Question: Show me the steps to solve : A compressed air system is planned for a factory in Reso Finland. Compressed air consumption estimated is taken

Show me the steps to solve :

A compressed air system is planned for a factory in Reso Finland. Compressed air consumption estimated

is taken to X Nms The compressed air must be produced centrally and distributed via a pipeline system

stem with overpressure Y bar. The primary options are to use piston compres

rer to produce the compressed air as the investment cost is relatively low. piston compressor

sorer cannot run continuously due to cooling problem. This is supposed to be solved by

install two parallel compressor lines running alternately. For the compression to be used

a twostage compressor with intermediate cooling and a heat exchanger for postcooling. As

an alternative design, a system with only one compressor line has been proposed. To

do not overheat the twostage compressor in this case you have a pressurized container so that a

continuous flow of Y bar compressed air can be obtained. The maximum pressure in the containers is provisionally set

to Z bar. In both cases, the compressors must run for minutes and rest for the same amount of time.

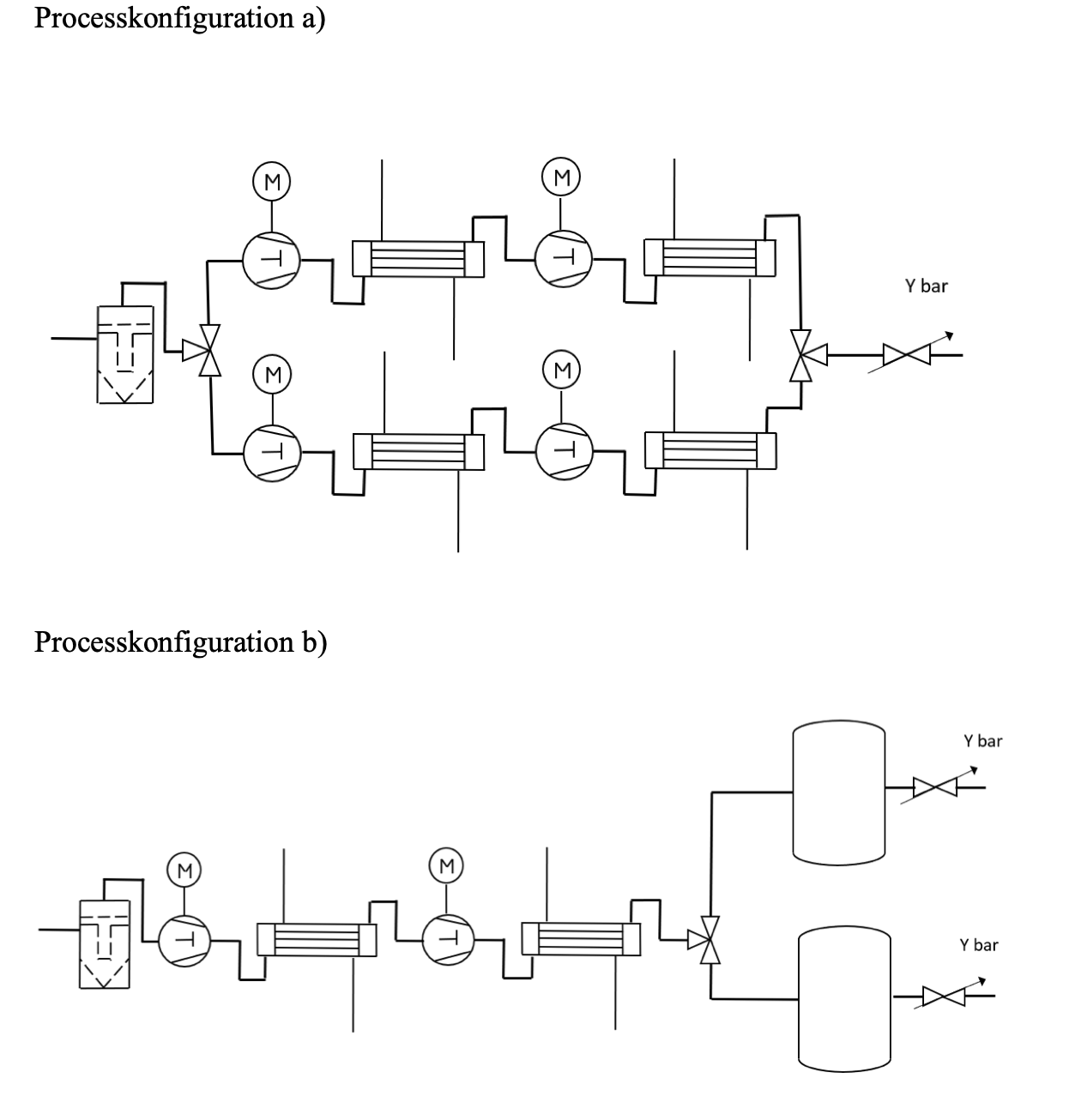

Processkonfiguration a

Processkonfiguration b

Your task is to make an initial estimate of the process economy in the two cases by

to estimate the total cost of the facility based on the price of the components

which are included in the attached figures but not valves and pipes and operating costs

them p Determine which of the designs is economically more advantageous by comparing

bring their present values. The economic lifespan is set at four years and calcu

the interest rate is p

Calculate the required compressor power using the formula for compression of an ideal

gas. For calculations of required engine power for the compressors, you can assume that the

the isentropic efficiency is Select the intermediate pressure between the two compression

the steps as the geometric mean of the initial pressure and the final pressure. Assume that

the air is cooled down to deg C in both the intercooler and the aftercooler. You

may make the simplification that the pressure in the compressed air tank is constant during the filling, but

justify your choice of counter pressure. Make the further simplification that the temperature is constant

in the compressed air tank.

The heat exchangers can be assumed to be of the tube heat exchanger type. Heat transfer coefficient

either can be estimated at WmK for a heat exchanger where a pressurized gas flows in

the tubes. The heat transfer is given by QFUATln F is a function of the currents' tem

temperatures but use F in your calculations. Tln is the logarithmic mean tempe

the rate difference. The temperature of the cooling water varies between and deg C during the year. Assume

that the temperature of the outgoing cooling water must not exceed deg C Compressed air reservoir

lar can be assumed to have a height that is twice the diameter. When you estimate the cost

these use the correlations in Table of Towler and Sinnott. The electricity price, inclusive

transmission and taxes are for the factory ckWh The cooling water cost for the factory is set

to cm

Document your assumptions well, eg for how the process should be run.

X

Y

Z

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock