Question: Source Based on Hesada and Rao Development Maturing System for Construction of School Future Forest Products Journer September 2003, 47-54 Most wooden chairs are made

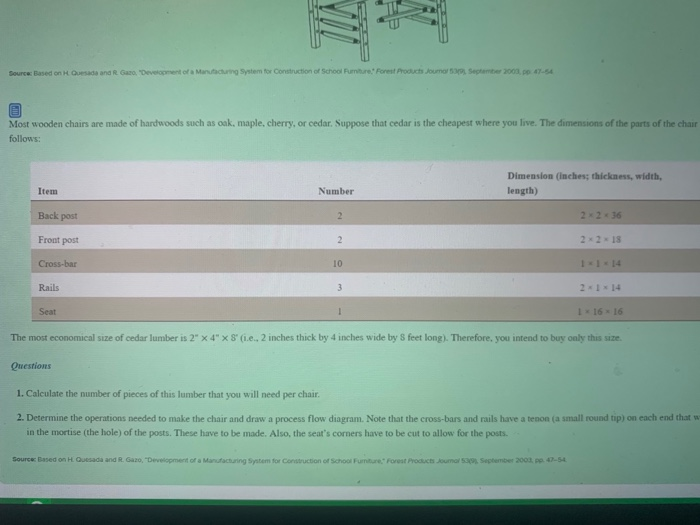

Source Based on Hesada and Rao Development Maturing System for Construction of School Future Forest Products Journer September 2003, 47-54 Most wooden chairs are made of hardwoods such as oak, maple, cherry, or cedar. Suppose that cedar is the cheapest where you live. The dimensions of the parts of the chair follows: Dimension (inches; thickness, width, length) Item Number Back post 2x2x36 Front post 2 2 * 2 * 18 Cross-bar 10 Rails Seal 1x 16 x 16 The most economical size of cedar lumber is 2" x 4" X 8' (i.e., 2 inches thick by 4 inches wide by S feet long). Thereforeyou intend to buy only this size. Questions 1. Calculate the number of pieces of this lumber that you will need per chair. 2. Determine the operations needed to make the chair and draw a process flow diagram. Note that the cross-bars and rails have a tenon (a small round tip) on each end that w in the mortise (the hole) of the posts. These have to be made. Also, the seat's corners have to be cut to allow for the posts. Source Based on H Quesada and R. Gazo, "Development of a Manufacturing System for construction of School Future Forest Products Joumars. September 2003, pp. 49-54 Source Based on Hesada and Rao Development Maturing System for Construction of School Future Forest Products Journer September 2003, 47-54 Most wooden chairs are made of hardwoods such as oak, maple, cherry, or cedar. Suppose that cedar is the cheapest where you live. The dimensions of the parts of the chair follows: Dimension (inches; thickness, width, length) Item Number Back post 2x2x36 Front post 2 2 * 2 * 18 Cross-bar 10 Rails Seal 1x 16 x 16 The most economical size of cedar lumber is 2" x 4" X 8' (i.e., 2 inches thick by 4 inches wide by S feet long). Thereforeyou intend to buy only this size. Questions 1. Calculate the number of pieces of this lumber that you will need per chair. 2. Determine the operations needed to make the chair and draw a process flow diagram. Note that the cross-bars and rails have a tenon (a small round tip) on each end that w in the mortise (the hole) of the posts. These have to be made. Also, the seat's corners have to be cut to allow for the posts. Source Based on H Quesada and R. Gazo, "Development of a Manufacturing System for construction of School Future Forest Products Joumars. September 2003, pp. 49-54