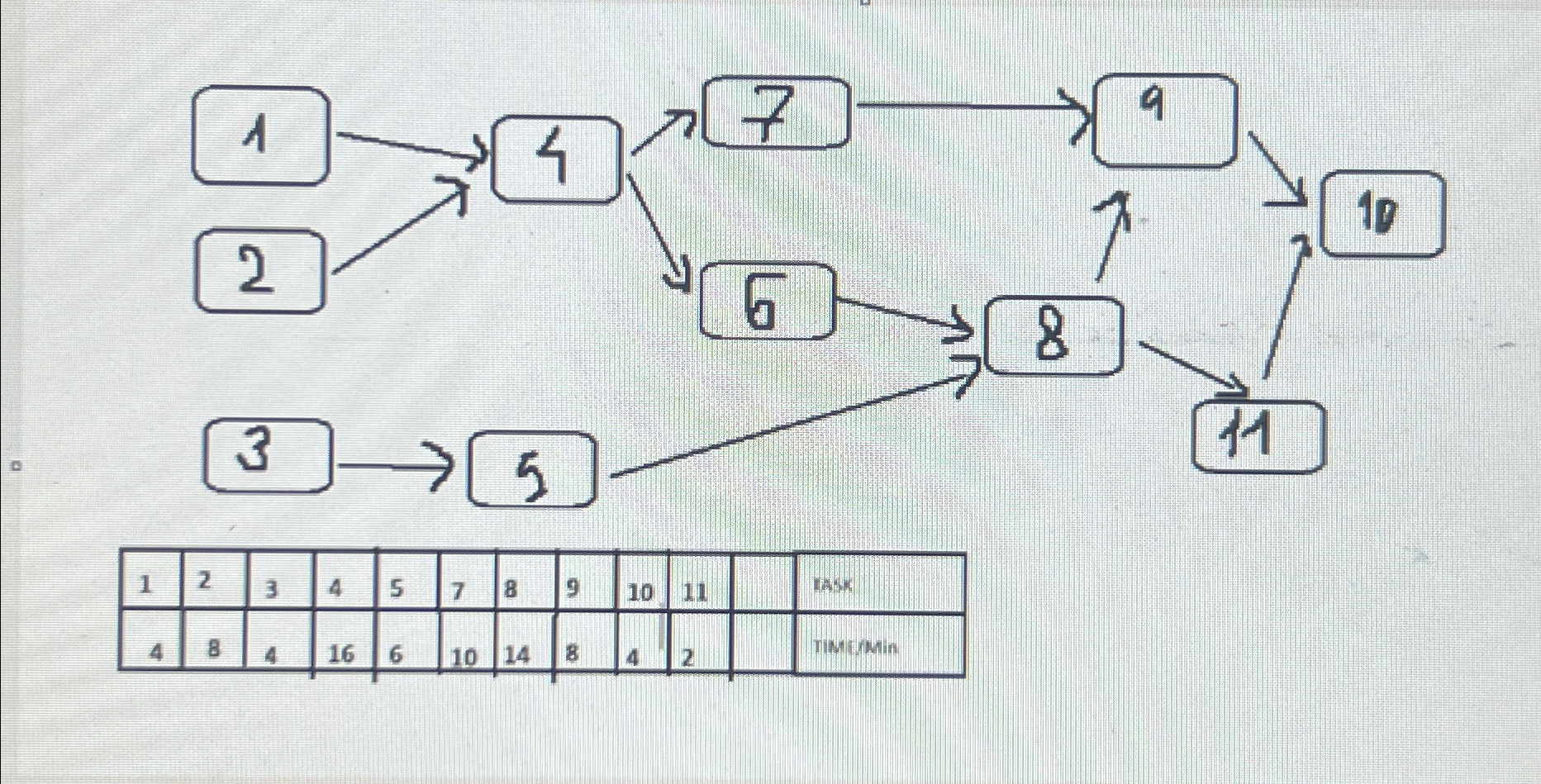

Question: So total 5 workers working for whole stations. First worker working on 1 , 2 , 3 tasks, Second worker working on 4 , 5

So total workers working for whole stations. First worker working on tasks, Second worker working on tasks. Third worker working on tasks. Fourth worker working on th Last th working workinh on stations. Time is given in diagram. Now first thing we need to focus on is: For thise setup what is the cycle time?

Management wants to meet the demand efficiently. Use Longest processing time rule to balance the assembly line. Start calculating number of stations ans resolving ties by selecting the task with the higher number.

Can the current setup meet the demand of assembling products per day with three hours shifts breaks?

Lastly After finding a balanced assembly line setup, how can production be increased further?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock