Question: show steps please In your effort to develop an aggregate plan for the next three months you consider the following data (each employee makes 10

show steps please

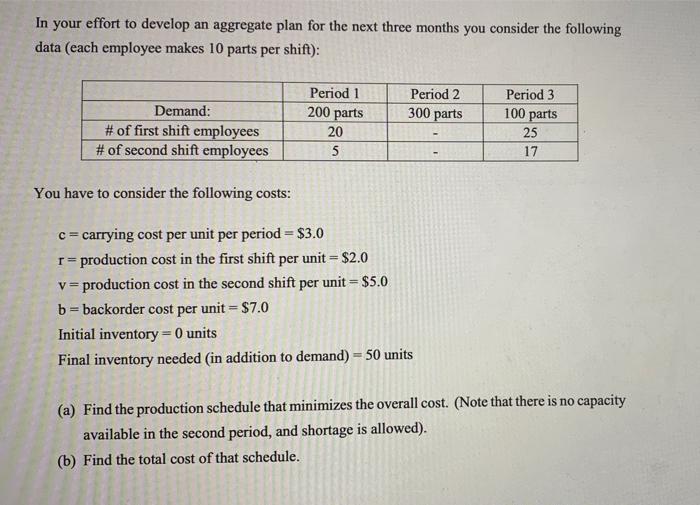

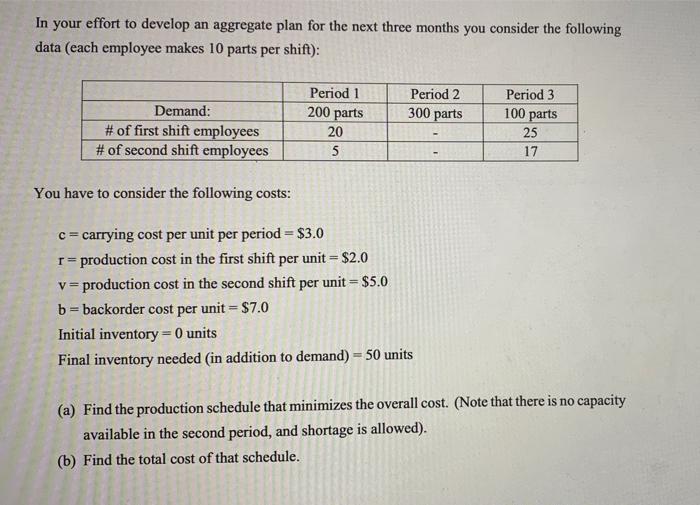

In your effort to develop an aggregate plan for the next three months you consider the following data (each employee makes 10 parts per shift): Period 1 Period 2 200 parts 300 parts Demand: # of first shift employees # of second shift employees Period 3 100 parts 25 17 20 5 You have to consider the following costs: c=carrying cost per unit per period = $3.0 r=production cost in the first shift per unit = $2.0 v=production cost in the second shift per unit = $5.0 b = backorder cost per unit = $7.0 Initial inventory = 0 units Final inventory needed (in addition to demand) = 50 units (a) Find the production schedule that minimizes the overall cost. (Note that there is no capacity available in the second period, and shortage is allowed). (b) Find the total cost of that schedule

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock