

| Costs | |

| Regular Time Labor | 15 |

| Overtime Labor | 22 |

| Inventory carrying cost (per unit per month) | 3 |

| Material cost (per unit) | 40 |

| Selling Price (per unit) | 125 |

| Hiring Cost (per new employee) | 1000 |

| Lay-off cost (per laid off employee) | 2000 |

| Starting Inventory | 5000 |

| Desired Ending Inventory | 5000 |

| Overtime Limit (number of units produced per employee) | 10 |

| Production Capacity (per employee per month) | 80 units |

| Starting Workforce | 250 workers |

| Labour hours per unit | 2 |

| MAX overtime per month per employee, HOURS | 20 |

| # of working days per month | 20 |

| # of hours per day | 8 |

| DEMAND 10000 |

| 11000 |

| 16000 |

| 19000 |

| 22000 |

| 25000 |

| 31000 |

| 28000 |

| 22000 |

| 19000 |

| 13000 |

| 12000 |

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts