Question: Sir Kindly solve it on a A4 sheet, Please don't reupload the answer Thank you An equimolar liquid mixture of benzene and toluene is separated

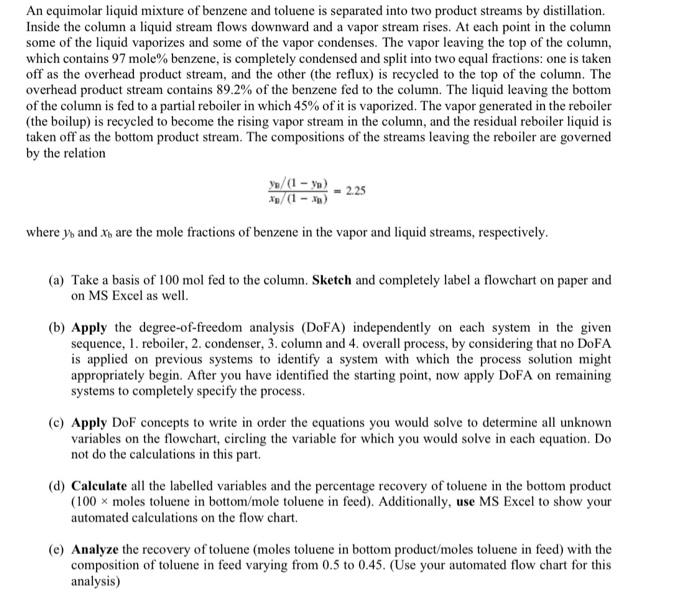

An equimolar liquid mixture of benzene and toluene is separated into two product streams by distillation. Inside the column a liquid stream flows downward and a vapor stream rises. At each point in the column some of the liquid vaporizes and some of the vapor condenses. The vapor leaving the top of the column, which contains 97 mole% benzene, is completely condensed and split into two equal fractions: one is taken off as the overhead product stream, and the other (the reflux) is recycled to the top of the column. The overhead product stream contains 89.2% of the benzene fed to the column. The liquid leaving the bottom of the column is fed to a partial reboiler in which 45% of it is vaporized. The vapor generated in the reboiler (the boilup) is recycled to become the rising vapor stream in the column, and the residual reboiler liquid is taken off as the bottom product stream. The compositions of the streams leaving the reboiler are governed by the relation 2.25 p/(1-3) where y) and X1 are the mole fractions of benzene in the vapor and liquid streams, respectively. (a) Take a basis of 100 mol fed to the column. Sketch and completely label a flowchart on paper and on MS Excel as well. (b) Apply the degree-of-freedom analysis (DoFA) independently on each system in the given sequence, 1. reboiler, 2. condenser, 3. column and 4. overall process, by considering that no DOFA is applied on previous systems to identify a system with which the process solution might appropriately begin. After you have identified the starting point, now apply DoFA on remaining systems to completely specify the process. (e) Apply DoF concepts to write in order the equations you would solve to determine all unknown variables on the flowchart, circling the variable for which you would solve in each equation. Do not do the calculations in this part (d) Calculate all the labelled variables and the percentage recovery of toluene in the bottom product (100 moles toluene in bottom/mole toluene in feed). Additionally, use MS Excel to show your automated calculations on the flow chart. (e) Analyze the recovery of toluene (moles toluene in bottom product/moles toluene in feed) with the composition of toluene in feed varying from 0.5 to 0.45. (Use your automated flow chart for this analysis)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts