Question: Several years have passed during which VG has continuously improved its quality. They now meet the standards for a Six Sigma process, ie. Cp more

Several years have passed during which VG has continuously improved its quality. They now meet the standards for a Six Sigma process, ie. Cp more than 2. which is equivalent to a maximum of 3.4 defective pellets per lot of one million. What is the standard deviation of the process now?

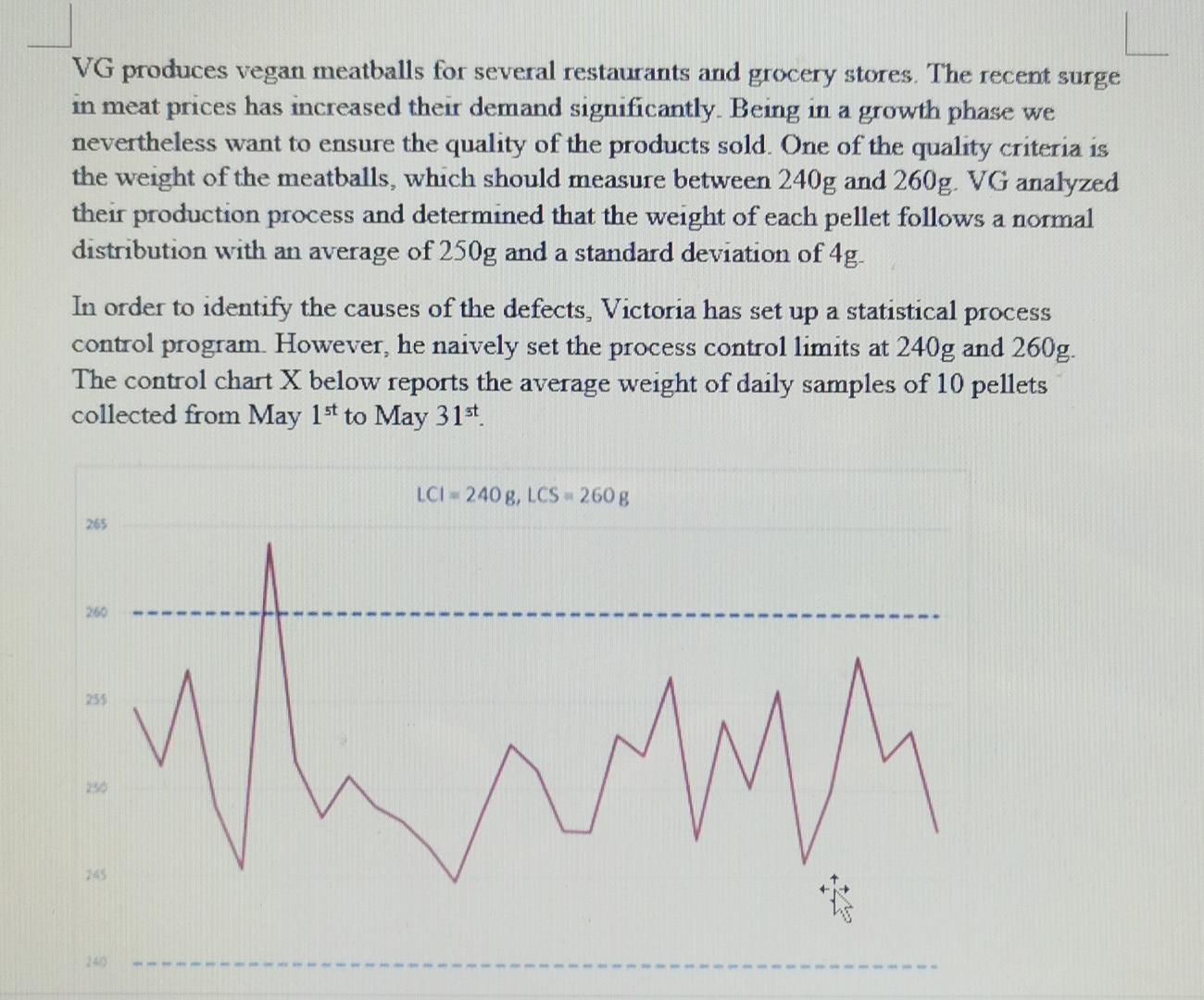

VG produces vegan meatballs for several restaurants and grocery stores. The recent surge in meat prices has increased their demand significantly. Being in a growth phase we nevertheless want to ensure the quality of the products sold. One of the quality criteria is the weight of the meatballs, which should measure between 240g and 260g. VG analyzed their production process and determined that the weight of each pellet follows a normal distribution with an average of 250g and a standard deviation of 4g. In order to identify the causes of the defects, Victoria has set up a statistical process control program. However, he naively set the process control limits at 240g and 260g. The control chart X below reports the average weight of daily samples of 10 pellets collected from May 1st to May 31st a LCI 240g, LCS-260g 265 260 255 MMA 25 24Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts